|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

Tighten fan belt 90 2.6 190E

It is the weirdest thing. I cant get the belt to fit on my car. Ya, I know...look at threads...no really. I replaced the fan clutch bearing bracket and now the belt wont go back on. The tensioner either wont go slack enough of the belt shrunk. I have the belt diagram and I know how to tighten the belt tensioner. I just cant figure out what I am missing that is keeping the belt from fitting over the pulleys.

__________________

Christopher Henkel 1990 190E 2.6 - Arctic white SOLD 1986 190E-16v - Blauswartze 1993 300CE - SOLD 2003 W208 CLK 320 Cabriolet - Magma Red |

|

#2

|

||||

|

||||

|

If you loosened your tensioner and the belt won't go on, re-check the belt routing to be sure you have it on right.

__________________

1993 190E 2.3 2001 SLK230 1971 LS5 (454) Corvette Convertible |

|

#3

|

|||

|

|||

|

It could be that you have not loosened the tensioner.

You should seriously consider leaving the tensioner alone and taking the alternator loose, putting the belt on and replacing the alternator.

__________________

2012 E350 2006 Callaway SC560 |

|

#4

|

|||

|

|||

|

The damper shock will extend the tensioner all the way out with the bolt loose. Loop the belt around everything but the water pump and PULL on the belt toward the driver's side fender. The shock will slowly collapse and allow you to fit the belt on.

Too late now, but did you notice where the pointer on the tensioner itself was when it was tight and where it was when loose? If it didn't return to the start of the "ramp" cast in the tensioner body, you need to replace the tensioner, the rubber is shot and you won't be able to get it tight again. Peter

__________________

1972 220D ?? miles 1988 300E 200,012 1987 300D Turbo killed 9/25/07, 275,000 miles 1985 Volvo 740 GLE Turobodiesel 218,000 1972 280 SE 4.5 165, 000 - It runs! |

|

#5

|

||||

|

||||

|

Quote:

I replaced the compressor, expansion valve, and drier on my 190 2.3 last week, and when I loosened the tensioner the pointer went half way. Sure enough, the rubber tensioner was shot. Installed a new one and hopefully this will be the last one... if I can get my wife to part with the car.

__________________

1993 190E 2.3 2001 SLK230 1971 LS5 (454) Corvette Convertible |

|

#6

|

||||

|

||||

|

thanks for the help

I checked the belt routing with the actual cars manual. It should be correct.

The belt is a MB belt, it should be the correct length and size. I have changed th belt before on a few diff 190e cars. The tensioner is loose. The tensioner will move from side to side, back and forth. What I cant get to happen is the belt to go on over all the pulleys. I dont know why. If the tensioner rubber is bad with that keep the adjuster nut from tightening? I put the belt on the way i thought was correct and it was way too loose and i could not get the tensioner to tighten up to take ouut the slack. I then checked the manual and saw they had a different routing for the belt. I rerouted the belt and the belt is not long enough to go on the pulleys in the route shown in the manual. I am stumped.

__________________

Christopher Henkel 1990 190E 2.6 - Arctic white SOLD 1986 190E-16v - Blauswartze 1993 300CE - SOLD 2003 W208 CLK 320 Cabriolet - Magma Red |

|

#7

|

||||

|

||||

|

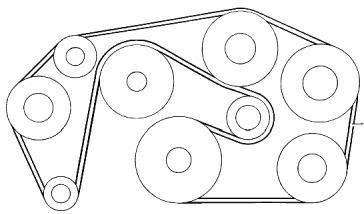

OK, I'm looking at the 2.6 belt routing and just like on my 2.3, you want to put the belt in place, then do the water pump pulley last. As you can see in the belt diagram, when you pull up on the belt to put it on the last pulley, the tensioner will move to allow enough slack to get the belt on.

You stated that the tensioner is moving freely, so, check and re-check the belt routing, and try pulling up on the belt to put it on the water pump pulley last. BTW, is this the same belt you removed before you replaced the fan clutch bearing bracket?

__________________

1993 190E 2.3 2001 SLK230 1971 LS5 (454) Corvette Convertible Last edited by slk230red; 06-23-2007 at 01:26 PM. |

|

#8

|

|||

|

|||

|

Belt routing is hard to screw up, although it can be done. If I remember correctly, there is only one place you can goof up, and that is which side of the crank pulley you put the loop for the tensioner on. It goes between the crank pulley and the fan pulley -- put the belt over the tensioner roller (flat side in), the take one side and go around alternator and over fan pulley. The other side goes around the crank pulley, around the AC pulley, and up to the PS pump.

