|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

Jammed ignition lock - steering column mechanism worn

ATTENTION-I AM STILL WORKING ON THIS. DO NOT TRY THIS YET. READ TILL END TO GET LATEST UPDATE. YOU CAN POTENTIALLY JAM YOUR LOCK USING MY TIPS. I AM STILL FIGURING THIS OUT.

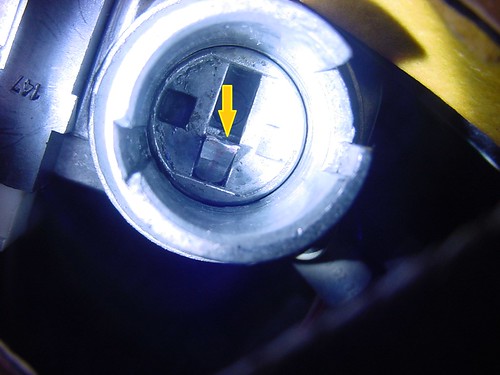

Hey All, So my 82 300SD started to get the dreaded jamming ignition key. I can still turn it if I jiggle it. I got home and decided to take it apart. I had the same problem on my 240D many years ago. And I know, our favorite Mercedes Diesel entrepreneur has YouTube videos about "change your lock core or else" but in my experience of two cars it never was the lock core. It was a worn interlock in the steering column lock. Replacing the core is for the most part a waste of time but it makes some money for the guy who sell videos and cores. It ain't the core. My key and cylinder are perfect. At the bottom of the lock behind the key is a little ramp shaped button that needs to be depressed or the steering column lock mechanism won't rotate. I discovered this thing years ago when I removed the lock cylinder on my 240D and tried to use a screwdriver and it wouldn't turn. You need to depress this ramp thing in the bottom of the lock tube and move it to the side. It's an extra interlock to make the car harder to steal. Shown here. Core is out. I'm looking down the tube. Some really creative designer put this entire design together. They didn't want the system to be easily defeated. The column lock.  The ramp button to be hit by the key tip. Made of stainless steel. Lasts a long time...40 years in my case. Maybe this is an argument for using brass key blanks instead of the original steel ones.  See the wear? That little piece is supposed to be flat. If the key doesn't press that worn spot down enough the lock doesn't turn. If you cannot turn the lock, you cannot easily remove it to service it.  Now with my 240D I just went out and bought a new column lock. I contemplated TIG welding some stainless steel to the divot and shaping it with a file but I couldn't figure out how to take the entire assembly apart. It's kind of peened together. But now, I'm finding I cannot just go out and order one of these at Pelican...or elsewhere. There are some entrepreneurs selling them on ebay. But I don't want a used one or an overpriced new one. I considered pinning it like people have done here. That is becoming more likely. Also maybe I should tear it down and try welding some material to it. Another idea was JB welding some thin shimstock to the divot. I haven't made up my mind yet. I don't feel like getting my argon tank filled just for this (I haven't welded in years) and I don't think I can braze to the stainless with a propane torch. And glue is not durable enough. Since this is going to become an ongoing problem now that the part is NLA I'd like to come up with a robust solution. This is what I've done in the meantime. I'd still like to use my car so I 3D printed a plastic replica of the black metal barrel. This way if it decides to jam up on me I can remove the barrel with a hot knife (cigarette lighter and swiss army knife if I am stuck someplace). Then I can start the car at least with a screwdriver. I'll post this file up on Thingiverse if anyone is interested. It is a oddball solution and not a very good one but if you would like to play with it, have at it. It's a short term solution.    The situation with NLA just gets worse everyday. This issue isn't going away and we'll all have to deal with it one way or another eventually. I'm actually going to try to come up with a better solution to cheaply fix mine. I'm thinking of using the shimstock off a floppy disk to make a little "cap" to glue down like a tooth crown. Or maybe I'll weld. Stay tuned.

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles Last edited by ykobayashi; 04-15-2022 at 12:05 PM. |

|

#2

|

|||

|

|||

|

PM sent

__________________

"Rudeness is a weak man's imitation of strength" - Eric Hoffer |

|

#3

|

||||

|

||||

|

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles |

|

#4

|

|||

|

|||

|

Just recently finished fighting this same issue. My tumbler was perfect (key SS and somewhat worn, though). The tab in the column lock assembly you refer to was worn just like you show. I hadn't put it all together that that wear would be the issue.

