|

|

|

|

|

|

|

|

|

|

|

#16

|

|||

|

|||

|

The spedo needle is operated by a spinning magnet in a cup at the rear of the assembly.

The shaft the needle attaches to, is attached to a floating cup, and the magnet spins inside the cup. there is a shaft attached to the magnet that the cable drives. Charlie

__________________

there were three HP ratings on the OM616... 1) Not much power 2) Even less power 3) Not nearly enough power!! 240D w/auto Anyone that thinks a 240D is slow drives too fast. 80 240D Naturally Exasperated, 4-Spd 388k DD 150mph spedo 3:58 Diff We are advised to NOT judge ALL Muslims by the actions of a few lunatics, but we are encouraged to judge ALL gun owners by the actions of a few lunatics. Funny how that works |

|

#17

|

|||

|

|||

|

Quote:

1) Tranny spins inner cable. 2) Inner cable w/ square end spools up a magnetic cylinder (or at least a cylinder w/ a magnet on one end or some sort of magnet at an eccentric location on one end). This cylinder rests in the brass sleeve. 3) The magnet on the end of the cylinder is magnetically coupled to another cylinder or wafer of some sort. That cylinder/wafer gets rotated and is connected to a shaft. The shaft moves the needle. 4) A spring counteracts the force of the magnetic coupling and returns it to zero. If that's the set up, then different symptoms may be caused by different spots. Assuming a lubed cable with good fittings and a smooth curve, #1 shouldn't produce either noise or jumpiness. If not lubed, then probably noise, but probably not jumpiness since it should be spinning more/less consistently and not stop/start. If the fittings are stripped or improperly engaged at either end, then anything goes. #2 could produce noise if the cylinder/fitting (cup) has friction, but shouldn't produce jumpiness on the needle. Unless the square end isn't engaged properly, then noise and jumpiness. #3 might produce both, but probably more to do with jumpiness. There has to be some sort of bearing for the needle-connection-shaft. If the grease or lube on that bearing is old, then it may stick. #4 shouldn't affect much of anything, unless the spring breaks or in an esoteric "work hardening" becomes stiffer with age. Sound about right? Anybody have any dissection pics? |

|

#18

|

|||

|

|||

|

I have a somewhat similar problem...ie jumping needle under 20mph. The strange thing about mine is sometimes the needle sits on the peg until i hit 30mph or so. I've heard the sticking pin theory but i've already tried different "sheaths" over the pin....same result. I'm stumped as to why it sticks.

|

|

#19

|

||||

|

||||

|

You REALLY need to watch the cable routing and its angle, how tight you make the screw-down of the cable to the speedometer, and to a smaller extent, the angle of the actual gauge assembly.

While I had found at first that lubing the piece on the speedometer helped, I still got bouncing after the cable settled into a new position. The optimal position for the cable is not how it lays from the factory, at least on my car. I need to have it a little bit tighter and higher up to be right. Lubing definitely helped as there is no more binding noise, which I was getting (minus the screeching from the old one) even on the new cable. Ive been playing with mine over a few months and probably 1000 miles of driving, and Im only getting close now to an optimal alignment for minimal bounce at very low speed and no bounce at high speeds so the cruise control doesnt surge and works right.

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (116k) 1991 350SD (206k) 1991 300D (228k) 2008 ML320 CDI (199k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (267k) Past Diesels: 1983 300D (228K), 1985 300D (233K), 1993 300D 2.5T (338k), 1993 300SD (291k) |

|

#20

|

|||

|

|||

|

Quote:

The rotating magnet induces an EMF due to Lenz's law which may be thought of as a subset of Le Châtelier's principle. The EMF generate eddy currents in a current loop. The moving electrons create a magnetic field, a B field. The magnetic field induces a torque on an element attached to the shaft holding the pointer. The rotational spring counters the torque. The needle position is proportional to the rate of rotation. Ignore at your leisure. Just one of those silly things I learned a long time ago that stuck in my brain. |

|

#21

|

|||

|

|||

|

1982 300SD speedometer quit

The speedometer needle suddenly dropped to zero, from 65 yesterday morning (6 degrees out). Since then it has been un responsive. I confirmed the connection at the back of the cluster, and it is connected as it always has been. The needle has never "bounced" or howled / screamed, as many report. Any ideas? I have not checked the other end, as I am not sure where it connects to the transmission, and frankly it is just too cold to crawl under there for a non essential element....3000 rpm = 65 mph in my car.

