|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

Injection Pumps 101

I am in the process of rebuilding my 84 300SD engine and wanted to get a better understanding of the dos and donts of my IP pump. There does not seem to be a lot of detailed information avalable on it and I understand that there are settings on the pump that can only be made be a tech with the proper test equipment.

I was hoping this thread will give a better idea on how it works and what things can be inspected and adjusted. So I am going to point out what I know and ask a lot of questions. I took several pics of the pump out of my new engine. The pic below is the end of the pump next to the oil filter.  I have some more pics to come. Thanks, Jim |

|

#2

|

|||

|

|||

|

More of my pics....

|

|

#3

|

||||

|

||||

|

You may find this useful as well :

http://superturbodiesel.com/std/ip-full-load-adjustment-procedure-for-om61x-series-t-189.html

__________________

http://superturbodiesel.com/images/sig.04.10.jpg 1995 E420 Schwarz 1995 E300 Weiss #1987 300D Sturmmachine #1991 300D Nearly Perfect #1994 E320 Cabriolet #1995 E320 Touring #1985 300D Sedan OBK #42 |

|

#4

|

||||

|

||||

|

Picture #1

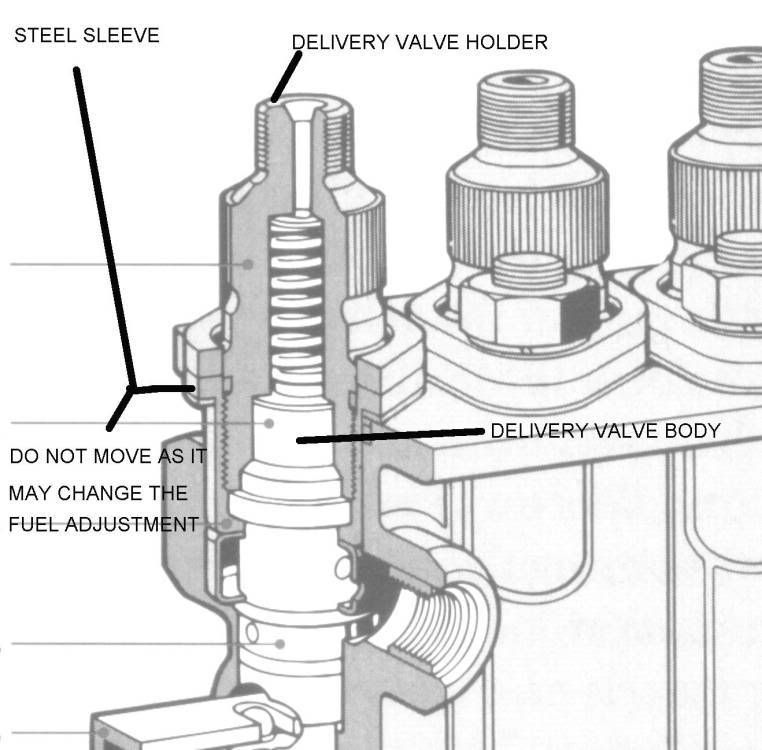

The adjusting nut is the Rack Damper Screw and it is adjusted while the Engine is completely warmed up and running at normal Idle Speed to smooth out the idle vibrations of the Engine. The Rack Damper is found only on Turbocharged Engines. When you adjust it you back it out until it has no effect on smoothing out the idle and slowly turn it into the IP until is starts to effect the smoothness of the idle. After that you need play with it turning it in and backing it out until you find the “sweet spot” where you get the smoothest idle. Still on Picture #1 There is a yes and no to removing the Governor cover. I believe some of the Governor springs push against that cover and the Cover Gasket effects the tension on those springs. If you remove the Cover and damage the Gasket and replace it with some gasket material from the Aut0 Parts Store it will not be the same thickness and will have some effect on the Governor spring tension. The Gaskets that come in the Bosch Rebuild Kits for the IP are not as soft as the Gasket Material from the Auto Parts store and will not compress as much and therefore not change the setting as much. So, if you must remove the Cover I would replace it with a Bosch Gasket and not a homemade one. Also the Factory Service Manual in the case of my 300D has some drawings of how the Governor works and you can see from the drawing what presses against the Rear Governor Cover. This might give you some idea as to what might get messed up if your remove the cover. Picture #3 As you said do not loosen the 2 nuts on each side of the Delivery Valve Holder as the adjustment needs to be done on a test stand. As for the middle Delivery Valve Holder where the Fuel Injector Hard Lines screw into there is no need to go into them do any cleaning. On that model of IP the Delivery Valve Holder and Delivery Valve Body are sealed with a Crush Washer and there is no O-ring to go bad and leak. If you are just curious to see what is in there I would remove the #1 Delivery Valve Holder. This is the one you would have to take off any way to remove the Delivery Valve Spring when you Flow Time the IP to the Engine. Picture #4 Yes there is some electronic timing devices that can be hooked up by removing the big Plug and there is also a locking pin device that will lock the IP Camshaft in the “begin injection” position. Picture #5 Yes, you can remove the bottom pan from the IP; you should be able to inspect the condition of the Camshaft Lobes from there. There is a big O-ring used to seal the bottom pan. If it was me removing it I would clean the O-ring and pan with Brake Cleaner, let it dry and carefully coat with some Silicone Sealant before I put it back on. There is not much oil pressure in that area of the IP. This pic is not exactly like yours but used for some referance.  The Camshaft Begin Injection Locking Pin

