|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

How to build a diesel injector pop tester

I just finished building an injector pop tester. I thought I would post instructions here on how it was made since I couldn’t find anything online written for people like me who want to build one but don’t know anything about anything. (

<-- me ) <-- me )The reason for building a tester is to see what pressure your injectors spray at (they should be matched to each other within 3 bar), to see their spray pattern (the spray should be well atomized and narrow), and to see if they leak. You can pay a diesel shop to do this, but it is costly ($60-$70 for the test, and $60+ per injector to adjust if needed). I actually took mine to a shop earlier this year and they said they were fine, but I wanted to see for myself.  If improperly built or used this tool could explode or squirt you in the eye or something, so the usual disclaimer applies:

Bottle Jack vs. Grease Gun There appear to be two common designs for homemade injector testers – they are either based on a grease gun or a bottle jack to generate pressure. I initially tried the grease gun approach because it seemed easier (it has threaded fittings on it, a reservoir to hold fluid, etc.) but after unsuccessfully trying 3 different models of grease gun, and after using the bottle jack version, I would advise against using a grease gun. The grease guns don’t seem to be designed to pump something as thin as diesel, and their seals leak all over the place. They can’t hold pressure for more than a fraction of a second so rapid continuous pumping is required. The best grease gun I got could only reach 75 bar of pressure with diesel fuel, and fuel was seeping from it everywhere at the time. The main challenge with building a bottle jack tester is that you need to have a means of attaching a threaded fitting to the giant nut at the top of the jack. You must either have the tools to drill and tap giant holes (3/4” to 1”), or you need to have welding equipment. I had neither so I had to take the parts to a welding shop and pay them to do it. This isn’t the place for plastic pipe and epoxy; you need a proper connection here due to the high pressures involved (potentially over ~150 bar / 2000 PSI). Come up with a plan before you start buying stuff! This was the most time consuming part of the project. The home depot plumbing aisle won’t help you no matter how long you stare at it… edit: here's a good animation of how a bottle jack works - http://www.hyjacks.net/animation.htm Gauge Sizing Many of the commercial injector testers you can buy seem to come with a 5000PSI (350 bar) gauge. In my opinion, this seems useless for Mercedes injectors; you want to balance the injectors to within 3 bar, but the scale markings on a 350 bar gauge are 10 bar apart, so the scale of the gauge is too large to let you measure something as small as 3 bar in a repeatable manner. I went with a 150 bar gauge (my injectors are supposed to be set to 115-125 bar). On this gauge, the markings are 2.5 bar apart and you can easily measure to ~1 bar. Don’t get an incorrectly sized gauge or your tester will be useless. The gauge I used was inexpensive, however the pressures I measured from my injectors were within 1 bar of what was reported by the diesel injection shop that tested them earlier this year, so the gauge appears to be reasonably correct.  Instructions Parts List (see picture below). Most parts are available at Princess Auto.

The first step is to disassemble the bottle jack by loosening the giant nut on the top. Remove it carefully and do not hang on to the jack by the outer cylinder. It is full of disgusting oil and the only thing holding it to the jack is the nut you’re removing. Carefully pick the jack up by the base and dump out the oil. The outer cylinder should just pull off – it is not fastened in any way. Be sure to keep the plastic seal at the base. Pull out the piston and dump out any additional oil inside. You won't be reinstalling the piston.  End of part 1 of 2 (split due to forum post length limit)

__________________

1989 250TD Wagon 5-speed, 160,000mi ::: Dark gray metallic / black cloth 1984 190D-2.2 5-speed, 287,000mi ::: Silver-blue metallic / black MB-tex ::: SOLD

Last edited by cornblatt; 06-07-2008 at 02:42 PM. Reason: Added info |

|

#2

|

|||

|

|||

|

Part 2 of 2

Part 2 of 2 (split due to forum post length limit)

