|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

#1

|

||||

|

||||

|

OM603 engine swap, which belt to use? (Plus other interesting things)

So the other week by tensioner pulley decides to grenade itself on my way to work. The engine in the 350SDL came out of an 87 300D which already had 400,000 or so miles on it but with a new head. This was 6 years ago now and another 150,000+ miles as the 350SDL itself just turned 322,000. Doing the job was relatively straight forward from the DIY posted here.

I had to use some creativity to hold the water pump pulley because Harbor Freight F^&*ing sucks and didn't stock the pulley holder and couldn't send me one in the mail on time despite spending almost as much on shipping as on the damn tool. (FYI my much larger parts order from Pelican ALSO shipped out from California on the same day. They charged me NO shipping and got it to me ahead of schedule) Today was the one day off that I had in order to do this job and I couldn't wait any longer for the tool to come in....  I used the old belt which was pinched when the pulley came loose so I had no intention of using it again. In this photo above there was still slack but by putting a small plastic electrical relay under the belt just above the headlight bracket it gave me just enough force to undue the cooling fan without using the weight of the G to pull it tight.  After removing the older tensioner I put on a spare pulley that I had from my original engine and put on the new belt. I will mention at this point that the serpentine belt went on fairly easy but that I still needed to use a good amount of force to get it over the last pulley. When I checked the tension I found it to be acceptably tight. I also started the engine briefly without the cooling fan and again, everything seemed fine. Here is where things get frustrating though. While the above "Procedure" worked to remove the fan, I couldn't use it to tighten the fan. I had read that a few people have managed to hold the pulley by hand while tighting the bolt so I gave it a shot. I tried but was unable to hold the pulley and in my frustration I tried to hold the pulley by pushing down on the serpentine belt between the water pump and the power steering pump. What happened next is what has me perplexed and a bit worried. When I pushed down on the belt and tried to tighten the cooling fan I swear I could feel the belt stretch or otherwise become loose. Now the belt is definitely loose beyond acceptability and even occasionally chirps a little bit when revving it at idle. I won't be driving the car until that damn HF pulley holder comes in and I get this sorted. Is it even possible to stretch a slightly warm belt or even damage a pulley with was less then my full weight pushing on the belt? My only (Hopefully) saving grace is that I may have ordered the wrong belt. The engine swap from a W124 has always made buying certain parts rather....interesting (Do I get them for the 350SDL or the 300D/300SDL?) In this case I ordered the 2145mm serpentine belt which is supposed to fit the 300D/300SDL. The 350SDL used a 2120mm belt. While writing this post I went through my older receipts and did find a return of a 2145mm belt and a purchase of a 2120mm belt. Also I don't think it matters but I also swapped out the fuel pre-heater/thermostat which I think may have been letting air into the system. I will find out in the morning if it was... Any thoughts will be most welcome.

__________________

1982 300GD Carmine Red (DB3535) Cabriolet Parting Out 1990 300SEL Smoke Silver (Parting out) 1991 350SDL Blackberry Metallic (481) "The thing is Bob, its not that I'm lazy...its that I just don't care." |

|

#2

|

|||

|

|||

|

I just grab onto the fan pulley with some vise grips to hold er stady during re assembly.

__________________

Current fleet 2006 E320 CDI 1992 300D - 5speed manual swapped former members 1984 300D "Blues Mobile" 1978 300CD "El Toro" |

|

#3

|

||||

|

||||

|

I use the "channel lock pliers" or offset jaw slip adjustment pliers... they work great to hold the pulley.

are you sure you have the belt routed correctly? OM603 Serpentine Belt Routing

__________________

John HAUL AWAY, OR CRUSHED CARS!!! HELP ME keep the cars out of the crusher! A/C Thread "as I ride with my a/c on... I have fond memories of sweaty oily saturdays and spewing R12 into the air. THANKS for all you do! My drivers: 1987 190D 2.5Turbo 1987 560SL convertible 1987 190D 2.5-5SPEED!!!  1987 300TD 2005 Dodge Sprinter 2500 158"WB 1994GMC 2500 6.5Turbo truck... I had to put the ladder somewhere! |

|

#4

|

||||

|

||||

|

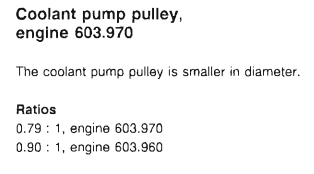

The different belt length is due to the larger 350SD/L water pump pulley. Do you know which one your car has?

