|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

Jammed ignition lock - steering column mechanism worn

ATTENTION-I AM STILL WORKING ON THIS. DO NOT TRY THIS YET. READ TILL END TO GET LATEST UPDATE. YOU CAN POTENTIALLY JAM YOUR LOCK USING MY TIPS. I AM STILL FIGURING THIS OUT.

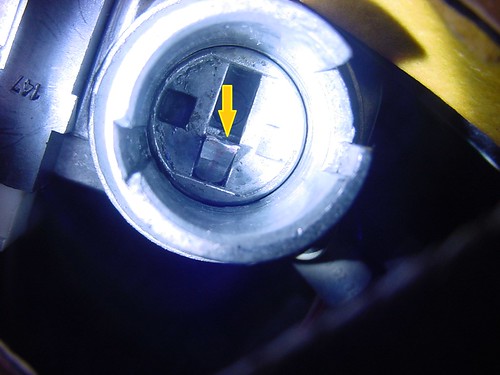

Hey All, So my 82 300SD started to get the dreaded jamming ignition key. I can still turn it if I jiggle it. I got home and decided to take it apart. I had the same problem on my 240D many years ago. And I know, our favorite Mercedes Diesel entrepreneur has YouTube videos about "change your lock core or else" but in my experience of two cars it never was the lock core. It was a worn interlock in the steering column lock. Replacing the core is for the most part a waste of time but it makes some money for the guy who sell videos and cores. It ain't the core. My key and cylinder are perfect. At the bottom of the lock behind the key is a little ramp shaped button that needs to be depressed or the steering column lock mechanism won't rotate. I discovered this thing years ago when I removed the lock cylinder on my 240D and tried to use a screwdriver and it wouldn't turn. You need to depress this ramp thing in the bottom of the lock tube and move it to the side. It's an extra interlock to make the car harder to steal. Shown here. Core is out. I'm looking down the tube. Some really creative designer put this entire design together. They didn't want the system to be easily defeated. The column lock.  The ramp button to be hit by the key tip. Made of stainless steel. Lasts a long time...40 years in my case. Maybe this is an argument for using brass key blanks instead of the original steel ones.  See the wear? That little piece is supposed to be flat. If the key doesn't press that worn spot down enough the lock doesn't turn. If you cannot turn the lock, you cannot easily remove it to service it.  Now with my 240D I just went out and bought a new column lock. I contemplated TIG welding some stainless steel to the divot and shaping it with a file but I couldn't figure out how to take the entire assembly apart. It's kind of peened together. But now, I'm finding I cannot just go out and order one of these at Pelican...or elsewhere. There are some entrepreneurs selling them on ebay. But I don't want a used one or an overpriced new one. I considered pinning it like people have done here. That is becoming more likely. Also maybe I should tear it down and try welding some material to it. Another idea was JB welding some thin shimstock to the divot. I haven't made up my mind yet. I don't feel like getting my argon tank filled just for this (I haven't welded in years) and I don't think I can braze to the stainless with a propane torch. And glue is not durable enough. Since this is going to become an ongoing problem now that the part is NLA I'd like to come up with a robust solution. This is what I've done in the meantime. I'd still like to use my car so I 3D printed a plastic replica of the black metal barrel. This way if it decides to jam up on me I can remove the barrel with a hot knife (cigarette lighter and swiss army knife if I am stuck someplace). Then I can start the car at least with a screwdriver. I'll post this file up on Thingiverse if anyone is interested. It is a oddball solution and not a very good one but if you would like to play with it, have at it. It's a short term solution.    The situation with NLA just gets worse everyday. This issue isn't going away and we'll all have to deal with it one way or another eventually. I'm actually going to try to come up with a better solution to cheaply fix mine. I'm thinking of using the shimstock off a floppy disk to make a little "cap" to glue down like a tooth crown. Or maybe I'll weld. Stay tuned.

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles 97 C280 147k miles Last edited by ykobayashi; 04-15-2022 at 12:05 PM. |

| Bookmarks |

|

|