|

|

|

|

|

|

|

|

|

|

|

#16

|

||||

|

||||

|

JEBalles & Alastair,

My original degree is in Chemical Engineering (I have even put a copy of my primary degree on a post on here previously). I have worked for both Exxon & Dow Chemical and have many years experience in various areas of Chemical Engineering including polymer chemistry. JE, as a student I suggest that you go and talk to some one at your college who is experienced in polymer chemistry. The presence of double bonds in such molecules provides the necessary sites for polymerization, maybe if you go and have a look at a final year college chemistry text book you will see a diagram of an ester & so understand. If you are studying Industrial Chemistry or something similar, when you graduate, get a job with Dow Chemical, go look up their polymer research reports from the early 1980's & you will find out what I am talking about. They are not public released reports. If you are interested in bio-diesel production, its a very basic simple process, not at all technically complicated, many schools do it as part of science. Have a look at; http://www.goshen.edu/chemistry/Home/biodiesel/The_GC_Biodiesel_Processor Good Luck !! Alistair, When some one refers to liquids as "incompressible" , it highlights that person has only a very basic education in fluid mechanics. Most trade qualified people are taught that fluids are incompressible. Its only when some one studies fluid mechanics at a much senior (university) level they understand its not the case. I could refer you to many texts in fluid mechanics on this including,'Fluid Dynamics' by Daily & Harleman, it explains correctly why a fluid gets hot when compressed. The 'Handbook of Chemistry & Physics' & 'Chemical Engineers Handbook" have tables of compressibility factors for many liquids. One of the reasons for using Direct injection systems is to reduce the volume of diesel in the high pressure part of the system and so the effect of fluid compression. Some one may have 'got away' with running near pure ester fuel in their CDI motor. The conditions in the injectors of a CDI are very similar to those in high pressure reactors for manufacturing polymers, I have worked with a pilot plant doing exactly that, hence my comments. I can only conclude that the degree of polymerization has not progressed sufficiently to form products of sufficient molecular weight to cause problems in those specific cases. If you are a professional involved in large scale fuel production e.g. a refinery and have appropriate qualifications (Chemical Engineering or Industrial Chemistry Degree, not a 'lab rat') , one would expect that you would have an understanding of the importance of saturation of the fuel components to avoid polymerization. This is not something that a back yard bio-diesel maker could be expected to know about. I am sure that you are aware that many, possibly including yourself, like to tinker with things 'to get more out of them', all that is being done is to make changes and so reduce the level of redundancy and over design in things. Eventually some one goes too far and it fails. Just because 1 or 2 'get away' with doing something, it doesnt infer that it will always work. Doctors bury their mistakes, tinkerers and back yard mechanics tend to put them on the junk heap.

__________________

Grumpy Old Diesel Owners Club group I no longer question authority, I annoy authority. More effect, less effort....  1967 230-6 auto parts car. rust bucket. 1980 300D now parts car 800k miles 1984 300D 500k miles  1987 250td 160k miles English import  2001 jeep turbo diesel 130k miles  1998 jeep tdi ~ followed me home. Needs a turbo. 1968 Ford F750 truck. 6-354 diesel conversion. Other toys ~J.D.,Cat & GM ~ mainly earth moving |

|

#17

|

||||

|

||||

|

Polymerisation of Alkyl esters...

It is well known that alkyl-esters May polymerise...

However, very high pressures and temperatures are needed, Plus Lots of TIME... --In fact, Many Hours..... I think you'll agree that fuel in a diesel-system is only pressurised for some minutes at most before being either returned to tank or burned in combustion.... 'One Or Two Get away with'......? Nah, Hundreds of Thousands of guys here in Europe 'get away with' for many hundreds of thousands of miles.... --We have had CR systems common-place on the roads here for over 10 years! Citroen and Peugeot in Europe and UK warrant the use of 30% BioDiesel in their Brand-New cars as well as other makers, and Mercedes-Benz warrant the use of up to 100% BioDiesel in their Commercial Vehicles--Inc. those with a CR system... Go figure!

