|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

I need to ask you guys on how to remove engine head, turbo, manifold, exhaust header, and all exhaust piping. and oil pan oil filters fuel filters. also how to on turbo rebuild and new gasket installations for head, turbo, exhaust header, oil pan. should I install longer oil filter? what else should I look into replacing? its 240,000km transmission seems its slipping when its under load for example on highway speed dropping below 100km/h gear slipps.

|

|

#2

|

|||

|

|||

|

Most of your questions have been asked by others. Conduct a search regarding the OM603 engine. It was also used in the W124 (300D) and W126 (300SDL, 350SD, 350SDL). Owning a 1995, S350 I have found that there is little W140/OM603 specific information available online.

What is wrong with the engine? Sounds like the first step could be removing the engine and trans.

__________________

Present 1987 300SDL 1991 300SL 1990 560SEL 2001 ML320 Past 1969 200D 1979-82 1983 300SD 1984-85 1972 250C 1982-02 1995 S350 2011 1997 S320 2012 Last edited by NJ300sdl; 10-02-2011 at 09:50 PM. |

|

#3

|

||||

|

||||

|

The procedure isn't something that can be practically typed into a forum response. Get your hands on a factory shop manual. There are critical steps like the sequence of loosening the cam towers. Get it wrong and you'll unwittingly have a DOHC engine.

I'm not aware of a longer oil filter. You're limited by the size of the oil filter housing. What other work you should do depends on what work you're doing in the first place and why you feel you need to do that work. For example, you talk about the transmission slipping. Why are you pulling the head if the problem is with the transmission? Sixto 87 300D |

|

#4

|

||||

|

||||

|

I think there is a big exhaust leak because I can smell em inside while driving so I have to open the windows. and I think because of the leak the turbo doesnt work or the pressure is not there to actually make turbo work. and I think maybe the intake from turbo to engine (the part that is on top of engine) is clogged with loads of dirt and gunk blocking air way? where should I look for when there is exhaust leak? cause I have to push pedal to the floor to get normal power going. and car pools to passenger side pretty hard so I am guessing its not just alignment. what part is loose or needs to be replaced in alignment correction?

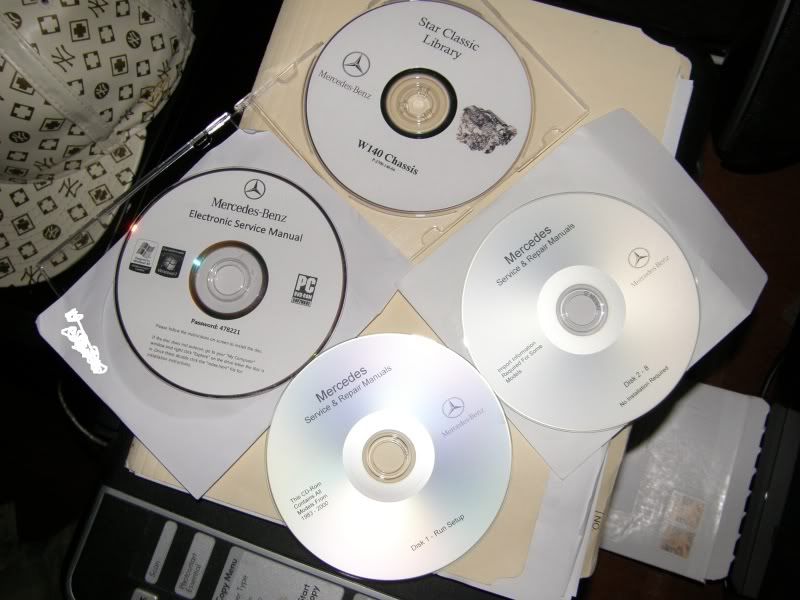

I have some CD and DVD that came with car which one should I use?

