|

|

|

|

|

|

|

|

|

|

|

#16

|

|||

|

|||

|

Cam timing mark....

Quote:

It was helpful to me, whne I pulled my first head off, to also remove the vacuum pump. It does make things easier - it will try to yank on the timing chain at the worst possible times. Why are you replacing your head? Did the car run right to begin with? Anyway - stay motovated - hang in there. |

|

#17

|

|||

|

|||

|

Head gasket blew and I found an engine in the pick a part with a #22 head for $160. I figured why not replace my #14 with the better one if it's going to be all apart anyway. Oil was spraying all over the engine compartment and cooling system was pressurized when cold.

Are you saying that it doesn't matter which way I put the cam back, as long as it's 180 degrees? So even though the timing mark was at the bottom I can align it at the top because #1 is at top?

__________________

1987 300 SDL 2000 E320 Wagon |

|

#18

|

||||

|

||||

|

It very much matters how you put back the head because the IP is presently 180* out of phase. If you still have the head, put it back on and turn the crank to align the cam tower marks. No need to go through the full torque sequence, the first 2 steps are fine, but clean the bolt holes thoroughly. Use the old head gasket. I don't know that I'd want to guess what #6 TDC is on the cam and hope to keep the crank, cam and IP in time. The trouble is, how do you rotate the crank along with the IP without a head to keep the chain in tension?

Sixto 87 300D |

|

#19

|

|||

|

|||

|

I have 2 heads. One at the shop and the one I took off yesterday. How do I clean the bolt holes? I don't have a tap set.

__________________

1987 300 SDL 2000 E320 Wagon |

|

#20

|

|||

|

|||

|

Sorry I wan't clearer. I don't know how your cam ended up 180 out of phase, it definately should not be that way. What I meant was, as long as the crank and cam are both at TDC for the #1 cylinder, it does not matter if you are on the compression or exhaust stroke. just be really, really sure you don't move anything after the head is off.

As for cleaning out the head bolt threads; You don't need a tap follower tool. There is alot written in this forum about different ways to do this. I filled all of mine first with clean oil and let it soak, then I vacuumed it out with my shop vac, then filled with mineral spirits, inserted a q-tip and worked around all the threads, all the way to the bottom. Then (while closing my eyes and protecting the cylinders) blew it all out with a compressor. Some will wash, rinse and repeat several times. The point being, any metal in there can throw off the head bolt torque readings or worse, cause you to snap a bolt or damage the threads. Screaming deal on the #22 head - wish that would happen to me! Did your #14 head crack or have to gotten it checked? They are still good to have around and sometimes people will buy them as an emergency spare. |

|

#21

|

|||

|

|||

|

I haven't gotten it checked. On first glance it doesn't look cracked but it may be. Previous owner said it overheated so he replaced the fan clutch. It overheated on me twice and pegged the temp above 120c.

Head gasket looked blown 1-5 on the passenger side and 6 at the rear. To be clear and make sure I understand correctly, cam was pointing down because the engine has 2 tdc and it was on the btdc? Putting the head back on and the cam pointing down the way it was when I took it off, and rotating balancer another 360 degrees will bring both the motor and cam to tdc? Right now #1 and #6 are both at top. I

