|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

OM601: Valve Timing and IP Timing Assistance Needed

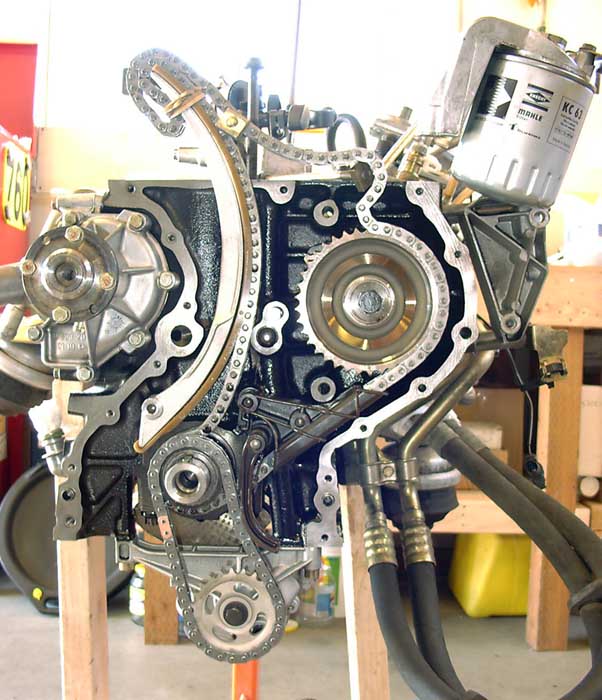

I am in the process of getting the OM601 ready to go back into my 1984 190d 2.2 non-turbo. You may recall my engine rebuild fiasco with a local machine shop. http://www.peachparts.com/shopforum/diesel-discussion/342623-need-good-machine-shop-d-fw-texas.html I believe that I have the timing done and am going to begin putting everything back together and preparing for the IP timing. I have purchased the IP locking tool and the wrench to turn the ip to its proper location for timing.

Please take a look at the photos that I have posted and double check my work thus far as far as the timing goes. I purchased the OM601 FSM and have been following it to a T. I still need to install the timing cover before timing the IP, but I want to make sure that everything is correct before potentially destroying gaskets on pulling everything back apart. If you see anything that looks awry, please let me know. Any help/feedback is greatly appreciated.

Last edited by jab0028; 01-23-2014 at 10:10 PM. Reason: edit title |

|

#2

|

||||

|

||||

|

What wrench do you need to turn the IP and why do you need to turn the IP?

Sixto 87 300D |

|

#3

|

|||

|

|||

|

Quote:

I need to make sure that it is lined up as close as possible so that I get as near optimal performance as possible. I need to make sure that it is lined up as close as possible so that I get as near optimal performance as possible.

|

|

#4

|

||||

|

||||

|

If the Fuel Injection Pump is out of the Engine install the Timing/Locking Pin and rotate the Fuel Injection Pump Camshaft unit the Timing/Locking Pin lockes the Fuel Injection Pump Camshaft in place.

Rotate your Engine Crank Shaft in the direction of rotation past TDC on the Compression Stroke to what ever the degrees (about 14-15 ATDC; you will need to look up the spec for your Engine ) are ATDC (After Top Dead Center past TDC on the Compression Stroke) and install the Fuel Injection Pump and bolt it down and remove the Timing/Locking Pin. All of the above should be detailed in your Manual. Before you start rotating the Engine; even by hand you ought to Oil up the Chains and Chain Guide and the Camshaft Lobes. If not then before you assemble the Covers over those items. You especially don't want a Dry Chain running over the Shoe on the Timing Chain Tensioner/Guide Rail. The Engine looks very dry; you use any sort of Assembly Lube on the Engine and Camshaft Bearings? At least pre-lube with Oil. Some of the methods of pumping Oil into the Engine to pre-lube may not gett Oil to the Timing and Oil Pump Chains.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#5

|

||||

|

||||

|

Quote:

There is a groove on both ends of the Timing/Locking Pin Plunger. That groove needs to be oriented Horizontal/Parallel to the length of the Fuel Injection Pump Camshaft be fore you start to turn the Fuel Injection Pump. I used the Timing Locking Pin in the Below Thread the method is the same but you need to know which degrees ATDC for your specific Engine: http://www.peachparts.com/shopforum/showthread.php?t=297458

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#6

|

||||

|

||||

|

Gus Pfister himself (Bay Area 02 | Features | Gus Pfister Interview and Story) told me to wrap a rag around the IP shaft and use pliers to turn the shaft.

But again, why didn't MB make the base RIV position TDC??? Sixto 87 300D |

|

#7

|

||||

|

||||

|

I rotate them with pliers and a rag.

Your engine is so clean and pretty!