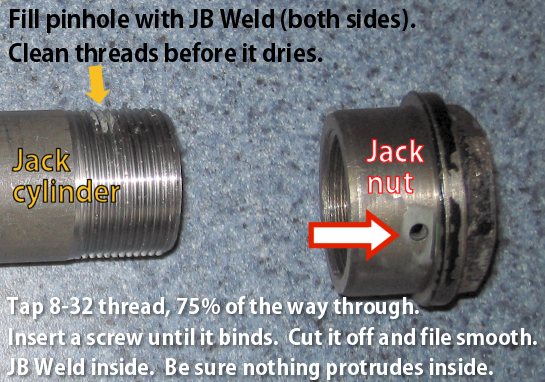

The giant nut from the top of the jack contains an o-ring that you should remove. Then you must somehow attach a threaded fitting to the top of the jack nut. I used a 1” NPT male to ¾” NPT female reducer and had it welded. You might be able to tap the top of the jack nut and thread in a fitting, but the metal isn’t that thick and it could be tricky to get a tight seal. This joint is under a lot of pressure and needs to be secure; you will definitely need to either tap it and screw in a fitting or have it welded (real welding, not JB-Weld). Mine was welded on the outside, so just to be safe, I sealed it with a layer of JB weld on the inside (the welder warned me that sometimes tiny cracks in the weld may cause a leak so I thought the extra layer of JB weld couldn’t hurt). The jack nut also has a tiny hole on the side that you will need to plug. Drill the tiny hole out and tap it for 8-32 thread, but only tap it ¾ of the way through. Then, insert an 8-32 threaded screw until it binds. Cut it off and file it smooth. Seal it inside with JB Weld. Don’t insert the screw so deep that it extends inside the nut, or you won’t be able to reassemble the jack. The jack’s inner cylinder has a very very tiny pinhole hidden in the threads that you will need to plug. I super-cleaned it and sealed it with JB Weld inside and out. Be sure to clean up the threads before the JB Weld hardens.  Take the outer cylinder of the jack and attach some sort of supply line where you can add diesel fuel. It should have a hole in the side already, plugged with a rubber stopper. I JB-welded a PEX 90° copper plumbing fitting to the side (the fluid here is not under pressure so in this case JB weld alone is suitable).  To make a fluid reservoir, I took an old food can and JB welded another PEX fitting to the bottom. Inside the can, the PEX fitting extends up about 3/8” and I attached a piece of cloth to the top of it. This is important as it lets any debris settle to the bottom of the reservoir without risk of it being drawn into the tester. The inline fuel filter should be installed between the reservoir and the jack. Dirt is your enemy – even the tiniest speck of dirt can cause the pintle in the injector to seize up.  You should also prepare a jar into which the injectors can spray. I drilled out the lid of a tall glass food jar so that it would thread onto the injector. The fuel that sprays out of the tester is at extremely high pressure and can penetrate your skin and cause poisoning, so the use of the jar prevents accidental contact with the spray. In addition, the spray is so fine that you produce a fog of diesel that lingers for tens of minutes; the jar captures this so you don’t inhale it. Plus, faulty injectors can spray at crazy angles, so keeping the nozzle down inside the jar makes sure you don’t get an unexpected blast of diesel in your eye. Clean everything, and put it all together as shown in the picture, using LOTS of teflon tape on every threaded fitting, particularly on the VW fitting where it connects to the #6 ORB fitting, and the top of the jack cylinder where the jack nut screws on. Before you begin testing, fill the reservoir with diesel, and pump the jack handle. You should not have an injector installed at this time. Pump until ~1/2 cup of fuel has been run through the system, to ensure that any dirt has been flushed out. I initially tried testing injectors with something other than diesel (e.g. canola oil), but the injectors respond much differently to vegetable oil – they just spray a solid stream and dribble. Since the car runs on diesel, testing the injectors with diesel seemed to be the best way to simulate how they work when they’re in the car.  Note that the two pictures below are taken approximately 1/20th of a second apart.  If you have Bosch DN 0 SD 240 nozzles with the hole-type pintle, an initial jet sprays out the hole in the pintle prior to the actual spray – if you have these nozzles and see this jet, it isn’t a sign of a malfunctioning injector! This can sometimes be hard to test for; I found it worked well to build the pressure really slowly and carefully – this lets you see the initial jet before the pressure gets high enough that the injector pops. The valve on the tester was intended for disconnecting the gauge during rapid pumping so it doesn’t get damaged by banging around with wild pressure changes. I put it in because the tester in the Mercedes factory service manual had one. But, after building the tester, I don’t think it is really necessary (and at $17, the most expensive item in the parts list). The bottle jack tester holds pressure so well that the needle doesn’t fly around even during rapid testing – it just wiggles right near the injector’s pop pressure. Once you stop pumping, the pressure holds just a hair below the injector’s pop pressure (it gradually declines over a time period of a minute). If your tester is leakier then maybe you need the gauge… With the tester, I was able to get all of my injectors balanced to within 1.5 bar. They were 4.5 bar apart before adjustment.