Looking at the unit with the assembly removed, I could not figure out why the key assembly would turn everything perfectly (while the key always remained in) but if I took the key out and reinserted it, I had to jimmy the locking pin inwards before the key would go back to flawless operation. The tab you talk about must be what pulls the same lock in...? And with the tab worn, the key doesn't have enough oomph to pull everything in together by itself. My dirty solution was to drill and tap two holes 180* apart in the locking pin side. I screwed two screws into it against the lock (which was slightly depressed inwards) and cut them flush. I then JB Welded the bottom end to "lock" it all into place. Reason I didn't put one screw all the way through the assembly was I wanted the assembly/steering column alignment button to still work. With the lock depressed fully inwards at its furthest travel, the alignment button no longer "popped" back out. Allowing the steering lock to travel slightly out (still within the confines of the entire assembly) I regained the alignment button functionality. I could have figured this out ahead of time and still drilled and tapped a through bolt but I was too hasty as well as wanting my hole to be deep enough inwards to not "peel" away the aluminum from the end. |

|

#5

|

||||

|

||||

|

Yeah I’ve been thinking about that little worn tab. It’s kind of a side bar mechanism that prevents the cylinder from turning unless the key tip pushes it aside. Just another level of security.

Why? My best guess is to stop people from A) picking the lock using classical picking. Even if you hit all the tumblers the lock won’t turn if you don’t depress the little tab at the end of the lock. B) it stops people from putting a big screwdriver in the lock cylinder and forcing it with a wrench. It’s an additional latch to shear off besides the tumblers. It may be thick. And that brings me to my next idea. I am going to pull the steering lock tomorrow and try to pull it out. I saw this YouTube video and Pierre Hedary just taps the steering lock on the table and this piece pops out. Maybe it comes out easily after the electrical switch is removed? Or there’s an E-clip? Anyway I’m going in. I’ve mentally comitted myself to getting to the bottom of this. I want mine fixed and I’m ready to fire up my welder to make it good as new. Or better, remove that pesky little interlock. MB diesels are kind of thief repellent already. Pierre Hedary video. Not the biggest fan of his video style but he does something very interesting at 3:50. https://youtu.be/A-gfWvhCOGQ

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles Last edited by ykobayashi; 04-20-2022 at 07:30 PM. |

|

#6

|

||||

|

||||

|

Progress! Here it is. A visual feast because we are visual creatures.