__________________

http://superturbodiesel.com/images/sig.04.10.jpg 1995 E420 Schwarz 1995 E300 Weiss #1987 300D Sturmmachine #1991 300D Nearly Perfect #1994 E320 Cabriolet #1995 E320 Touring #1985 300D Sedan OBK #42 |

|

#8

|

||||

|

||||

|

Quote:

Hmm... I get the sense you're doing things a little backwards. I'd have installed the front cover before installing the head to use a dial gauge to confirm the crank pulley gradients and the [IMO idiotically] adjustable pointer coincide with #1 TDC. At this stage the front cover has to go on so you can set the crank to 14-15* ATDC. I hope you didn't loosen or remove the pointer in quest for hermetic cleanliness. Sixto 87 300D Last edited by sixto; 01-24-2014 at 04:09 PM. |

|

#9

|

|||

|

|||

|

Thanks for all of your responses. I do have the locking tool, I also purchased a socket that I thought would fit the IP similar to the one pictured but it is too small. I will just turn it by hand. As far as the timing cover going on before the head, I didn't have a chance to do so. The shop was supposed to do a more complete assembly, but failed to do so. I will have to be careful not to pinch the head gasket as I line up the front cover. Also the FSM says to set the engine at 15 degrees before installing the pump.

The engine also appears to have some assembly lube on certain areas, but not in the areas that you mention. I will be sure to add additional lube to the areas that you mentioned. Thanks. |

|

#10

|

||||

|

||||

|

Quote:

Sixto 87 300D |

|

#11

|

|||

|

|||

|

Quote:

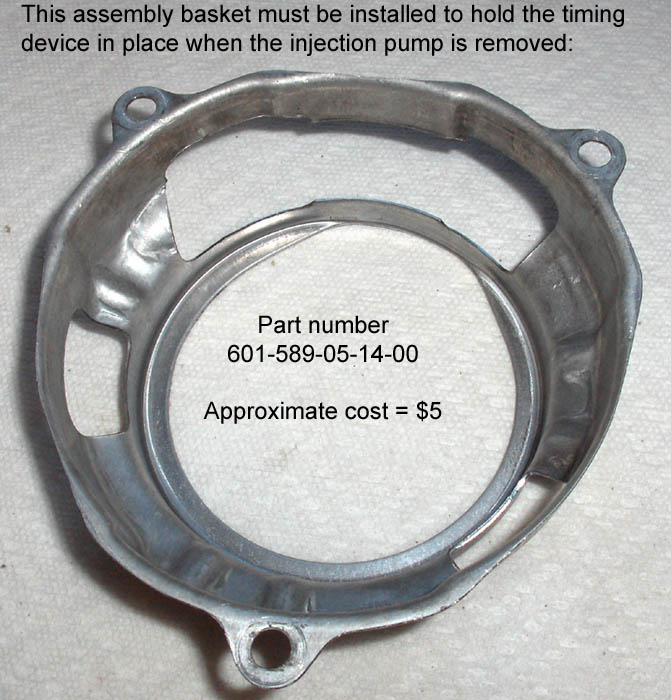

I think that you are right about the 15 degrees. The timing device is currently just sitting on the chain sprockets. They used baling wire to hold it in place when I went to pick it up. I may have to try and hunt down that tool that you mention. |

|

#12

|

||||

|

||||

|

No matter what you do when the Engine is assembled turn the Crank Shaft a bunch of revolutions by hand to see if any hangs up. That way if for some reason the Valve timing ended up off and a Valve makes contact with a Piston you will do no damage and it can be corrected.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#13

|

|||

|

|||

|

Quote:

Quote:

|

|

#14

|

||||

|

||||

|

Quote:

Umm... thanks to MB's crazy price increases, the assembly basket list price is $250 this year  Again, though, the tool attaches to the front cover. No front cover, no way to use the tool. Slap the IP in place, prime and install the chain tensioner, confirm cam timing, set the crank to 15* ATDC, remove the IP, install the IP locking tool, install the IP. The first installation of the IP is simply to hold the IP timer sprocket. You'll have to get creative holding the IP to the block without the front cover. Using this picture as a reference...  Use spacers to simulate the front cover to use the IP bolts that go into the holes at the 4-, 7- and 11 o'clock positions relative to the IP timer sprocket. The retaining nuts are square jobs that fit into slots in the IP flange. You won't need spacers if the bolts are threaded far enough up the shank an there's nothing in their way on the far end. Your call whether to fit the tail end bracket if a 601 has such a bracket. Sixto 87 300D Last edited by sixto; 01-26-2014 at 04:38 PM. |

|

#15

|

|||

|

|||

|

I have got the front cover on and am cleaning up the IP now. I am going to fit everything up and just put the IP on and set the engine to the 15* then remove the IP and set it properly. Thanks for all of the good advice.

|

|

| Bookmarks |

|

|