|

|

|

|

|

|

|

|

|

|

|

#31

|

|||

|

|||

|

Got my AC recharged and working today in the 92 300TE. It was already converted to 134a, so I just loaded it up. Was trying to figure the proper charge, by weight of 134. Just happened to check my parts car, a 93 300E with a factory 134a system.... folks, the entire systems are IDENTICAL, except the compressor oil and refrigerant. Same evaporator, same condenser and fans, same compressor. 92 calls for 2.4lbs of R12, 93 calls for 2.2lbs of 134a.

|

|

#32

|

|||

|

|||

|

Quote:

True or false: it’s ok to vent more than 10 lbs of refrigerant in to the atmosphere If you can answer that, you are golden.

__________________

Eugene 10 E63 AMG 93 300te 4matic 07 BMW X3 14 Ford F-150 Fx2 |

|

#33

|

|||

|

|||

|

I agree, but I still took the test and got my 609 cert.

Remember big brother's always watching

|

|

#34

|

|||

|

|||

|

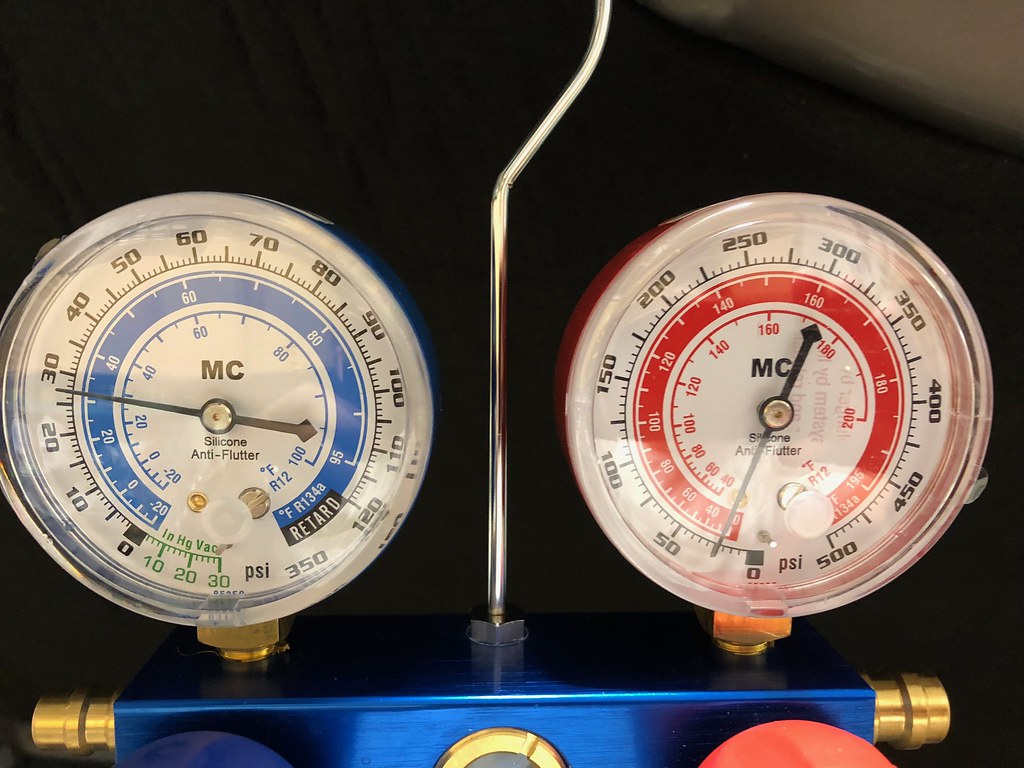

Here are the pressures with the motor off

Untitled by ttownthomas, on Flickr Untitled by ttownthomas, on FlickrAnd with the car running but the HVAC system off - center of pulley NOT spinning  Untitled by ttownthomas, on Flickr Untitled by ttownthomas, on FlickrAnd with HVAC set to max cool - center of pulley spinning  Untitled by ttownthomas, on Flickr Untitled by ttownthomas, on Flickr

|

|

#35

|

|||

|

|||

|

What was the temperature outside? You are definitely low. The low side should be like +30, and high in the 200 psi ish range

__________________

Eugene 10 E63 AMG 93 300te 4matic 07 BMW X3 14 Ford F-150 Fx2 |

|

#36

|

||||

|

||||

|

Definitely very low. For it to be that low, you probably have a leak somewhere too. I'm surprised the compressor is engaging with the pressure that low, the pressure switch on the receiver/dryer is supposed to keep the compressor from engaging when the system is very low.