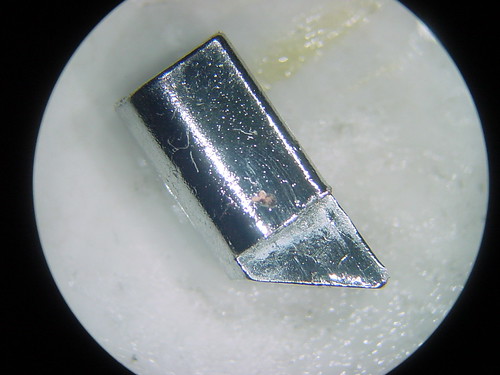

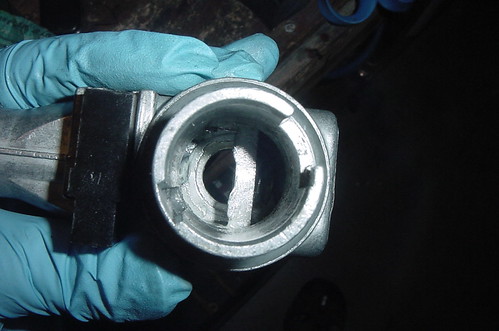

So I decided to drop my column down, take off the lower dash, remove the instrument cluster and remove the lock assembly. It's out and here is what I've found. This is for an 82 300 SD. Not sure if W123 is the same. Got the unit out on the bench.   Separate the switch. Three screws on the connector panel on the back.  Now you can see the cam and vacuum shutoff switch in the back. Pull the vacuum switch and blue cam off.  Now just tap out the middle section from the cam side and that whole button ramp interlock release section drops out the front side.  The center pops right out. Here it is with the mating section of the lock tumbler. You can see how the tip of the key pokes through on the right and hits the little ramp button and pushes it aside which moves the bolt out of the bore of the lock. This allows the lock to turn. Its kind of like a lock sidebar in a GM car. If you torque the tumbler and try to pick it, this bolt will bind up. I think.  Pops apart like a little puzzle. Now we can see our little worn tooth that is springloaded to the locking bolt. This is definitely an additional lock to prevent torque attacks.  This is the worn part. Pull it out of the locking bolt body. Watch out for the little spring. You can see how worn the little tip is. It is worn in exactly the indentation of my key. On close observation I realized that this isn't stainless steel. Wouldn't that be nice? It's chrome plated red bronze. A good material. Non magnetic so I thought it was stainless but on microscopy it is bronze.    It isn't worn much but it is deformed and smashed as well as indented. 40 years of starts. You can see the bronze under the indentation from the key. I flattened out the indentation a bit with a file. I hammered it back into square. Roughed it up good and prepared to cap it. I made a template out of paper for a little cap made of shim stock. I got the shimstock off an old floppy 3.5" disk I had floating around. They have nice stainless shimstock on the little sliding door. I cut it out, formed it, then JB welded it to the little wedge. Will it hold? I think so. This thing isn't under a terrible amound of stress. It just moves that triangular bolt out of the way a smidge to get it out of the way. There is the light spring backing it up so I don't think the JB weld will see much stress. Mostly the steel shim stock will take abrasion wear from the key.    oh yeah and I found this cracking. I tried to close it up and get some JB weld in there.  Final shot of the shim stock "cap" glued down. It's like a dental cap. I know this stuff because my grandfather was a dentist. I didn't know him but it's in my DNA.   So how's that? I will get this thing back together and give an update on its performance. My luck it'll fall apart and jam up my ignition in a bad neighborhood. This is one possible approach. The cracks on the potmetal may mean that rebuilding has limits. This entire hobby is showing limits for that matter. This is another example of how we are all going to have to adapt to NLA parts. This is not the hobby it was ten years ago. On a brighter note I'm wondering if there's a way to mass produce that little nose. I don't know much about casting. Did some jewelry in a shop class as a kid. I think this can be investment cast in large quantities in my garage. Maybe from a 3D printed positive or wax positive? I have a 3 axis cnc. Maybe I should take some measurements before I put it back together. Rebuilding isn't that hard after you get it out of the car. The cracked potmetal is another issue. Maybe I should have brazed some brass on to it and ground it down. Now I'm second guessing my approach. I didn't want to go down and get shield gas. I probably could have done it with Bernzomatic brazing rod and MAP gas. Hmm. Maybe I was too hasty to go for the JB weld. Well, there's always next time. I think I'll be using that plastic tumbler collar for awhile in case this doesn't go well. ETA - you know just leaving this little latch out maybe a good solution. The lock wouldn’t jam. It would be less secure against a torque attack or a picking attack. But the column lock would still function. You just wouldn’t have the deadbolt action when this little interlock latches up. And you wouldn’t have to worry about that piece of metal getting worn out by the key. Graphically I mean leaving this entire part out. The bolt and the little button.

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles Last edited by ykobayashi; 04-15-2022 at 07:12 AM. |

|

#7

|

|||

|

|||

|

Wow, that is an impressive bit of fiddling!

|

|

#8

|

|||

|

|||

|

"wow", indeed. Extremely impressive! Very nice write up and the pictures are outstanding. My hat's off to you, sir! If I have this problem, I'd probably opt to just remove the worn out little ramp. I'd loose a bit of security, as you mentioned, but mine isn't a "cream puff" (pretty low on the "hot" list for theft, I'd imagine). When I first got my '83 240D, a few years ago, the key jammed and wouldn't turn. I was able to eventually remove it and replaced the tumbler. Good, so far. Didn't know about this cause, at the time, and maybe that's all it was? Might have to go back "in there" and check it out. Got the "2 key" thing goin now, which doesn't bother me. I did save the original tumbler. Thanks for the extra effort! Really great info.

|

|

#9

|

||||

|

||||

|

Ok I just posted an edit in red on the first post. Do not try this yet. The verdict isn’t in. I’ve just assembled my lock twice and JAMMED the key in it twice. Luckily I was able to get the tumbler out by pressing on the square release key with a c clamp. I further disassembled the lock.

