|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

Fixed 1982 300SD odometer slip at high speed

Ok, so I've been posting here and there on the forum that my silly odometer "slips" at high speeds. It seems to click off miles okay while I'm going under 60mph but when I hit 75 it is clearly slipping.

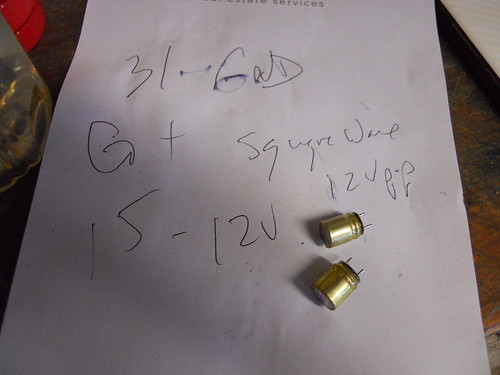

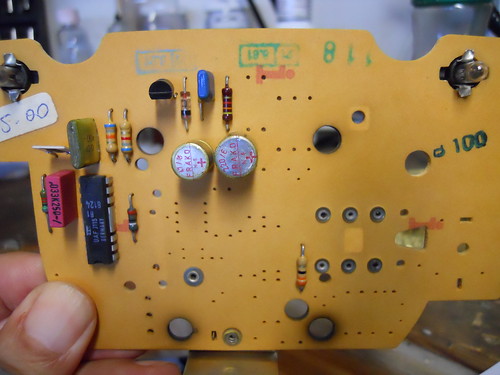

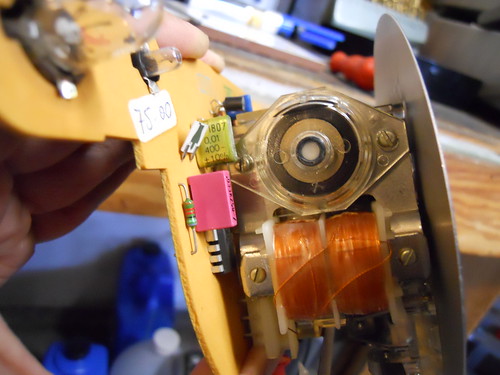

I was getting really mad because my MPG is all messed up. I checked my odometer with an iphone app and it is 20% off. It dang near stalls when I hit 75mph so the error must be crazy high on long trips. I got frustrated because my highway mpg is lower than my around town. So I finally solved my problem. A lot of folks wouldn't notice this. But I calculate mpg and something just didn't make sense. I've known for awhile it slipped at high speeds after seeing my trip from San Francisco to LA was only 200 miles. Go figure. Lots of high speed. Around town it acts normal. This is sad because I thought this was a low mile 300SD when I bought it. It prolly has way more than the OD says. I even checked to see if it spun when I bought it ten years ago and clearly it clicked off miles...but not accurately. So I set about to fix it for good this week. First I installed the garagistic gear set. When I opened the thing it had rotten gears. Soft and crumbly. Cogs all over the place. I was sure I'd solved the skipping problem. I was missing a tooth here and there and I figured that was it. Put in the gears, no problem. Drove the car. The odometer stopped making so much noise and it clicked off miles. I was pretty happy till I hit 75 mph on the highway and it just stopped. I backed off to 60 and it started clicking off tenths again. ARRRRGGGHH!!! So I took it apart again. I found a JamesDean post with the electronic pinouts for the unit so I could drive it on the bench. This is the electromechanical deal and it cannot be driven with a drill. You need a signal generator and a twelve volt power supply. The board is clearly marked G+ is speedo signal which I set at 5 V p-p sine wave 100 to 200 Hz. 15 which is 12V in. 31 which is ground. Once I got it up and running I swept the frequency and the speedo needle went from 0 to 80mph smoothly. No problem. But I could clearly see that the odometer was not reliably clicking off tenths from 60 to 80mph. It got worse as I sped it up. It wasn't really slipping. It was skipping. As if it was missing a pulse. So I changed the caps.   This did nothing for the skipping. I put in some good tantalum replacements I had lying around. I looked up the data sheet for the speedometer chip that drives the odometer motor on the little board. ITT UAF0115. I found data on a similar UAF2115. The caps are simply power supply decoupling caps. Yeah, if they are bad it will mess things up but apparently that wasn't my issue.  I checked out the electrical signals coming from the chip that drives the motor using an o-scope. They were ugly pulses but they were all there. They appear to be a clock type signal...one pulse to advance the mechanism and another to hold it in place. The motor seemed to have two phase coils to acheive this. pulse - hold - pulse - hold. I think. Anyhow signals looked okay. No skips. But I could audibly hear missing clicks. The gear train in the odometer looked all herky jerkey. Something was still wrong. Something mechanical. So I started pressing my finger on the drive shaft between the odometer motor and the drive pinion. When I loaded it with some friction it seemed to behave. Less skipping and the noise became regular. I noticed the magnet in the motor had a heck of a lot of end play. So I decided to put a little o-ring in with a dab of silicone grease in the little end cap. Little o-ring  endcap  Works real well now. Reminds me of the cigarrette butt fix for the tachometer amp. I'm not sure if it is the friction or positioning the magnet on the extreme end of the excitation coils but hey, it no longer skips. Hope this helps somebody. I really have wondered about this thing for years. I think I've finally licked it. Well, it works on the bench. Checked the odometer with a stopwatch and it matches the needle at 80mph. I'll check using the iPhone odometer app and get back.