__________________

http://i190.photobucket.com/albums/z...0TDnoplate.jpg Alastair AKA H.C.II South Wales, U.K. based member W123, 1985 300TD Wagon, 256K, -Most recent M.B. purchase, Cost-a-plenty, Gulps BioDiesel extravagantly, and I love it like an old dog.  W114, 1975 280E Custard Yellow, -Great above decks  needs chassis welding--Really will do it this year.... needs chassis welding--Really will do it this year....

|

|

#18

|

|||

|

|||

|

Quote:

__________________

1987 300D 180k 1985 300SD 330k Helga 1992 300D Lola 269k- Sold 1986 325 coupe Bessie >300k Original engine(ODO Broke) sold 2006 2500HD Druamax Linda- Tows boat and looks pretty in garage thats about it

|

|

#19

|

||||

|

||||

|

Good to hear that you have now changed your view from "MYTH" to it may happen !!

With the addition of appropriate retardants to the ester it is possible to slow the reaction down. this is done in normal resin production at low pressures, hence your comment about hours. With pressures in excess of 15,000psi and temperatures in excess of 100F residence times in plug flow reactors are typically measured in seconds. The reaction may only produce moderate chain length molecules, they then combust much slower, and are likely to end up as a varnish in the combustion chamber. The retardant type is critical so as not to slow the combustion of the fuel. The use of Ammonia as a combustion catalyst in latest Mercedes diesels may help. I am unaware of any test results. Every one should note that Mercedes does not recommend the use of straight ester fuel. I believe that this stance is supported by the manufacture/designer of the injection system. Blends may help flush the cavities of the injector clean. It only took a handful of Toyotas to generate a recall of many. Alistair , do you add suitable retardants/stabilizers to the bio-diesel you produce? Have you undertaken properly designed blind tests on the effect of straight ester fuel in CRD motors? Having a few mates talk of their success is great, there have been plenty of problems with fuel in diesel motors that isnt straight hydrocarbon. I hope you have plenty of product liability insurance for the bio-diesel you sell if you are promoting its use in unblended form in a CRD.

__________________

Grumpy Old Diesel Owners Club group I no longer question authority, I annoy authority. More effect, less effort....  1967 230-6 auto parts car. rust bucket. 1980 300D now parts car 800k miles 1984 300D 500k miles  1987 250td 160k miles English import  2001 jeep turbo diesel 130k miles  1998 jeep tdi ~ followed me home. Needs a turbo. 1968 Ford F750 truck. 6-354 diesel conversion. Other toys ~J.D.,Cat & GM ~ mainly earth moving |