|

|

#5

|

||||

|

||||

|

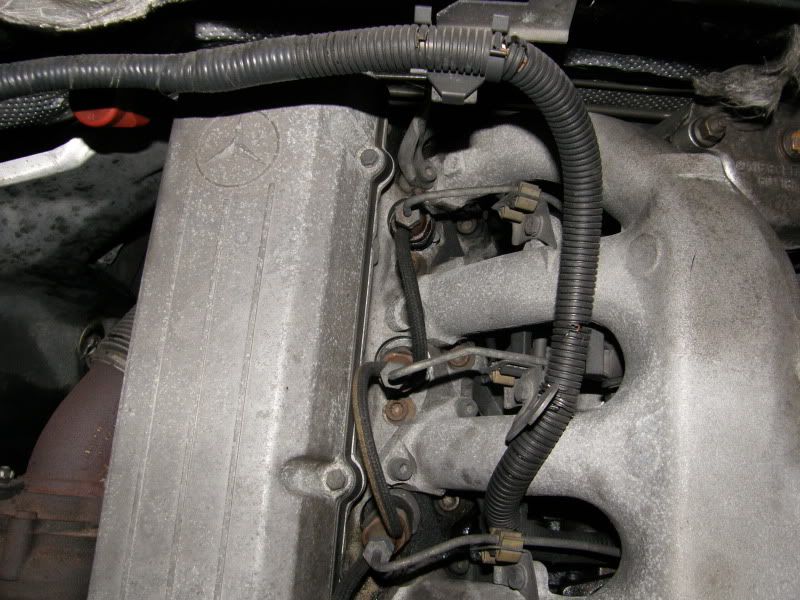

The discs labeled Service & Repair Manuals look like good starting points.

Low power in an engine with electronic boost control is, IMHO, not worth investigating. I highly recommend this modification - http://www.peachparts.com/shopforum/diesel-discussion/212097-wastegate-actuator-swap-om602-962-a.html for your sanity. As a simple test, temporarily hook up the wastegate actuator directly to a vacuum source. Hook up a boost gauge also if you can. If engine power is restored or at least improved, the problem is likely with the EDS detecting a fault and holding back boost. I am not aware of diagnostic procedures that don't require esoteric electronic test equipment. The crossover pipe and intake manifold can have a substantial coating of tar yet cleaning them yields little to no performance improvement. One place to look for an exhaust leak in the engine bay is the accordion connector between the #1-4 exhaust manifold runners and the #5-6 runners. It's the small accordion in this picture -  As for the pulling, have you checked tire pressure? It's at lot of work to list everything that can wear or become damaged in the steering and front suspension systems. Maybe you hit a pothole or large bump and bent a tie rod or control arm. Really difficult to say from the symptom. Sixto 87 300D Last edited by sixto; 10-04-2011 at 11:29 PM. |

|

#6

|

||||

|

||||

|

to check the exhaust leak on accordion connector. Can I do this by visual test only? or do I need to apply soapy water and see if it bubbles? or actually take it out and blow on it to see if it leaks ? or use flash light to see if any gas comes out while running the engine? what are the chance of the exhaust header actually have hole or crack? and what if turbo is shot? should I rebuild it or just buy new one thats maybe in bigger size? will bigger turbo need new computer tuning?

|

|

#7

|

||||

|

||||

|

wow, this is a large undertaking if you have no experience with this type of work.

you are going to need to strictly follow the instructions in the manuals. I think you should stick to one issue at a time, and please post pictures as you go. also, before you take any bolts loose, photograph them, and where they came from, it'll make reassembly go simpler.

__________________

John HAUL AWAY, OR CRUSHED CARS!!! HELP ME keep the cars out of the crusher! A/C Thread "as I ride with my a/c on... I have fond memories of sweaty oily saturdays and spewing R12 into the air. THANKS for all you do! My drivers: 1987 190D 2.5Turbo 1987 560SL convertible 1987 190D 2.5-5SPEED!!!  1987 300TD 2005 Dodge Sprinter 2500 158"WB 1994GMC 2500 6.5Turbo truck... I had to put the ladder somewhere! |

|

#8

|

||||

|

||||

|

You can find an exhaust leak by looking for soot. You don't have the lung capacity to find an exhaust leak by blowing. Or maybe you can exhale 500 cfm long enough to find a leak

If the turbo is shot you repair or replace it. You're a long way from that decision given the more likely case that the ECU is holding back performance. The original turbo is properly sized for the fuel system. There's no point in upgrading the turbo until you increase fuel delivery. Fuel delivery isn't controlled by the ECU except at idle, and you don't want to defeat that. If you have to upgrade the turbo, upgrade to VNT rather than a larger turbo. Please apply vacuum directly from the engine vacuum pump to the turbo wastegate actuator and see if performance improves, BUT KEEP THE ENGINE BELOW 4000 RPM. Then attach a boost gauge to the line between the intake manifold and injection pump and let us know what pressure is indicated under hard acceleration. Until you do these simple tests, you're throwing solutions at a problem you haven't defined. Sixto 87 300D |

|

#9

|

||||

|

||||

|

Why don't you just start with the basics and make sure the ALDA is getting signal?