Any ideas or recommendations? |

|

#22

|

||||

|

||||

|

That stinks. I'm going to guess that a brittle cable just snapped or sheared. Could also be that if the speedometer somehow bound, it caused the cable to twist and break.

I doubt that it fell out of the trans, it's in there pretty good. Seems easy enough to fix on either end, and you can get a new cable from fastlane.

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (116k) 1991 350SD (206k) 1991 300D (228k) 2008 ML320 CDI (199k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (267k) Past Diesels: 1983 300D (228K), 1985 300D (233K), 1993 300D 2.5T (338k), 1993 300SD (291k) |

|

#23

|

||||

|

||||

|

I believe you can disconnect the cable housing at the speedo and pull out the cable within. I suspect its broken and a short piece will come out.

__________________

81 300CD (sold) 1972 280 SEL 4.5 (sold) 1966 250 S 4 spd (sold) 1974 450 SL (sold) 86 BMW 325ES (sold), 1973 280C (sold) 1988 300 SE. |

|

#24

|

||||

|

||||

|

Finally solved. Posted this elsewhere but figured it might be better served here for archiving.

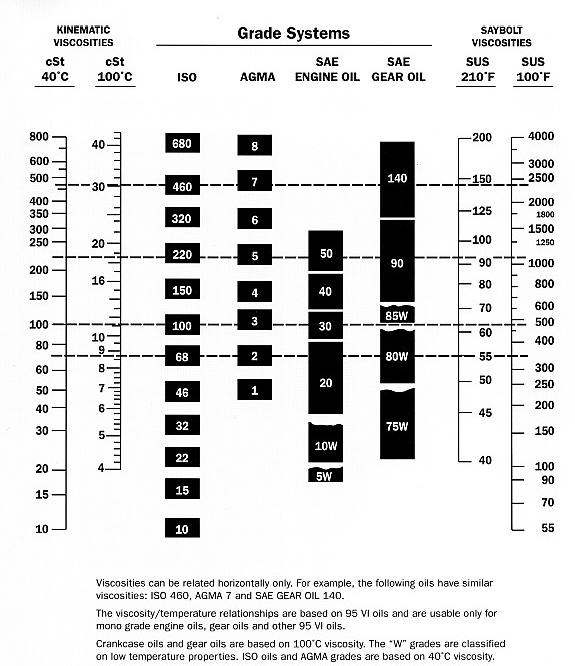

So, after looking at zoom spout oilers, which generally have ISO 100 or ISO 68 non detergent oil in them, I thought it would be good if something a bit lighter was used. After all, this thing has to spin without viscous drag in conditions below freezing. I found that Slip2000 EWL is a lot less viscous, as it’s around 20cSt at 40C, versus... 68 or 100cSt.  This: https://www.slip2000.com/slip2000_ewl.php Data: https://www.slip2000.com/downloads/herguthlabs2.pdf Applied it to the outer side of the bushing:  And the inner side:  I also used some dorman graphite in the cable tube, it flowed right in.  This stuff: https://shop.advanceautoparts.com/p/dorman-help-graphite-cable-lubricant-03344/11245160-P More solvent than oil. Not sure it was necessary or what... Now it’s as smooth as any mechanical speedometer that I’ve seen, with just a very slight bounce/wobble below 10 mph, which is very minor compared to before (maybe 1-2mph of wobble at up to 5 or so MPH, after that smooth as can be).

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (116k) 1991 350SD (206k) 1991 300D (228k) 2008 ML320 CDI (199k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (267k) Past Diesels: 1983 300D (228K), 1985 300D (233K), 1993 300D 2.5T (338k), 1993 300SD (291k) |

|

| Bookmarks |

|

|