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles 97 C280 147k miles Last edited by ykobayashi; 06-05-2017 at 07:29 PM. |

|

#2

|

|||

|

|||

|

Very nice.

__________________

85SD 240K & stopped counting painted, putting bac together. 84SD 180,000. sold to a neighbor and member here but I forget his handle. The 84 is much improved from when I had it. 85TD beginning to repair to DD status. Lots of stuff to do. |

|

#3

|

||||

|

||||

|

Wow. Where do you guys get all this expertise?

|

|

#4

|

||||

|

||||

|

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles 97 C280 147k miles |

|

#5

|

||||

|

||||

|

Update.

So a year after I did this fix my odometer started slipping again. It works fine up to 40mph and at 55 mph and over it slips a bit. I can tell because at 60mph you should be reading one mile in one minute, or the tenths on the trip odometer should click off every second. I took it apart tonight and put it on my signal generator to simulate some speed on the speed sensor input. Same problem came back. There was too much play in the main stepper motor shaft like I shimmed above with that little o-ring. After tinkering around with it I found that the best way to get it reliably clicking off miles without slipping was to add two more o-rings of the same size on the motor shaft but on the opposite side of the shaft right behind the tiny pinion. This pinion. Same o-rings as above. Two on the shaft right behind the pinion to shim the gap. The rattling has quieted down and it is reliably clicking off miles on the bench without slipping. So that’s on my signal generator. I’ll try it out on the road tomorrow.

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles 97 C280 147k miles |

|

#6

|

|||

|

|||

|

Quote:

On the subject of these 126 speedos, are you able to say if the odometer motor driver chip is also involved in driving the speedometer galvanometer? If so, does the chip contain the information that allows the same basic speedo package to operate with a variety of "K" values? Examples: a car with a 3.46 final drive and two reluctor lobes on the trans output shaft will have a speedo with a "K" value of 5686, whereas a car with a 2.47 final drive and four reluctor lobes will have a "K" value of 8075. Can different "K" values be accommodated with changes to other board components, or is it all in the chip? |

|

#7

|

||||

|

||||

|

Yes I think so. Just doing a cursory search for the part mentioned above UAF2115 there is a galvanometer output pin. There is also a pin called “divider ratio” which is likely set by a resistor network. That may be the thing you’re looking for to calibrate the speedometer. Also there is an RC time constant set on another pin…these often set frequencies. I can see on the board above that the pink capacitor and green resistor are precision components. They may set the pulse input to galvanometer output ratio…perhaps.

Gotta read the UAF2115 data sheet. I think you’re on the right track though in that the speedometer needle deflection is not controlled by a gear tooth count. It is set electronically. Looks like the Porsche people play with this circuit a bit. There are some posts at the Pelican parts forum about modding it. Looking at the https://www.radioradar.net/en/datasheets_search/U/A/F/UAF2115_ITT.pdf.html I think the RC network (green resistor and pink cap) are what sets the duty cycle of the input to the galvanometer drive. This ultimately sets the current flowing to the speedometer needle. So if you want to change the speedometer cal I would look at changing the resistor value slightly. Without looking at the data my guess is the RC time constant trips a threshold like in a 555 circuit and sets a pulse width. The longer the time constant the wider the pulse. Just a guess. So increasing the resistor value may make the needle deflect more at the same speed. Easiest is to pull a speedometer. Put it on a signal generator. Make a plot of input frequency vs. speed stock. Then pull the little green resistor. Measure it. Replace it with a pot or a known resistor that is smaller or bigger. Make another plot of frequency vs. speed on the gauge. Figure out the relationship and that will help you decide which resistance will be appropriate for your ratio. Maybe another approach is to just try to pick resistances that hold,the speed at a constant like 55mph and then you determine the frequency resistance relationship. I’ve never recalibrated a car for a diff swap or wheel swap. I figure the proper way is to go from wheel circumference to diff ratio to K value and you get a resistor that you drop in to get the correct speed. I would be very tempted to just put a potentiometer on that little spot for the green resistor and go driving with a gps and turn the knob till I got the speed I wanted. Then replace the pot with a precision low temperature coefficient fixed resistor. ETA - forgot to mention. Drove on the highway yesterday and the odometer works properly. No slipping. For now.

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles 97 C280 147k miles Last edited by ykobayashi; 06-10-2022 at 09:48 AM. |

|

| Bookmarks |

|

|