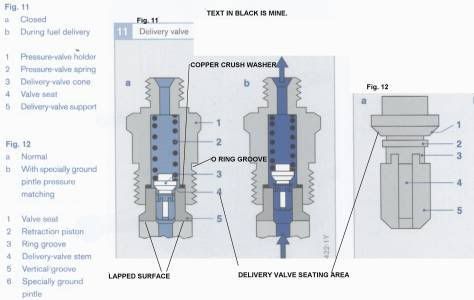

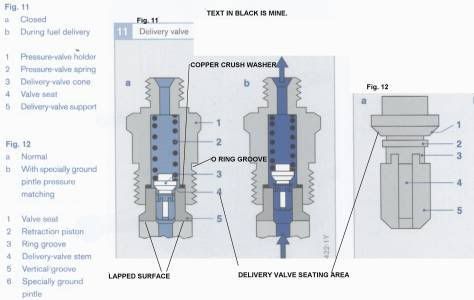

I am going to add some speculation: The delivery valves have seats that they ride in (they do not rotate) and wear in to their seats. When you remove them and (I hope) clean them they do not go back into exactly the same position (of course each delivery valve has mated parts that should not swapped around) so the seats that they wore into are now disturbed.

I am speculating that the sound goes away after X number of miles for most people after these valves have worn themselves a new seat (reseated themselves).

Colud the delivery vlaves be scribed with a mark so that the valve parts go back into the same position?

Could the delivery valves be reseated with some very fine lapping compoud (500-600 grit) only on the seating area (as engine valves are lapped) before being reinstalled and the "nailing" eliminated?