|

#20

|

||||

|

||||

|

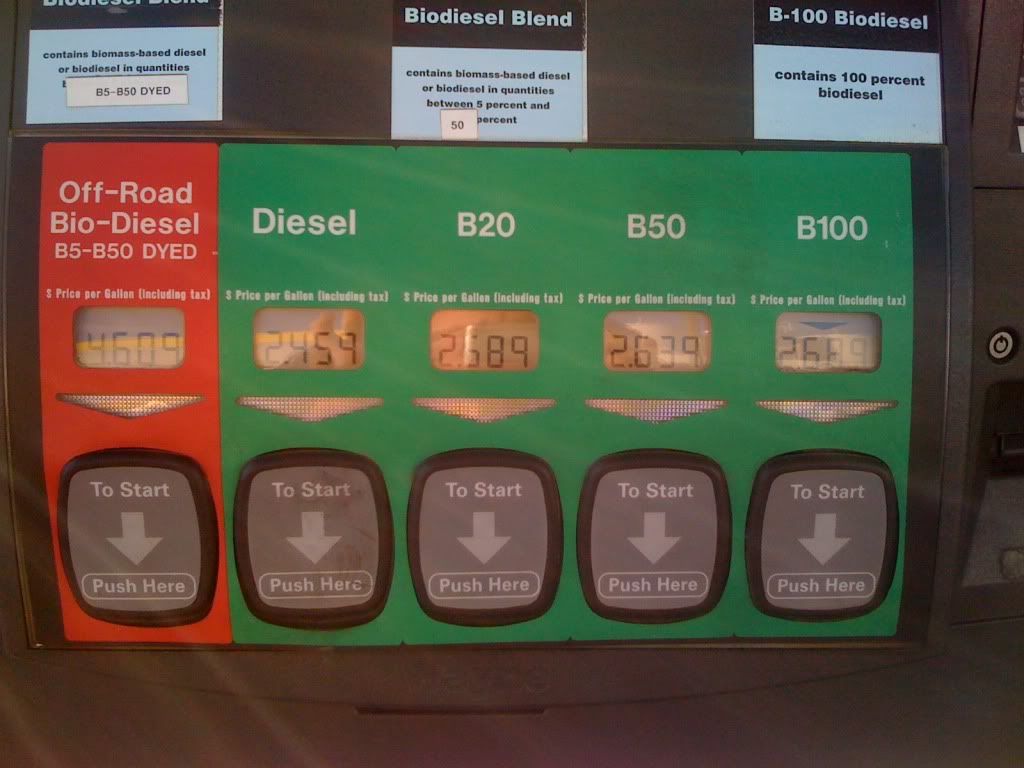

heh, off topic, but does anybody understand why the dyed untaxed fuel is twice the price of the taxed undyed fuel?

|

|

#21

|

||||

|

||||

|

Quote:

Before the customary, "Yeah, but that's not home made biodiesel..." this is just an example, and by no means at all the only example. This is not my video but it is a good one. **One product, among others, that can be made from biodiesel under the correct temps and pressures is epoxy.** I think you'd agree nobody wants that in a fuel system! These ARE my pictures of inside injectors from an OM617 with 'home brew' fuel not made correctly. -copyright Hessian American Imports  The photo labeled 'compare' is a 110,000 mile nozzle and disk from a car run only on conventional diesel fuel and one with less than 60,000 on home made fuel and some WVO. The photo labeled '3' is what came out of the fuel feed passage AFTER TWO HOURS in cleaning solvent followed by TWO HOURS in an ultrasonic cleaner. I used an air hose and the brown 'goo' came out the consistency of pancake syrup.

__________________

1987 300D (230,000 mi on a #14 head-watching the temp gauge and keeping the ghost in the machine) Raleigh NC - Home of deep fried sushi! Last edited by C Sean Watts; 04-16-2010 at 10:44 AM. |

|

#22

|

||||

|

||||

|

Quote:

That's Covering-Their-Behind. That doesn't necessarily mean it will not work - but what it does tell me is that it's probably on the edge and they dont want to take chances. There's no motivation for them to take chances on it either. Not enough customers are demanding to know, and it's not affecting sales drastically. If I was in there shoes I would NEVER says CDI is approved for anything other than petro-diesel. The B5 is tossed in there because that may become law eventually (or already is) in some markets. I guarantee that somewhere in Germany at Bosch or Mercedes or VW, someone has done extensive testing with on-spec B100 (and blends) on an engine test rig and torn down the engine to see what happened. They need to know what it looks like.

__________________

------------------------------- '85 300D, 'Lance',250k, ... winter beater (100k on franken-Frybrid 3 Valve Kit) '82 300D, 'Tex', 228k body / 170k engine ... summer car '83 300TD Cali Wagon 210k, wife's car |

|

#23

|

||||

|

||||

|

BINGO! No doubt about that. BUT the key - you said it - "ON SPEC B100." ASTM rated can possibly be made at home, but it's often far from any 'spec.'

