|

|

|

|

|

|

|

|

|

|

|

#91

|

|||

|

|||

|

EGR test kit

Brian, Installed the kit today on 603 engine. Only problem was aligning bolt with nut in clamp as you described. Found ovalizing the proximal hole in clamp with rat tail file made it easy. Thanks again for offering this nice kit to us.

|

|

#92

|

|||

|

|||

|

Mike,

Glad the kit worked out. Getting that bolt started is a royal PIA and it will cross thread quite easily. I never ovalized mine but I did spend a good 30 minutes with the 617 to get it started. The 617 is much more difficult than the 603 due to the increased stiffness of the clamp. If anybody is struggling with it, send me an e-mail for additional support. |

|

#93

|

||||

|

||||

|

I must appoligize. I keep forgetting to arrange to get some $$ out to you for a kit.

__________________

"Know other lessons I need to learn? TELL me. Tired of learning'em the hard way". Glow Plug Wait: [i} Time of silence in homage Rudolph Diesel. Longer you own a diesel. more honor you give". [/i] Life; SNAFU Situation Normal All Fouled Up, & FUBAR: Fouled Up Beyond All Repair -Now: Snafued Jeep TJ w/OM617 2Be daily driver & building SS M1079 w/Ambo boxed /live in Adv. Truck, Diesel KLR conversion -Sold 62 UNIMOG Camper w/617 Turbo, 85 300SD |

|

#94

|

|||

|

|||

|

Not a problem George. Just one more day that you have to look at that butt ugly valve sitting there...............

|

|

#95

|

||||

|

||||

|

Sorry, I havent sent the money, but Im listed as wanting one long ago. I have been travelling so much, I havent been on here as much as I'd like.

I have one issue though. When I pull the valve, there is a set of vacuum tubes that need to be plugged: the piggyback valve on the valve cover, and the two connections on the engine, that go fom the piggyback valve to the engine (temp sensor?) and the second going from the engine to the EGR. What would I use to seal all those off? I have tried searching and posted in another thread, and never found much good info. The best I saw was to drive a screw into the hole for the connection on the valve cover. Maybe this would work, but Id like a better solution to go with the nice setup I'll be getting. Thanks, JMH

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (116k) 1991 350SD (206k) 1991 300D (228k) 2008 ML320 CDI (199k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (267k) Past Diesels: 1983 300D (228K), 1985 300D (233K), 1993 300D 2.5T (338k), 1993 300SD (291k) |

|

#96

|

|||

|

|||

|

You only need to plug one port.

You can plug the hose, right at the valve. Or you can remove the hose from the valve to the coolant sensor and plug the coolant sensor with a rubber cap. Or, you can remove the hose from the coolant sensor to the piggyback valve on the valve cover and plug the piggyback valve. Or you can the remove the vacuum supply to the piggyback valve on the valve cover and cap the vacuum supply with a rubber cap. The last suggestion would leave you with the cleanest setup. Since there is no vacuum downstream of the capped port, you can remove all the vacuum hoses and not worry about the open ports. |

|

#97

|

||||

|

||||

|

Brian,

Thanks for the shipment of the EGR "test" kit. Installed mine this morning and it went very smoothly. Trying to determine what a "good amount" of sealant made me ponder for a moment yet after reading the tube I decided 1/8" plus due to using it on both mating surfaces should work. Locked it up and put the keys where my two sons won't grab them and start it up prior to the 24 hours. Thanks again.

__________________

Steve '87 300TD - 132K - Soon 4-Sale '84 300D Turbo - 122K - Driving '77 VW Type II - 77K - Restored '08 250EX Ninja English Bulldog (Brier) - My best friend. Passed away 12/02/04 while in my arms. |

|

#98

|

|||

|

|||

|

Steve,

I want everybody to use a lot of sealant, because the process of putting on the clamp causes most of the sealant to squeeze out. This is due to all of the moving around that the plate undergoes when you are trying to get the clamp to start. If you use too little sealant and it does not fill the gap between the plate and the manifold, it is going to leak. Glad it worked for you. |

|

#99

|

||||

|

||||

|

Brian,

Good point to get out here, especially after I read my post. The 1/8" plus was heavy on the "plus" and it does flow out. I'll let you know after 24-hours if I detect any leaks but I certainly doubt it. Thanks again.

__________________

Steve '87 300TD - 132K - Soon 4-Sale '84 300D Turbo - 122K - Driving '77 VW Type II - 77K - Restored '08 250EX Ninja English Bulldog (Brier) - My best friend. Passed away 12/02/04 while in my arms. |

|

#100

|

||||

|

||||

|

Brian,

As you probably expected, mine worked just great. No leaks. Thanks.

__________________

Steve '87 300TD - 132K - Soon 4-Sale '84 300D Turbo - 122K - Driving '77 VW Type II - 77K - Restored '08 250EX Ninja English Bulldog (Brier) - My best friend. Passed away 12/02/04 while in my arms. |

|

#101

|

|||

|

|||

|

Quote:

|

|

#102

|

||||

|

||||

|

Quote:

Did you receive my $$$$$$$$$$$$$$$

__________________

Enough about me, how are you doing? |

|

#103

|

||||

|

||||

|

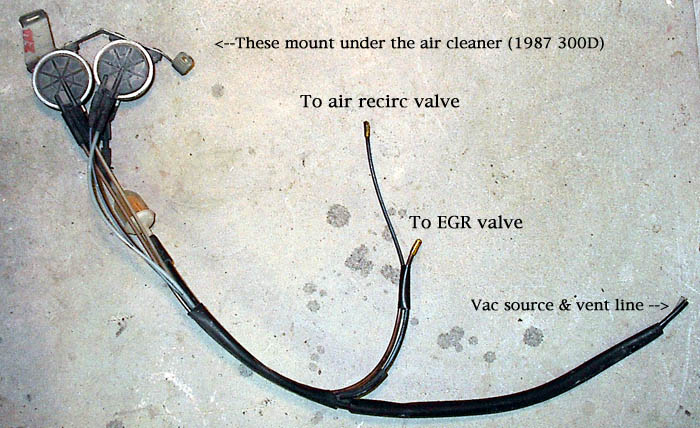

Cleanest setup (1987 300D, W124.133)

Last edited by gsxr; 01-01-2009 at 07:55 PM. |

|

#104

|

|||

|

|||

|

Quote:

|

|

#105

|

|||

|

|||

|

Quote:

I did, and your kit is rolling down I-95 somewhere in the middle of North Carolina, if I had to guess.

|

|

| Bookmarks |

|

|