If it has the original 3.0 water pump pulley use the belt for the 3.0  -J

__________________

1991 350SDL. 230,000 miles (new motor @ 150,000). Blown head gasket  Tesla Model 3. 205,000 miles. Been to 48 states! Past: A fleet of VW TDIs.... including a V10,a Dieselgate Passat, and 2 ECOdiesels. 2014 Cadillac ELR 2013 Fiat 500E. |

|

#5

|

|||

|

|||

|

Are you serious? They put a larger pulley (aka slower water pump) in the 350? Why would they do such a horrible thing?

__________________

CENSORED due to not family friendly words

|

|

#6

|

||||

|

||||

|

Oops, I was confused... it's a smaller pulley to make the fan go faster.

-J |

|

#7

|

|||

|

|||

|

OK that makes a lot more sense. I put a smaller M103 pulley on my 87 water pump to spin the pump faster but didn't change the belt length. Its good to know the .970 has a stock smaller pulley and belt. I'll keep an eye out for one of those.

Thanks!

__________________

CENSORED due to not family friendly words

|

|

#8

|

||||

|

||||

|

You know I honestly don't know

A mechanic did the engine swap for me and a few years later he also redid the front engine cover so i'm not sure which pump is from which engine. It does make sense that I installed the wrong belt (it would explain why I returned a 2145mm belt a long time ago) A mechanic did the engine swap for me and a few years later he also redid the front engine cover so i'm not sure which pump is from which engine. It does make sense that I installed the wrong belt (it would explain why I returned a 2145mm belt a long time ago)Fyi the pulley holder still hasn't arrived....9 days and counting....

__________________

1982 300GD Carmine Red (DB3535) Cabriolet Parting Out 1990 300SEL Smoke Silver (Parting out) 1991 350SDL Blackberry Metallic (481) "The thing is Bob, its not that I'm lazy...its that I just don't care." |

|

#9

|

|||

|

|||

|

Quick ebay search and I found the smaller pulley to swap onto my 87 603.

Short belt 2120mm goes with pulley #6032050110, 138mm diameter Fits: 602.911, 602.961, 602.962, 603.970, 603.971, 606.96 Long belt 2145mm goes with pulley #6032050210, 157mm diameter Fits: 602.983, 603.960, 603.961, 606.910, 606.91 It was 103f today, I want all the water pump speed I can get especially at idle. I've been driving around with the M103 pulley and 2145mm belt for too long.

__________________

CENSORED due to not family friendly words

Last edited by tjts1; 09-11-2014 at 03:50 AM. |

|

#10

|

||||

|

||||

|

Ok update with frustration.

The harbor freight pulley holder FINALLY came in and I managed to get around to replacing the belt today. The good news is that I was able to get the fan off and do the job in record time. Getting this smaller belt on was of course considerably harder as I had to undo a bolt on the alternator in order to get it into place but overall everything went smoothly. The bad news is that now there is a rough gurgling sound coming from the front of the engine but only at idle (Revving the engine even very slightly makes the noise go away) Furthermore I see a bit of wearing on the inside edge of the belt. I only ran the car for a few minutes. I should mention that it also made this noise when the larger belt was on which I thought was the source of the noise but now I know that this isn't the case. I do notice that the belt seems to be too far "in" on the idler pulley. I moved it out as far as possible by hand and the noise went away at first but them came back as the belt shifted back to the location shown below. I am sure that the belt it routed correctly and every grove was flush with every pulley. When I reinstalled the front tensioner I used the old tensionor but with a used pulley. (As such everything, washer and all, went it just like it was before)) What am I missing here?

__________________

1982 300GD Carmine Red (DB3535) Cabriolet Parting Out 1990 300SEL Smoke Silver (Parting out) 1991 350SDL Blackberry Metallic (481) "The thing is Bob, its not that I'm lazy...its that I just don't care." |

|

#11

|

|||

|

|||

|

It looks like ur using the short belt with the large pulley. You're probably at the limit of the tensioner travel. The short belt with the correct size WP pulley shouldn't take any more tension or disassembly.

