|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

Why do some diesels have glowplugs and some not?

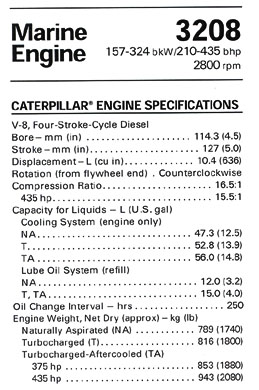

A comment on another thread raises this question in my mind. Why do our 617's have glowplugs but my CAT 3208 doesn't? The CAT smokes a lot more upon startup at all temperatures, but it seems to start at low temperatures when there would be no hope of starting the 617 without glowplugs. I know some diesels have intake heaters etc, but the CAT doesn't. There must be some design difference that permits it to start at low temperatures without glowplugs but I don't know what it is. Can someone enlighten me?

__________________

1977 300d 70k--sold 08 1985 300TD 185k+ 1984 307d 126k--sold 8/03 1985 409d 65k--sold 06 1984 300SD 315k--daughter's car 1979 300SD 122k--sold 2/11 1999 Fuso FG Expedition Camper 1993 GMC Sierra 6.5 TD 4x4 1982 Bluebird Wanderlodge CAT 3208--Sold 2/13 |

|

#2

|

||||

|

||||

|

I got some great help from this forum when I installed a 3208 in a Ford 9000.

http://boatdiesel.com/Forums/index.cfm?Forum_ID=93&CFApp=5&RED=UN1170475349078

__________________

Satan creates nothing: he only ruins everything. He does not invent: he tampers. And his followers are no different ~ Archbishop Carlo Maria Vigaṇ |

|

#3

|

|||

|

|||

|

Glow plugs

Some engines have glow plugs because their compression ratio is to low to start the engine without them. Your Mercedes Benz 617 will typically have a compression ratio of 26:1 when new and this falls over time. My Dodge Ram high output Cummins has a compression ratio of 30:1. Diesel engines squeeze the air making it real hot and larger engines and those with compression ratios of 35 or 40:1 often do not need glow plugs! Also, your Mercedes Benz will be started and stopped several times in a typical day and industrial diesels will run at a steady speed for days at a time. When the air/fuel mixture is squeezed really hard, it will burst into flame. It really isn't good for high compression diesels to be used for stop and go driving. Diesel engines used to drive freezer compressors often have a compression ratio of 50:1 or even more!! These engines do not need glow plugs or intake heaters because once they are started, they won't be shut down until it's time for their maintenance schedule. They go 24/7 nonstop until service time and at a constant RPM! Does this help?

|

|

#4

|

|||

|

|||

|

Quote:

Issue 1: Last time I checked the compression ratio of a 617 is @ 21-to-1 Issue 2: Cummins HO engines have @ 17-to-1 compression ratio Most diesel engines have compression ratios between 18-to-1 and 21-to-1. The law of diminishing returns comes into effect with compression ratios above 24-to-1 or so. The physical structure of the engine becomes so bulky to survive the compression/combustion forces, the combustion chamber shape/size is compromised, peak cylinder pressures exceed whats mechanically practical, etc. at least this is what I have read.... Besides that, the size and power of the starter required to spin an engine like this would be impractical at best. I have no idea why a Cat 3208 doesn't need any preheating but it is an interesting topic. RT

__________________

When all else fails, vote from the rooftops! 84' Mercedes Benz 300D Anthracite/black, 171K 03' Volkswagen Jetta TDI blue/black, 93K 93' Chevrolet C2500HD ExCab 6.5TD, Two-tone blue, 252K |

|

#5

|

|||

|

|||

|

All of the 2 cycle Detroits that I'm familiar with never had any glow system. But, they wouldn't start below 32F. without ether unless they were brand spanking new.

I believe the need for glow plugs is mandatory on an IDI diesel due to the very cold environment of the prechamber. A DI diesel has an even chance of starting without glow plugs, but, it's no certainty on any of them when it gets really cold. Ether is the mode of choice to get them going and it doesn't appear to have any negative consequences if used judiciously. |

|

#6

|

||||

|

||||

|

Just a bit o' clarification.....