__________________

1987 300 SDL 2000 E320 Wagon |

|

#22

|

|||

|

|||

|

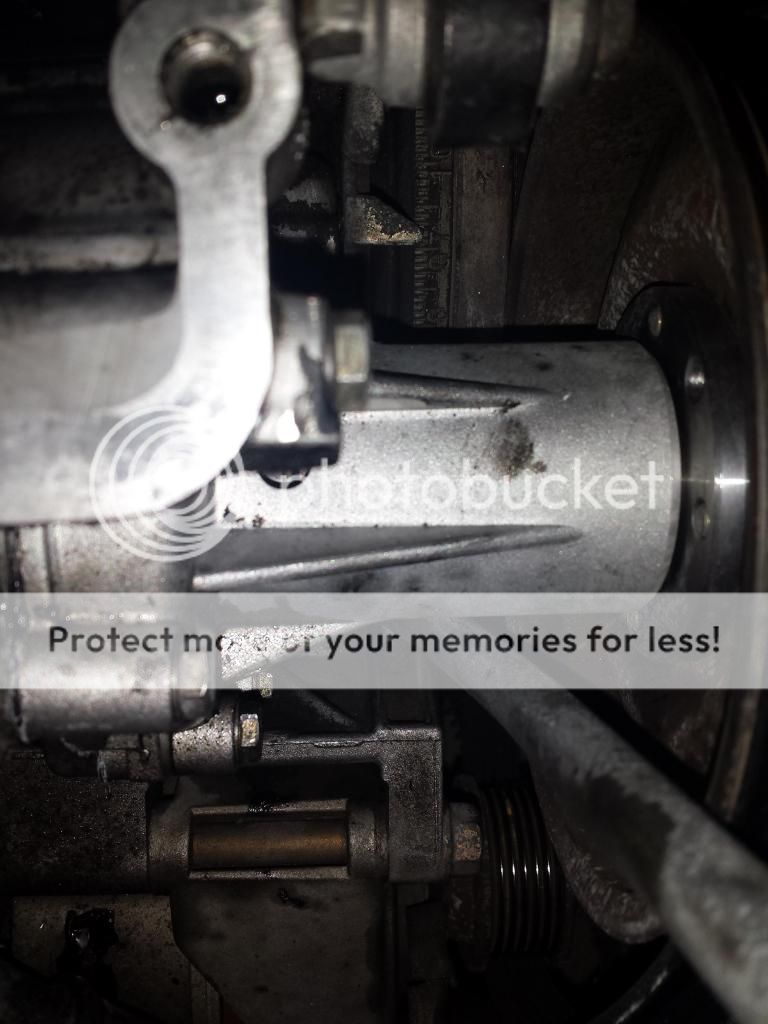

Look at the collar behind the sprocket, not the cam lobes...

Quote:

Now, there is only one TDC for an engine (that we care about for this job). There is no other. On the crank balancer there are numbers stamped and a pointer that guides you to TDC for the crank. Since you've already removed the head and I'm a little unsure of where everything was set before you started, I will ask this; where is the crank indicator pointing right now? It should be at 0 degrees (I believe the marking will be the letters TC for top center). Somewhere on this forum there is a great photo that shows the tic mark and exactly how it aligns with the cam towers, I just wish I could remember where it was. |

|

#23

|

|||

|

|||

|

It was on DT but must have moved a hair when removing head

__________________

1987 300 SDL 2000 E320 Wagon |

|

#24

|

|||

|

|||

|

Just went out to check both cams and the timing mark was pointing down. The pin for the cam gear was at 6'oclock and the timing mark is right next to it. Could it be that the previous owner had work on the head and the mechanic put the cam back wrong 180 degrees? Would the engine still run?

Here's a post I found showing the timing marks E300D timing chain stretch

__________________

1987 300 SDL 2000 E320 Wagon |

|

#25

|

||||

|

||||

|

It's actually 0 (zero) T. The balancer will read 0|T twice - once #1 ignition TDC, once at #6 ignition TDC. By coincidence, #6 is also at TDC at #1 ignition TDC and #1 is also at TDC at #6 ignition TDC. The problem with the cam not being at #1 TDC is that you might damage the cam if/when you remove the cam towers. There is a sequence for removing the cam towers which requires the cam to be at #1 TDC. The problem if you install the head at #1 TDC with the block as is is that the IP is out of phase. If the #14 head is still with you, put it back, put back the tensioner, and give the crank a full turn.

Sixto 87 300D |

|

#26

|

||||

|

||||

|

Quote:

You can't make an engine run with the cam *OR* IP out of phase. This has been said but I'll say it again - the crank turns twice for each turn of the cam; therefore, every other time the crank reads TDC the cam will be at #1 TDC (cam sprocket pin down, cam sprocket flange notch aligns with cam tower mark). Every other time, the cam will be at #6 TDC (cam sprocket pin down, cam sprocket flange notch does not align with cam tower mark). This has also been said because I said it - get the head back on and give the crank a full turn. Sixto 87 300D |

|

#27

|

|||

|

|||

|

I have 2 heads and thus 2 cams. I will put the 14 head back on and rotate the crank. I broke the slide rail and both pins are ****ty and can't be reused. Can this be done without the pins and rail? I've ordered new ones but no eta yet.

__________________

1987 300 SDL 2000 E320 Wagon |

|

#28

|

||||

|

||||

|

No upper guide rail is no problem for just one crank turn by hand.

Sixto 87 300D |

|

| Bookmarks |

|

|