__________________

CENSORED due to not family friendly words

|

|

#12

|

||||

|

||||

|

Quote:

An interesting theory but it wouldn't explain why the longer (2145mm) belt was far too loose. (To the point where it would squeak) |

|

#13

|

|||

|

|||

|

Check the pulleys and tensioner. Short belt with large pulley is not a solution. That belt looks frayed.

__________________

CENSORED due to not family friendly words

|

|

#14

|

||||

|

||||

|

Quote:

1. Way back in 2004 we swapped out the 350SDL engine for an 87 300D engine. The problem is that a shop did the install so i'm not 100% sure about which engines ancillaries they used. I do know that I still have a bin full of 350SDL engine parts. 2. Everything with the swap seemed to go smoothly until about a year into the "new" engine. The day of my interview at a Land Rover dealership in 2005 I start the car to depart for home and I heard a small chirp/squeak from the belt when I started the car. It was very brief so I didn't think much of it. On the way home upon taking a sharp right hand turn I heard a noise and the dashboard lit up. The belt was gone and the tensioner had failed, putting a hole in the front engine cover. 3. I brought the car to the same shop which did the engine swap and brought them the spare front engine cover which I still had from the 350SDL. 4. Again all seemed fine accept for a small oil leak. However it was that this point that I started to see my belts shred and fail about once every year and a half. (I replaced at least two of them) We couldn't figure out what was going on until I had to replace my radiator. With everything off of the front of the car we were finally able to see that the alternator pulley was almost 1/4 of an inch shorter then the rest of the pulleys. We shimmed the alternator pulley and now it lines up perfectly. I have not lost a single belt since doing this job almost 5 years ago. 5. Somewhere in all of that I replaced the tensioner hydraulic which went bad (I may have even done this twice, but I don't remember) 6. A few weeks ago the tensioner pulley itself falls apart again after taking a right hand turn. When I replaced the pulley I reused the tensioner arm which was already on the engine but I used the pulley from a spare arm that I had in the box of 350SDL parts (There were some small detail differences between them and everything else prior to loosing the pulley was fine so I didn't want to mess something up even further) The spare tensioner arm has a part number of 601 202 06 28. What I do not know at this point is which tensioner arm is which, (350SDL or 300D) I did a search of the part number but didn't come up with anything.

__________________

1982 300GD Carmine Red (DB3535) Cabriolet Parting Out 1990 300SEL Smoke Silver (Parting out) 1991 350SDL Blackberry Metallic (481) "The thing is Bob, its not that I'm lazy...its that I just don't care." |

|

#15

|

||||

|

||||

|

Ok I was finally able to get around to this job again (4 days off from work last week and of course it rains every fricken day

!) !) I've recently been expanding my tool collection and I want to get way more scientific and precise when it come to my repairs so for the first order of business I bought myself a decent digital caliper. (Shown below) My first discovery was to measure and verify that I do indeed have the 138mm water pump pulley so at least I know that i'm using the correct belt (2120mm)  From there I went about removing the tensioner arm again only this time going through it much more carefully. Well low and behold I think I found something! When I took the tensioner arm apart the first time I did notice a bit of "edging" on the arm but I didn't think anything of it. Well on this inspection I realized that the large washer is bent & ovaled in the center! Looks like the washer and arm may have been damaged when the pulley went. (This certainly explains the gurgling/rattling sound that I was suddenly getting at idle!) I'm not 100% sure that it explains the belt fraying so i'm proceeding cautiously.   I still have the other tensioner with part number 601 202 06 28 but it will be useless without a new washer (I don't think it's the washer-less version but I could be wrong) Annoyingly I found a spare washer in my parts bin that was exactly the same size as the old one but it's made out of aluminum (The original is steel)

__________________

1982 300GD Carmine Red (DB3535) Cabriolet Parting Out 1990 300SEL Smoke Silver (Parting out) 1991 350SDL Blackberry Metallic (481) "The thing is Bob, its not that I'm lazy...its that I just don't care." |

|

| Bookmarks |

|

|