|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

That is the only jack point with rust like that, the others are fine/solid. This car is a year round driver, and when its on the road it drives awesomely because the prev owner had suspension work done on it, and the engine/tranny are absolutely perfect. Also the climate control was redone (works flawlessly, except for the failed A/C compressor) It also has an absolutely mint interior. Its worth trying to keep it on the road another 5-10 years or so. We want to see it hit and surpass 300k.....

__________________

-diesel is not just a fuel, its a way of life-  '15 GLK250 Bluetec 118k - mine - (OC-123,800) '17 Metris(VITO!) - 37k - wifes (OC-41k) '09 Sprinter 3500 Winnebago View - 62k (OC - 67k) '13 ML350 Bluetec - 95k - dad's (OC-98k) '01 SL500 - 103k(km) - dad's (OC-110,000km) '16 E400 4matic Sedan - 148k - Brothers (OC-155k) |

|

#2

|

||||

|

||||

|

Successful Day of Work!

Tonight we got back to work on the sway project (we're ignoring the jack point issue for the moment, didn't need to raise the car anyways)

We pulled the cables going across out of the way, and the brake line, and removed the brackets successfully, with tons of PB blaster. The nuts were in OK condition, the permenant bolt/threads are just fine and in great shape, thankfully. Brackets came out with no problems, then we pulled the sway bar, wasn't all that difficult at all. WAY easier to maneuver that thing than it is to do the oil cooler lines, those took me almost an hour to snake in back when I did them on my car, the bar took about 3-4 minutes to get out. My dad then went to work for about an hour on the surface rust etc in those areas, and cleaned it up then treated it with the awesome rust converter stuff, its the purple looking stuff in the pictures, it dries to a super hard rustproof black surface. Tomorrow we'll be putting the new bar in, hooking the suspension all together and doing the brackets, then we begin the reinstallation of everything. Horray!!! Below are some pictures of the after-results of tonights work, I forgot to take pics of the sway bar itself, I'll put some in the next update, I'll get some good shots of how it failed/snapped, and also of the side that didn't, but was also in very bad shape/quite corroded. Pics: Our awesome heater that has given us an amazingly comfortable work environment:

__________________

-diesel is not just a fuel, its a way of life-  '15 GLK250 Bluetec 118k - mine - (OC-123,800) '17 Metris(VITO!) - 37k - wifes (OC-41k) '09 Sprinter 3500 Winnebago View - 62k (OC - 67k) '13 ML350 Bluetec - 95k - dad's (OC-98k) '01 SL500 - 103k(km) - dad's (OC-110,000km) '16 E400 4matic Sedan - 148k - Brothers (OC-155k) |

|

#3

|

||||

|

||||

|

Update....

So tonight we went ahead and were getting prepared to reinstall the sway bar and have that all done. Low and behold as we're going through our pile of parts from the stealership we find that, we were given a big order of VOLVO parts for some odd application...( a few HUGE bolts & a big seal ring & some smaller hex bolts...strange indeed $76 worth of stuff according to the sheet attached to them

) Also, the bolts given to us to attach the sway bar to the upper control arm are crud, they are far inferior material to the originals. We can mar them up and score the metal with a small screw driver!! ) Also, the bolts given to us to attach the sway bar to the upper control arm are crud, they are far inferior material to the originals. We can mar them up and score the metal with a small screw driver!!  You can't even make a scratch on the originals.... They also gave us too many metal plates for the rubber bushings. Here is a biggy: They gave us FOUR nuts the size/fit of the bolts that go into the sway bar on the upper control arm(17mm), but NO nuts for mounting the brackets to the car!!!(Huge 19mm) You can't even make a scratch on the originals.... They also gave us too many metal plates for the rubber bushings. Here is a biggy: They gave us FOUR nuts the size/fit of the bolts that go into the sway bar on the upper control arm(17mm), but NO nuts for mounting the brackets to the car!!!(Huge 19mm)  Those four nuts are useless, the bolt screws right into the sway bar! And why would they give us 4 of them???! So tonight we wasted just over an hour of propane and our time. We also have to touch up the paint on the sway bar itself, as they managed to mar it up in many places, appearantly its too hard to ship it in a sheath to protect it or something.... Those four nuts are useless, the bolt screws right into the sway bar! And why would they give us 4 of them???! So tonight we wasted just over an hour of propane and our time. We also have to touch up the paint on the sway bar itself, as they managed to mar it up in many places, appearantly its too hard to ship it in a sheath to protect it or something....  Tomorrow the stealership is getting an UNhappy customer visit....