__________________

1987 300D (230,000 mi on a #14 head-watching the temp gauge and keeping the ghost in the machine) Raleigh NC - Home of deep fried sushi! |

|

#24

|

|||

|

|||

|

Quote:

__________________

1987 300D 180k 1985 300SD 330k Helga 1992 300D Lola 269k- Sold 1986 325 coupe Bessie >300k Original engine(ODO Broke) sold 2006 2500HD Druamax Linda- Tows boat and looks pretty in garage thats about it

|

|

#25

|

||||

|

||||

|

Quote:

__________________

1983 240D 3.0T 4-speed manual, now sold  1989 Subaru GL Wagon 5-speed Touring Edition |

|

#26

|

||||

|

||||

|

On page one (first post of this thread) he mentions RUG. I thought I knew most of the terminology but what is that?

Thanks!

__________________

1991 300D 2.5 turbo 1991 560 SEL 1987 911 Toyota landcruiser Atlanta, Gawga |

|

#27

|

||||

|

||||

|

Quote:

__________________

-Typos courtesy of my mobile phone. |

|

#28

|

||||

|

||||

|

JE,

You will see from my location, I am in Australia. I obtained my original degree in Chemical Engineering from The University of Adelaide in the 1970's. I was a Registered Engineer in the State of Texas when I was working there in the 1980's. Hey Adam, I was going to quote you from a previous thread. How about running a CRD on peanut shells and what was the other secret fuel you mentioned??

__________________

Grumpy Old Diesel Owners Club group I no longer question authority, I annoy authority. More effect, less effort....  1967 230-6 auto parts car. rust bucket. 1980 300D now parts car 800k miles 1984 300D 500k miles  1987 250td 160k miles English import  2001 jeep turbo diesel 130k miles  1998 jeep tdi ~ followed me home. Needs a turbo. 1968 Ford F750 truck. 6-354 diesel conversion. Other toys ~J.D.,Cat & GM ~ mainly earth moving |

|

#29

|

||||

|

||||

|

Very often, what people make at home is not entirely biodiesel. It may burn, run in the engine and save you few dollars but for the average home brewer, quality control is lacking. It is easy to do but it is far from a foolproof process and there are many ways the finished product can fall short of ASTM standards.

__________________

1987 300D (230,000 mi on a #14 head-watching the temp gauge and keeping the ghost in the machine) Raleigh NC - Home of deep fried sushi! |

|

#30

|

||||

|

||||

|

Bio-diesel production is a much simpler process to some of the processes that occur in a refinery or petrochemical plant. How ever for the average Joe, its probably more complicated than any project he is ever likely to try.

Chemical processes like this are like cooking in a five star restaurant, you dont see a master chef starting with stuff out of a dumpster when they are making some prize winning meal. When you are using WVO as a starting material, its a case of c##p in = c##p out !! Unless you know exactly what is in your starting material, you dont know what else has been dumped into it, how much thermal cracking or rancidity has occurred. Good bio-diesel recipes have many steps to try and clean up the WVO so that the finished product ends up being of reasonable quality. The waste generated and energy used in the process is substantial when it is done properly. Its human nature to try & take short cuts. Problem is often you cant see if something is there, its at a molecular level. Just because its a nice color or smells nice, doesnt mean its any good. Its a bit like coloring the chunks in dog food. The dog cant tell the difference! Its color blind. A sound background in Organic Chemistry is more important than an adventurous or gun-ho attitude. I see those who would say "the Engineers are just covering their ass", that is true, we all know about "rod benders" and a few bridges that have fallen down. It then becomes the Engineers fault. One of the members on here has an appropriate quote in there sig "If it was easy, every one would be doing it"

__________________

Grumpy Old Diesel Owners Club group I no longer question authority, I annoy authority. More effect, less effort....  1967 230-6 auto parts car. rust bucket. 1980 300D now parts car 800k miles 1984 300D 500k miles  1987 250td 160k miles English import  2001 jeep turbo diesel 130k miles  1998 jeep tdi ~ followed me home. Needs a turbo. 1968 Ford F750 truck. 6-354 diesel conversion. Other toys ~J.D.,Cat & GM ~ mainly earth moving |

|

| Bookmarks |

|

|