You will need to compress the shock to get it on. Peter

__________________

1972 220D ?? miles 1988 300E 200,012 1987 300D Turbo killed 9/25/07, 275,000 miles 1985 Volvo 740 GLE Turobodiesel 218,000 1972 280 SE 4.5 165, 000 - It runs! |

|

#9

|

||||

|

||||

|

thanks

Well, I figured it out. The belt was apparently not the correct one, I had it stored for use later and I must have gotten it wrong somehow. Not sure how it iis possible but it must have happened. I went to the parts shop and compared to a new belt and the new one was about an 1-2 in longer. Bought it and it went on fine. I dont have another MB that could have used this belt I have that wont fit, so I am still baffled as to how it can be wrong, but it is. NOW, the tensioner adjuster nut will not tighten up the belt all the way. I would have to guess the adjsuter bolt is stripped at the top. WOnderful! Thanks for all the help, that was weird. till not tight since the bolt is stripped.

__________________

Christopher Henkel 1990 190E 2.6 - Arctic white SOLD 1986 190E-16v - Blauswartze 1993 300CE - SOLD 2003 W208 CLK 320 Cabriolet - Magma Red |

|

#10

|

||||

|

||||

|

replace tensioner adjuster bolt

Is there any way to replace the tensioner adjuster bolt that i stripped without pulling the tensioner out? It is a pain to pull.

__________________

Christopher Henkel 1990 190E 2.6 - Arctic white SOLD 1986 190E-16v - Blauswartze 1993 300CE - SOLD 2003 W208 CLK 320 Cabriolet - Magma Red |

|

#11

|

|||

|

|||

|

Sorry, no. The link isn't separable from the bolt.

You stripped it because the tensioner rubber is shot, and you must replace the tensioner. Bad design, no way to fix it either short of replacement. That's why I always recommend watching the pointer while loosening -- and you should really just plan on a new one any time you loosen the belt if the tensioner is more than a couple years old. Why Benz didn't use some version of the one on the diesel is beyond me -- just a spring, a shock, and a pivot. Much nicer, although they do fail at the pivot bearing after 250,000 miles or so. Peter

__________________

1972 220D ?? miles 1988 300E 200,012 1987 300D Turbo killed 9/25/07, 275,000 miles 1985 Volvo 740 GLE Turobodiesel 218,000 1972 280 SE 4.5 165, 000 - It runs! |

|

#12

|

||||

|

||||

|

thanks

Thanks, I have replaced one before and remeber it is not fun and didnt remember if the bolt could be removed.

HYPOTHETICALLY...if a guy wanted to just get the belt tight, could you just replace the bolt assembly and leave a bad tensioner in place. WOuld the belt go tight and the car be safe to drive? I know the work time is the same, but the tensioner is anouther $100. Hypothetically speaking, would it work?

__________________

Christopher Henkel 1990 190E 2.6 - Arctic white SOLD 1986 190E-16v - Blauswartze 1993 300CE - SOLD 2003 W208 CLK 320 Cabriolet - Magma Red |

|

#13

|

|||

|

|||

|

This bad tensioner design makes many just use the alternator to remove and install the belt.

Once the lower bolt is removed and the upper bolt loosen, the alternator can swing and the belt can be removed and installed. |

|

#14

|

|||

|

|||

|

No, because the adjuster bolt only turns the inner part, if the rubber is bad, the outer part of the pivot will not rotate far enough to pull the belt up before you run out of room on the adjuster and strip it, or worse, snap the end off.

It's nowhere near as bad as doing water pump on an M103. Peter

__________________

1972 220D ?? miles 1988 300E 200,012 1987 300D Turbo killed 9/25/07, 275,000 miles 1985 Volvo 740 GLE Turobodiesel 218,000 1972 280 SE 4.5 165, 000 - It runs! |

|

#15

|

|||

|

|||

|

The alternator trick does indeed work; I used it this weekend to replace the fan and fan clutch on my 88 300ce. In doing this job I found that my car had the original parts, not the updated fan and clutch which I used from my parts car which I hope will keep the coolant temperatures lower. I already noticed the "new" clutch offered more resistance when turned manually. BTW, thanks to Peter and all the others on this board for their earlier posts providing advice on doing this job and how to make the fan clutch pulley holding tool.

__________________

87 300e (white/black; amg body kit) 88 300ce (red/cream; amg body kit) 93 300ce cabrio (white/blue/blue top) 93 300ce cabrio (black/grey/black top) 98 ml 320 (totaled @ 137,000 miles) 99 clk320 (black/grey/black top) |

|

| Bookmarks |

|

|