__________________

-diesel is not just a fuel, its a way of life-  '15 GLK250 Bluetec 118k - mine - (OC-123,800) '17 Metris(VITO!) - 37k - wifes (OC-41k) '09 Sprinter 3500 Winnebago View - 62k (OC - 67k) '13 ML350 Bluetec - 95k - dad's (OC-98k) '01 SL500 - 103k(km) - dad's (OC-110,000km) '16 E400 4matic Sedan - 148k - Brothers (OC-155k) |

|

#4

|

||||

|

||||

|

I did this exact same job on my 85 300SD 2 winters ago. I found nearly the same rust problems and issues that you have found. Mine broke on the same side as yours. A couple of things come to mind:

Don't bother replacing the upper control arms/bushings. I did and didn't have to. You will have to use a giant prybar to get the new sway bar into the upper control arm. That may be difficult in your garage. Once you bolt in the new bushings and cap it will all line up. Don't use any lube oils on the rubber bushings especially the bushings holding the sway bar in place on the chassis. Be careful with the brake line on the chassis it's fragile and old. Don't worry about the rust at this point. Jack it up from the middle front under the main center support. Might have to roll it back some in your situation. The wheels must come off to finish the job. I found so much rust on my car I simply refused to even worry about it. I sprayed in a can or two of Great Stuff foam into every frame hole I could find and every rust hole then sprayed some undercoating over that. Overall one of the most fullfilling jobs to ever undertake for a 126 Chassis for a DIY'er. Keep up the good work.

__________________

Orland Park, IL 1985 300SD 215,000 miles |

|

#5

|

||||

|

||||

|

I don't think we'll need to use a pry bar or take the wheels off. My dad was able to separate the suspension BY HAND without a problem.

(he's a tad strong...) And he plans to jam the sway bar back into the control arm the same way. (he's a tad strong...) And he plans to jam the sway bar back into the control arm the same way.  We are worrying about the rust, left untreated it will only get worse, so off it will go for repairs. We've been following the Factory repair instructions and a haynes manual (only helpful to find torque specs for things  ) and have so far not had any problems. Our biggest problem is the inability of the stealership to get the correct parts..... ) and have so far not had any problems. Our biggest problem is the inability of the stealership to get the correct parts.....  I am heading over there in less than 15 minutes to get on their backs. I am heading over there in less than 15 minutes to get on their backs.

__________________

-diesel is not just a fuel, its a way of life-  '15 GLK250 Bluetec 118k - mine - (OC-123,800) '17 Metris(VITO!) - 37k - wifes (OC-41k) '09 Sprinter 3500 Winnebago View - 62k (OC - 67k) '13 ML350 Bluetec - 95k - dad's (OC-98k) '01 SL500 - 103k(km) - dad's (OC-110,000km) '16 E400 4matic Sedan - 148k - Brothers (OC-155k) |

|

#6

|

||||

|

||||

|

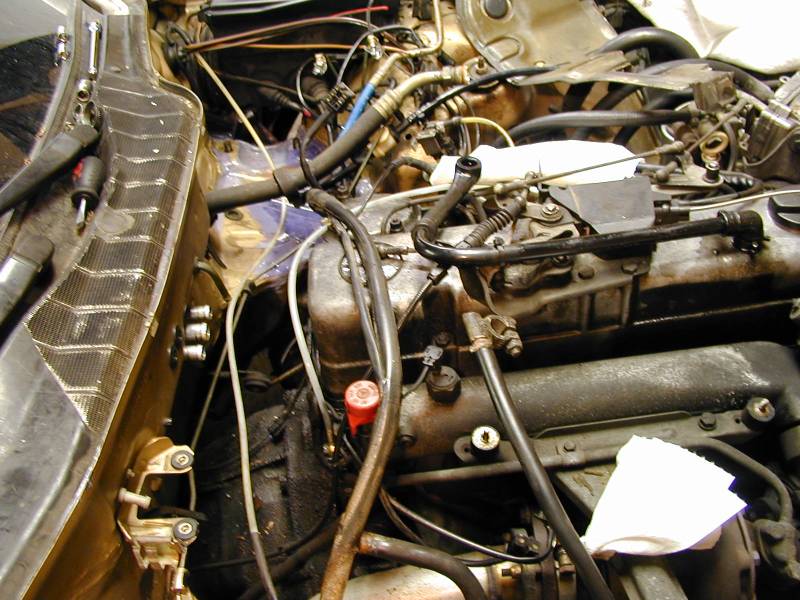

Tonight we installed the new sway bar, we did not need a pry bar, nor to take the wheels off to do the job, and it worked just fine, we did have to pry a tad to get the left bracket on, but that was minor, we got the bar into the upper control arms without a problem. My dad then painted it all in rustoleum nice and spiffy, then we reattached the wires running across the firewall, and the brake line and its brackets, and the water duct for the windshield, then I took these pics and we called it a night.

Next step will be bulkhead reinstallation, then working on getting the climate control components back in, then the brakes and other firewall pieces, then we'll be very close to being done!!  YAY! YAY!Pics from tonight, note the nice new shiny black sway bar...

__________________

-diesel is not just a fuel, its a way of life-  '15 GLK250 Bluetec 118k - mine - (OC-123,800) '17 Metris(VITO!) - 37k - wifes (OC-41k) '09 Sprinter 3500 Winnebago View - 62k (OC - 67k) '13 ML350 Bluetec - 95k - dad's (OC-98k) '01 SL500 - 103k(km) - dad's (OC-110,000km) '16 E400 4matic Sedan - 148k - Brothers (OC-155k) |

|

#7

|

||||

|

||||

|

Man that's one heck of a repair job!!! What exactly does a sway bar do? Sorry but I'm still trying to learn about suspension stuff.

__________________

Seth 1984 300D 225K 1985 300D Donor body 1985 300D Turbo 165K. Totaled. Donor Engine. It runs!!! 1980 300SD 311K My New Baby. 1979 BMW 633csi 62K+++? Dead odo |

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|