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#5

|

|||

|

|||

|

Thats alot of great information!!

What is generally the problem with an older pump? What normally goes out first? On my current old engine, I find that I need to go half way down on the accelerator pedal to start in the cold. If I lift my foot after it starts, it stalls out. It has to warm up some before I can take my foot off. Is there an adjustment I can make to fix that? Jim |

|

#6

|

||||

|

||||

|

With the exception of leaking O-rings, O-rings that are not on the 84 300SD Fuel Injection Pump; they do not cause a problem. Rarely a bearing can go bad or something inside fatigues and comes loose; but rarely. (And if no one has been inside messing with the IP.)

But, the above is only true if Clean well Filtered Diesel Fuel and Lube Oil go through it through out the life of the IP. I would look elsewhere for the problem you describe. and leave the IP for last. I would pop off the throttle linkage down at the throttle lever on the IP. I then would try having someone else (with out pressing on the accelerator pedal) start your car while you I manipulate the lever. Doing this bypasses all of that throttle linkage. If it runs OK you have a problem somewhere in the linkage back to the accelerator pedal. If none of the above helps you might want to start a different thread with problem in post #5. My next thought is that next to you Steering Wheel Lock and by your Ignigion Switch is a Vaccum Switch/Valve that sends Vaccum to your Vacuum Shutoff on the IP. If this leaks it could send vacuum to the Shutoff at the wrong time. I would disconnect the Vacuum Hose at the Vaccum Shutoff and plug the hose and see if this changes anything. With the hose off you Vacuum Shutoff should not work at all and not interfere with acceleration or starting. For a similar reason I would disconnect the EGR Vaccum Hose and plug the hose to see if it is opening at the wrong time. If none of the above helps the Camshaft timing and IP timing need to be checked as well as a the Valve Clearances. With all of the above I am assuming there is not Air Leaks in your Fuel System. I found my Car would idle sligntly rough cold and improve when hot. I found that my Fuel Inlet hose down by the plastic Primary Filter could be easily turned by had around the nipple. Evidently the hose would not leak as much air when it was warm. Replacing the hoses cured that problem.

__________________

84 300D, 82 Volvo 244Gl Diesel Last edited by Diesel911; 01-05-2009 at 05:29 PM. |

|

#7

|

|||

|

|||

|

Thanks I will look into that. Runs pretty good when warmed up.

What lubricates all of the levers, etc at the end of the pump? oil or diesel |

|

#8

|

||||

|

||||

|

Quote:

An extra note: Not for your IP but on the Older IPs where the Oil is not comming from the Engine to lube it you put Oil in the IP separately.

__________________

84 300D, 82 Volvo 244Gl Diesel Last edited by Diesel911; 01-06-2009 at 02:09 AM. |

|

#9

|

||||

|

||||

|

Quote:

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#10

|

|||

|

|||

|

The old engine has 240000 miles and is in my 84 300sd. The "new" engine is the one I am currently rebuilding to eventually replace it.

|

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|