__________________

http://superturbodiesel.com/images/sig.04.10.jpg 1995 E420 Schwarz 1995 E300 Weiss #1987 300D Sturmmachine #1991 300D Nearly Perfect #1994 E320 Cabriolet #1995 E320 Touring #1985 300D Sedan OBK #42 |

|

#10

|

||||

|

||||

|

I have problem trying to do this (Please apply vacuum directly from the engine vacuum pump to the turbo wastegate actuator) I found the one thats now attached to wastegate. but cant find other? man.... any pics?

|

|

#11

|

||||

|

||||

|

The engine vacuum pump is on the front of the engine below the big fuel filter. There are two fittings on the pump; the big one goes to the brake booster, the small one splits to serve a number of systems. Two branches go to the (US LHD) passenger side of the engine bay; one for EGR, one for the turbo wastegate. It doesn't matter which one you redirect to the turbo wastegate.

In this picture, the two fittings to the passenger side have yellow caps. This is not a 92 300SD so it might not be an exact representation.  Sixto 87 300D |

|

#12

|

||||

|

||||

|

I will post pics tomorrow of my engine bay every inch of it and post it up here. so you can circle the area in picture so I know where and what I need to be looking for.

|

|

#13

|

||||

|

||||

|

as I promised here are the pics.

|

|

#14

|

||||

|

||||

|

|

#15

|

||||

|

||||

|

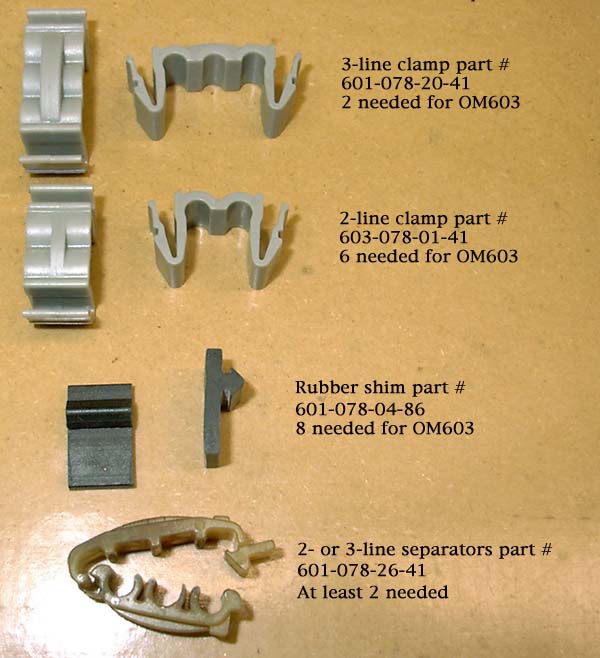

That engine is complicated enough without the WVO plumbing

I see some injector lines aren't clamped to their brackets (pics 18 and 19). Those injector lines are very expensive new and hard to find used. Better get them clamped ASAP. Here's your shopping list -  It also looks like you need some new injector return lines (pics 19 and 20), the braided hose from injector to injector. That should clear the puddles of fuel along injector row. Could be what you smell as exhaust in the cabin. That bit of clear hose between the brake booster vacuum line check valve and hose to the engine shutoff solenoid (pic 22) doesn't look up to the task. Replace it with proper engine bay rated vacuum line before it melts or catches fire. Be very gentle as the entire line has to be replaced if you brake the check valve nipple. IIRC my 93 SD had a MAP sensor tee'd into the boost signal line from the intake manifold to the ALDA. It looks like you have an overboost protection solenoid (pic 24). Temporarily remove and lines to the solenoid and hook them together. See if you get better engine performance. None of your pictures shows the wastegate since it's best viewed from below. There should be a vacuum line coming through the aluminum sheet separating the air cleaner from the engine. It's a separate line from the one to the EGR valve (pic 15). Maybe we can see the wastegate actuator if you remove the air cleaner, airflow sensor and accordion hose to the turbo. Sixto 87 300D |

|

| Bookmarks |

|

|