Quote:

The injector does not spray a pattern as most do...instead it "spritzes" a straight stream.... The stream of fuel oil is designed to hit a little ball within the pre-combustion chamber.... This little ball is also designed to retain heat when the engine is running.... The straight shot of fuel oil is vaporized upon contact with the HOT little ball...... The pencil type of glow plug heats this little ball...unsure as to how the older loop style work, for certain.... So when the engine is cold, the glow plug heats the little ball (initially), the fuel is squirted onto the ball, and vaporized.....and combustion occurs when the compression rises to it's ignition point.....after the engine is running the heat of combustion maintains the little ball temperature..... SB Note: I think (note think!) that the reason we get the nailing issue is because a piece of carbon (or other trash) causes a portion of the injected fuel to miss the little ball....and to ignite further into the combustion chamber.....and at a slightly later time.....

__________________

Diesels: '85 300D, "Max, Blue Benz", 155K, 27.0 MPG '84 190D 2.2, "Eva, Brown Benz", 142K, 40.2 MPG '77 240D (parts car) '67 Eicher ES 202 Tractor "Otto" (2cyl, Air Cooled, 30HP) Gassers: '94 Ford F-150, "Henry", 170K (300 Six) 17.5 MPG '85 190E 2.3, 148K....Parts Car '58 Dodge W300M Powerwagon (Flat Fenders) Less than 10 MPG |

|

#7

|

|||

|

|||

|

Some very old CAT engines have a 14:1 ratio. I'm told they were very difficult to start.

|

|

#8

|

|||

|

|||

|

Quote:

I don't understand the exact reason why lowering compression and increasing boost allows more fuel and therefore more power without breaking stuff but apparently it does. RT

__________________

When all else fails, vote from the rooftops! 84' Mercedes Benz 300D Anthracite/black, 171K 03' Volkswagen Jetta TDI blue/black, 93K 93' Chevrolet C2500HD ExCab 6.5TD, Two-tone blue, 252K |

|

#9

|

|||

|

|||

|

Quote:

|

|

#10

|

||||

|

||||

|

Cat 3208 n/a had a ratio of 16/1. If I remember correctly the design of the piston top was shaped in a way to promote easier cold starts.

__________________

Satan creates nothing: he only ruins everything. He does not invent: he tampers. And his followers are no different ~ Archbishop Carlo Maria Vigaṇ |

|

#11

|

|||

|

|||

|

That's true! I also forgot, some of these engines had ether start systems! That's why it says "do not use starting fluids that contain ether"!

|

|

#12

|

|||

|

|||

|

I operate a DD 6V92 W/ turbo & blower and it will start at 40F. It is plugged in below that, or just kept running on the fast idle ( 1,100 rpm).

I have heard that the compressions on the DD with the turbo were lower than without the turbo. I am wondering as to why ???

__________________

Gary Experience is something you get, Just after you needed it.... '99 E300 295K, '83 300D 220K, '75 240D 185K sold '80 MCI Bus Conv DD 6V92TA, w/4 cyl. Kubota diesel GenSet 12.5KW |

|

#13

|

|||

|

|||

|

With the turbo forcing air into the cylinder under pressure, the actual compression ratio goes up. A lower static compression ratio allows more air to be stuffed into the cylinder without pushing compression pressures beyond what's best/safe/needed.

|

|

#14

|

|||

|

|||

|

Forced Induction, Thanks

So if some one was to install a blower on a std DD then he runs the risk of damage, How do they "lower" the compression, shorter connecting rod? Diff piston head? You got me to wondering.. But not like Stevie yet,,,

__________________

Gary Experience is something you get, Just after you needed it.... '99 E300 295K, '83 300D 220K, '75 240D 185K sold '80 MCI Bus Conv DD 6V92TA, w/4 cyl. Kubota diesel GenSet 12.5KW |

|

#15

|

|||

|

|||

|

There is already a supercharger or blower on all naturally or turbocharged Detroit Diesel 2 cycle engines. By utilizing the blower and the scavenger ports that are in the piston liners as well as cast into the engine block, the need for exhaust valves are eliminated. Everyone should google Detroit 2 Cycle and there are more indepth explanation of the processes involved.

__________________

DDC/MTU....Setting the pace 1985 300cd 1983 300d...aka "The Yummymummymobile"....Wifes ride 2006 Wesmac 38' Sportfisherman, Single DDC/MTU 12V-2000 1500 hp |

|

| Bookmarks |

|

|