__________________

Current stable: 1995 E320 157K (Nancy) 1983 500SL 125K (SLoL) Gone but not forgotten: 1986 300SDL (RIP) 1991 350SD 1991 560SEL 1990 560SEL 1986 500SEL Euro (Rusted to nothing at 47K!) Gone and wanting to forget: 1985 524TD 167K (TotalDumpster™) [Definitely NOT a Benz] |

|

#37

|

|||

|

|||

|

Around 60f

|

|

#38

|

|||

|

|||

|

Quote:

Since the compressor dosen't run when the a/c is off I think that means that the electromagnetic clutch on the compresser is good. If the car was drained completely of freon and the compressor still engages we know that the pressure switch must be bad. I might as well fill it with 152a and dye see if it cools and find my leaks. Drain it again and Replace the A/C seals and the pressure switch. If I do this how do I know if the proper amount of oil is remaining in the system? It it as simple as removing the fill hole screw and filling it up? Last edited by ttownthomas; 02-23-2018 at 11:20 PM. |

|

#39

|

||||

|

||||

|

The clutch is good because it engages the compressor. The controls that engage the clutch are questionable, I'd expect at the pressures you have that the clutch would be disabled. I bring it up because if you run it for long like that, you risk tearing up the compressor. It relies on gas circulation to return oil to the compressor sump. When I got my SDL, the Klima relay was stuck closed, so it ran the compressor with no refrigerant and burnt it up. That happened long before I got the car. The compressor was a write-off and the system was a mess. Don't let yours get to that point, it's a lot of extra work that doesn't need to happen.

If you want to do a quick gas & go, buy a couple cans of R12 and top off the charge. See how long it lasts before it leaks out again. If you're going to have the system recovered and filled with new gas, you might as well do the job right. Flush the system out, replace ALL of the O-rings (they're a common leak point), replace the expansion valve with a new one (all the new ones are R134a rated), install a new receiver-dryer, and replace the fan switch and pressure switch on said receiver-dryer (the newer switches have pressures matched for R134a). Pull a deep vacuum, dump in some PAG oil and refill with R134a. The small-tube condenser on the Gen II 126 works fine with 134a, and when matched with the correct expansion valve, the system works very well.

__________________

Current stable: 1995 E320 157K (Nancy) 1983 500SL 125K (SLoL) Gone but not forgotten: 1986 300SDL (RIP) 1991 350SD 1991 560SEL 1990 560SEL 1986 500SEL Euro (Rusted to nothing at 47K!) Gone and wanting to forget: 1985 524TD 167K (TotalDumpster™) [Definitely NOT a Benz] |

|

#40

|

|||

|

|||

|

Quote:

|

|

#41

|

|||

|

|||

|

Here is my plan:

I want to keep running r12 but I need to fix my leaks and replace all the seals first. but before any of that I want to see if the system is functioning correctly. I want to pull a vacuum on the system and then fill it with 152a and dye to find all my leaks AND test the rest of the system. What do I do about oil with the 152? Should I check the level at the compressor when it is empty? Just add a little for good measure? What oil should I use? |

|

#42

|

||||

|

||||

|

If you change refrigerants, you need to flush the system and refill with PAG oil. 134a and 152a both require PAG oil. R12 uses mineral oil. The importance comes with how the oil circulates, R12 is miscible in mineral oil, so it is carried along with the gas charge. 134a and 152a are not miscible in mineral oil, so it will not carry it through the system. You run the risk of starving the compressor for oil, or oillogging the condenser or evaporator.

If you're sticking with R12, stick with R12. I did that originally in my SDL, but after about a month and a half of use, the expansion valve got stuck open and stopped cooling. You can't buy a new R12 rated expansion valve (different orifice size than R134a), so I converted the system at that point. When the conversion is done correctly (flushed, filled by weight, correct expansion valve) there's not much difference in performance on these later W126's. Early 126's and the W123's had a crappy condenser that was barely adequate for R12. The Gen II's have a small-tube double-circuit condenser that's much more efficient with the newer refrigerant. The SDL cools just as good if not better than most modern vehicles in my climate and I don't even have the windows tinted...

__________________

Current stable: 1995 E320 157K (Nancy) 1983 500SL 125K (SLoL) Gone but not forgotten: 1986 300SDL (RIP) 1991 350SD 1991 560SEL 1990 560SEL 1986 500SEL Euro (Rusted to nothing at 47K!) Gone and wanting to forget: 1985 524TD 167K (TotalDumpster™) [Definitely NOT a Benz] |

|

#43

|

|||

|

|||

|

Quote:

|

|

#44

|

||||

|

||||

|

Flushing the system involves opening up the lines and sending a flush solution through it. It isn't difficult. You'll want to drain the sump of the compressor too.

After flushing, replace the O-rings, pressure switches, and receiver/dryer. There are decent aftermarket parts out there. Modern replacement parts are designed for the pressures and lubricants used in 134a systems, just another reason to convert it if you're going that far.

__________________

Current stable: 1995 E320 157K (Nancy) 1983 500SL 125K (SLoL) Gone but not forgotten: 1986 300SDL (RIP) 1991 350SD 1991 560SEL 1990 560SEL 1986 500SEL Euro (Rusted to nothing at 47K!) Gone and wanting to forget: 1985 524TD 167K (TotalDumpster™) [Definitely NOT a Benz] |

|

#45

|

||||

|

||||

|

FWIW I ran the 300E on mineral oil and 152A until it met its demise New Years Eve. That was three years worth on the original compressor.

You would be fine to charge it and get it cooling.

__________________

I'm not a doctor, but I'll have a look.  '85 300SD 245k '87 300SDL 251k '90 300SEL 326k Six others from BMW, GM, and Ford. Liberty will not descend to a people; a people must raise themselves to liberty.[/IMG] |

|

| Bookmarks |

|

|