Done by tapping the lock bolt end with a ball peen. It knocks the door off on the other side. This thing is tricky inside. I do not really understand it…yet. We are not done so read for entertainment but do not try any of my stupid stuff before I am sure I’m not going to jam up everyone’s locks. Inside there is a block on the end of the bolt. It has a square hole in it. All the surfaces are worn. The problem is more than I thought. There is wear and slip everywhere inside and the square hole is supposed to cam the bolt into dead locked states and gliding states depending on the angle of the key. I either put my lock back together wrong or I added too much material. Bottom line it’s really messed up. I’m debating on gutting all the innards and just keeping the housing and switch. BTW - to get it apart to this point you need to take out the center rotor then tap the lock bolt tip with a hammer. The door flys right off along with a couple of springs.

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles |

|

#10

|

|||

|

|||

|

I seem to recall the development of this theft proof lock cost some 8 million at the time? It should be hard to understand!

__________________

92 e300d2.5t 01 e320 05 cdi 85 chev c10 |

|

#11

|

|||

|

|||

|

Quote:

It also goes a long way to help me understand why I love my beat up '83 240D more and more, every single time I drive it! I can only imagine what it'd be like to drive a really nice, low mileage example in pristine condition. Not sure what the price range was for a new W123 in the early 80's, but I'd venture to say it was a bargain at 2 or 3 times the asking. Nothing could even come close in build quality, engineering, safety, etc. in those days, for that amount of money. |

|

#12

|

||||

|

||||

|

I ended up gutting the column lock. It’s back together. The electrical switch is out…not sure what that one does but maybe it won’t buzz if I leave my key in the ignition.

It is really smooth now. The detents are still there. What I found out is my little metal repair to that wedge was hanging up. There was too much overhang on the sloped edge and that apparently is important because the key glides over it during part of the tumbler’s rotation. The wedge button pushes this angular bolt into the corners of a square that jams up the column lock intentionally. But somehow my little mod wasn’t letting it release. I think I need to build up some brass on that little casting and grind it again. It’s amazing how a little metal there makes such a big difference. The precision of this thing must have been pretty high when it was new. For another week.

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles Last edited by ykobayashi; 04-15-2022 at 02:55 PM. |

|

#13

|

||||

|

||||

|

Does it look like something you could file out of a piece of key stock? The boy's 300SD is beginning to have issues with the key not turning and if it's just that little part, I'd happily sit at a vise with a bunch of jeweler's files to make a new one.

Brass key stock is available at McMaster. Michael

__________________

Usta haves '69 250/8, '76 280C, 1971 250C 114.023, 1976 450SEL 116.033 Current have, 1983 300SD 126.120 |

|

#14

|

||||

|

||||

|

It won't help or add much but I will short story my experience. I had what appeared to be a lock tumbler issue. It turned out to be my Steering Colum Lock was broken in 2 places.

I rendered the locking plunger useless. And installed the new Steering Colum lock. A little more than a year later my lock tumbler fell apar internally. So, in fact it can indeed be the lock tumbler. However, I have been a member since 2007 and it seems like there was a phase were frequently the lock tumblers caused the stuck key issue. As that phase past a few years later it seems like the cause was Steering Colum Locks wearing out or breaking.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#15

|

||||

|

||||

|

I am contemplating getting a big brass bolt at home depot and milling this shape out on my mill. In the meantime I gutted the steering lock. Easy to do. First take out that center barrel behind the key tumbler. Then tap on the bolt tip to get the guts to fly out the little door on the side. The peens are weak so it just comes apart with some tapping. Mind all the little parts and the two springs that drop out.

Empty the bore:  Tap here:  Insides pop out the little door side. Watch out for the two springs. I put this piece back in.  Mind the orientation of this piece relative to the tumbler. It can go in two ways. Make sure to check it against the vacuum cam blue thing to make sure it switches the vacuum switch as you turn the key to the on position. I left out the bolt, the door, the internal square cam body and some springs. Basically I just turned the keyway into a locking electrical switch. More later as I repair that little pawl. I am either going to make another out of brass with a mill and files like Michael suggested or I will braze some brass to the surface and grind it back into shape.

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles |

|

| Bookmarks |

|

|