__________________

1989 250TD Wagon 5-speed, 160,000mi ::: Dark gray metallic / black cloth 1984 190D-2.2 5-speed, 287,000mi ::: Silver-blue metallic / black MB-tex ::: SOLD

Last edited by cornblatt; 06-06-2008 at 07:40 PM. Reason: Added pictures |

|

#3

|

|||

|

|||

|

You Are The Man!

|

|

#4

|

|||

|

|||

|

Would this also be feasible on the car?

take out glow pugs, attach different hardlines, put each injector in a can, rotate crank? you wouldn't get the measured accuracy for sure.. but just for a pattern test? |

|

#5

|

||||

|

||||

|

Great how-to!

__________________

1991 350SDL. 230,000 miles (new motor @ 150,000). Blown head gasket  Tesla Model 3. 205,000 miles. Been to 48 states! Past: A fleet of VW TDIs.... including a V10,a Dieselgate Passat, and 2 ECOdiesels. 2014 Cadillac ELR 2013 Fiat 500E. |

|

#6

|

||||

|

||||

|

nice write-up...

__________________

1984 123.193 372,xxx miles, room for Seven. 1999 Dodge Durango Cummins 4BTAA 47RE 5k lb 4x4 getting 25+mpgs, room for Seven. |

|

#7

|

||||

|

||||

|

Excellent job,the neatest i have seen of home built pop testers! I have an old WW2 vintage navy surplus one that looks like it was made from a jack,but it actually was supplied by Buda diesel engine company,still working after all these years.The nice one you built will probably still work 50yrs from now too. My $.02 Don

__________________

Red Green "This is only temporary,Unless it works!"  97 E300D 157000 miles 87 300TD ?141k? miles |

|

#8

|

||||

|

||||

|

cornblatt,

Yours puts mine to shame  (post #11 in the linked thread). (post #11 in the linked thread).anyone know how to use a diesel pop tester?

__________________

The Golden Rule 1984 300SD (bought new, sold it in 1988, bought it back 13 yrs. later) |

|

#9

|

|||

|

|||

|

Masterfully done.

__________________

1963 Ford F100 - Cummins Swap? 1985 Mercedes 300SD - 210K 1992 Ford Festiva - 92K 2001 Ninja 250 - 8K |

|

#10

|

|||

|

|||

|

Quote:

I wish I had seen that thread before I started! It would have saved me a lot of trial-and-error steps. There's a post on there (#16) that describes almost the same method I ended up using, but I did it wrong 4 times before finally arriving at that method...

__________________

1989 250TD Wagon 5-speed, 160,000mi ::: Dark gray metallic / black cloth 1984 190D-2.2 5-speed, 287,000mi ::: Silver-blue metallic / black MB-tex ::: SOLD

|

|

#11

|

||||

|

||||

|

I'm glad you liked mine. It has served well, for me, and a couple of friends' cars, also.

Yours brings DIY to a pro level plane, however; and your pictorial write-up is soooooooo good. Oddly enough, I had made one, initially, that I had the upper nut/adapter welded onto, but it leaked so badly that I was forced to go to the large pipe threader to get that part to seal.

__________________

The Golden Rule 1984 300SD (bought new, sold it in 1988, bought it back 13 yrs. later) |

|

#12

|

||||

|

||||

|

Well done.

I did the DIY and it didn't last 6 tests prompting me to get a factory one.

Another hazard is not just fuel in the eye. If you have any injected into the skin (quite possible even at HALF normal pressure) it can be FATAL. So, keep fingers away from the stream.

__________________

1987 300D (230,000 mi on a #14 head-watching the temp gauge and keeping the ghost in the machine) Raleigh NC - Home of deep fried sushi! |

|

#13

|

|||

|

|||

|

I am thinking about putting one of these together . Sean - What failed ?

BTW -I wonder if the fittings (brass ?) on this one are rated for high pressures ? Would using a portapower type pump from HF or Northerntool (like this - http://www.northerntool.com/webapp/wcs/stores/servlet/product_6970_200333147_200333147 ) be OK ? . If so , it appears to eliminate need for the big tap and or welding . Quote:

Last edited by rkpatt; 08-18-2008 at 11:25 AM. |

|

#14

|

||||

|

||||

|

Quote:

There is a recommended non tox test fluid (not normal veggie oil)

__________________

Cheers, Robert |

|

#15

|

|||

|

|||

|

Hey, thanks for taking the time to post your tester info. It helps alot. I have been thinking of building a tester but thinking is far a I progressed. Good pictures.

85 190 d 84 190 d 87 300td |

|

| Bookmarks |

|

|