|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

Thoughts on Injector Cleaning

I am attempting to evaluate the benefits of periodically cleaning diesel injectors. By "cleaning," I mean disassembling and brushing/scraping as specified in the MB 617.95 Engine Manual. I notice that one vendor sells a small tool kit for the job.

Can anyone provide any insight? I am more than happy to put forth the effort to do the job is the benefits outweigh the risks by a reasonable margin. I just don't wnat to open a can of worms if it is not justifiable. |

|

#2

|

||||

|

||||

|

I asked the Bosch shop I go to about this when I had my injectors rebuilt for the 82. They mentioned that if an injector is working properly and has been in operation for under 100k, do not touch it and that 'only bad things can happen'.

They were of the opinion that a preventative pop and spray test every 25k would be ok to do, but probably overkill, and if any showed issues to then clean them. They thought the best preventative maintenance was to use a good injector cleaner additive (they carry Stanadyne stuff) or to use biodiesel at least occasionally. dd

__________________

------------------------------- '85 300D, 'Lance',250k, ... winter beater (100k on franken-Frybrid 3 Valve Kit) '82 300D, 'Tex', 228k body / 170k engine ... summer car '83 300TD Cali Wagon 210k, wife's car |

|

#3

|

|||

|

|||

|

They are right, taking them apart 'only bad things can happen'.

Even the acids on your fingers can etch the unprotected nozzle metal and ruin them. |

|

#4

|

||||

|

||||

|

I had mine taken apart at 100K. Actually only 1 was taken apart. The other 5 passed pop pressure and spray pattern test. At 200K, they passed the test but I wanted to go with Bosio nozzles since they were getting long in the tooth.

__________________

01 Ford Excursion Powerstroke 99 E300 Turbodiesel 91 Vette with 383 motor 05 Polaris Sportsman 800 EFI 06 Polaris Sportsman 500 EFI 03 SeaDoo GTX SC Red 03 SeaDoo GTX SC Yellow 04 Tailgator 21 ft Toy Hauler 11 Harley Davidson 883 SuperLow |

|

#5

|

||||

|

||||

|

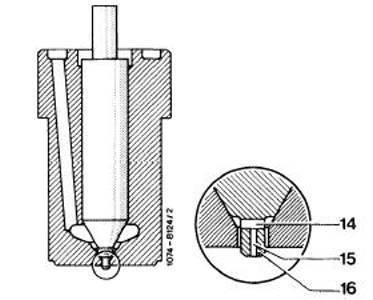

The stock Nozzles have a Tiny central hole drilled thought the center of the Pintel. If these get plugged up (as happened on my car) in effects your idle. Ounce they are plugged the holes have to be cleaned by hand with the correct size music wire (what size to use is in the Factory CD Repair manual). If you do not use the right size and strength of wire you can enlarge the hole or break the wire off inside.

Probably if you do that Diesel Purge on a regular basis you can keep the holes cleaned out so they do not plug to begin with. Any time the Injectors are taken apart the parts for the individual Injector should be kept with that Injector and the flat surfaces in side of the Injectors should be Lapped flat again before they are assembled again. Pic of the holes  I have seen the kit sold by M-source and doubt if it is of much use. We had no such kit when I worked in a Fuel Injection Shop for any Injectors except the skinny Caterpillar Pencil type Nozzles. The Pencil type Nozzle kit had a scraper that goes inside of the Injector and was supposed to clean out the internal seat in side of the Nozzle. It would only help maybe 1 out of 100 nozzles. The reason is that when the Nozzle Pintel is opening and closing (up and down) bits of carbon and even bits of metal get trapped between the Pintel seating area and the seating area of the Nozzle and hammer themselves into the seat pitting and eroding the seating area. No manual cleaner or scraper can fix that. My Boss even bought some equipment to regrind and Lapp in the Nozzle and Pintel seats on Detroit Diesel Injector Nozzles. Even with this equipment only about 1 out of 4 nozzles could be reused.

__________________

84 300D, 82 Volvo 244Gl Diesel Last edited by Diesel911; 11-04-2008 at 11:52 PM. |

|

#6

|

|||

|

|||

|

Thanks to all who responded. It looks like the risks exceed the benefits, so I will let those sleeping dogs lie.

|

|

#7

|

||||

|

||||

|

Question is how many miles you have. Nothing wrong with taking it out and having it tested. In my case, with 1 out of 6 bad injectors, I think I gained about 1 mpg after it was cleaned at 100K. So it might be worth it. This is why I don't like additives and other snake oils. They will never tell you how your injector is. I compare them to sweeping the room in the dark. You might think you got it all but you will never be sure. Turn on the light and you will know for sure. In this case, the test will show a good or bad pattern. No ifs, ands or buts about it.

__________________

01 Ford Excursion Powerstroke 99 E300 Turbodiesel 91 Vette with 383 motor 05 Polaris Sportsman 800 EFI 06 Polaris Sportsman 500 EFI 03 SeaDoo GTX SC Red 03 SeaDoo GTX SC Yellow 04 Tailgator 21 ft Toy Hauler 11 Harley Davidson 883 SuperLow |

|

#8

|

||||

|

||||

|

I just cleaned my injectors today and i was very disappointed to see that all the pintle holes were open and clear. My injectors are original and my car is very high mileage. I thought for sure that I could get some improvement from the cleaning but alas they were in pretty good shape.

But I did tweak the "cam phasing" on cyl 1 after I put it all back together and was able to stop the pinging noise I always heard at idle and now the engine doesn't rock at all anymore! super smooth! |

|

#9

|

||||

|

||||

|

This seems like as good a time as any to stop lurking and post....

I obtained a beautiful 1984 300SD with 351K on it from JohnHef a few months ago, and he's been good enough to help me get some DIY maintenence experience. Anyhow there's a decent diesel shake at idle, and since it as far as we know it has the original injectors, I'm going to check all the pop pressures and spray patterns. To that end I just built a diesel injector pop tester out of a bottle jack as per the instructions here (but I tapped the jack nut for 3/4" NPTF instead of welding) and just pulled the injectors from a dead 617 John had on the floor of his garage last weekend. My plan is to check all 10 and put the best 5 in the SD (possibly grinding down/ shuffling shims if the pop pressures are too far off from one another). I've been thinking about injector cleaning since i'm going to have them out anyways and can experiment on the spare injectors before I pull the ones from the SD... I saw the cleaning instructions Diesel911 referred to in the manual but i'm a little leery about marring the lapped surfaces where the needle and nozzle body meet. Have any of you guys tried/ heard of someone trying to clean the disassembled nozzle components using acetone in an ultrasonic cleaner? I've got one in the lab that I work in, and was thinking I'd give that a shot unless one of you can come up with good reason not to. It seems like an ideal solution for getting carbon deposits out of the nooks and crannies without messing up the lapped surfaces any more than they already may be. Also, do any of you know where to find ISO 4113 test oil? I'd rather not use diesel in my pop tester if i can avoid it. Thanks in advance, i'll post some before/ after pictures of spray patterns once the whole process is done. |

|

| Bookmarks |

|

|