|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

617 turbo valve adjustment lobe position

I adjusted the valves last night on my 83 300D. I reviewed old ShopForum threads as well as threads all over the web.

I have two questions: 1.When I position the lobe at "1 o'clock" does the tip of the lobe point to the driver's side or passenger side of the car? My MB service manual says: "positioning the camshaft so that the tip of the cam is vertical relative to the rocker arm." but the picture in the manual does not show the tip or lobe on on the camshaft in the diagram. Diesel Giant says: "To your eye this will look like the lobe is in about the 1 o'clock position" but the tip of the camshaft lobe in his picture looks to me like it is pointing toward the passenger side of the vehicle, (the engine he is working on is a 617 non-turbo). 2.Can I lube the linkage with regular wheel bearing grease after I clean them? Thanks for the help. I have two more valve adjustments to go. Bob |

|

#2

|

||||

|

||||

|

Quote:

|

|

#3

|

||||

|

||||

|

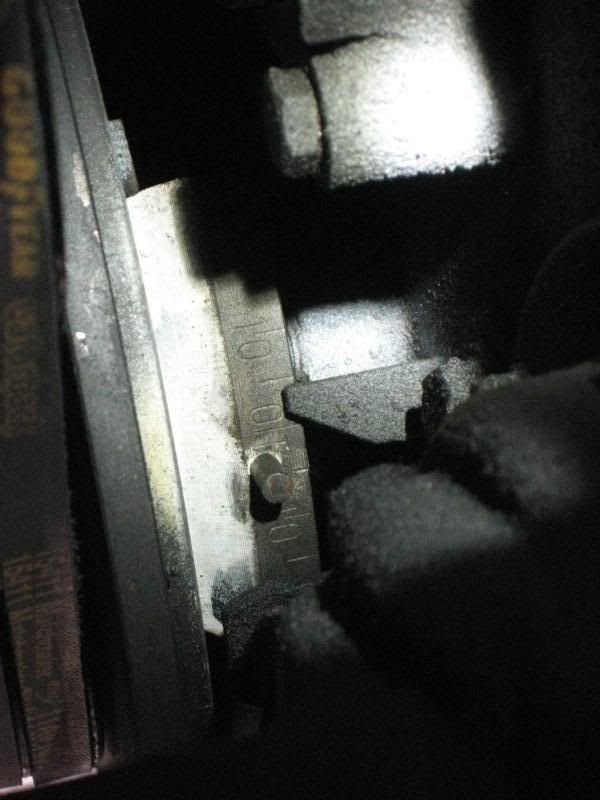

I stood on the drivers side using a bump starter and positioned the lobe as pictured here, which would be also pointing to the drivers side

I used trans fluid to lube the linkage |

|

#4

|

|||

|

|||

|

Thanks for the feedback Guage, I interpreted things just as you.

|

|

#5

|

|||

|

|||

|

Quote:

Bob |

|

#6

|

|||

|

|||

|

Quote:

However, there were a couple of members who noted a difference in readings when the cam was moved from 12:00 to 1:00...........so, YMMV. As Gauge mentioned, if you use the 1:00 position, it's toward the driver's side. |

|

#7

|

|||

|

|||

|

Quote:

I think I have read every thread on ShopForum and the rest of the net and understood there was some varied opinions. I intentionally did this on my junker 300D before working on two cars with good engines. I was a little disappointed after I finished the job because the car still has really poor compression and wanted to make sure I did the procedure correctly. The valves on the car had no clearance prior to adjustment so I was hoping for the best. Bob |

|

#8

|

|||

|

|||

|

Quote:

..........there goes the compression......... |

|

#9

|

||||

|

||||

|

Had I known... while mine was apart.....I would have used a dial indicator to read the base of the lobe to see if there is a difference and if so...where the "sweet spot" is.

__________________

1983 300SD 272,000 Miles "Aristotle" 1987 Jeep Wagoneer Limited - keeps the MB's off the ice and out of the snow 1994 BMW 530it |

|

#10

|

||||

|

||||

|

Hello, just did an adjustment on mynew to me 82 300cd. I used the metal bar that stretches across all the cam towers as the reference point. That put me a bit beyond 1 o'clock but it looked right per the manual pictures.

Does anyone just align the lobe with the metal bar? I havent done an adjustment since about 2003, and hope I didn't do it wrong. All were tight - I'll post the values later. I thought it was due to being due... Thanks!

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (116k) 1991 350SD (206k) 1991 300D (228k) 2008 ML320 CDI (199k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (267k) Past Diesels: 1983 300D (228K), 1985 300D (233K), 1993 300D 2.5T (338k), 1993 300SD (291k) |

|

#11

|

||||

|

||||

|

YES

Quote:

Everything you need to do it correctly is here.. Valve adjustment OM617 FYI. Valve adjustment OM615, 616, 617 FYI. Have a great day.

__________________

ASE Master Mechanic https://whunter.carrd.co/ Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 2003 Volvo V70 https://www.boldegoist.com/ |

|

#12

|

|||

|

|||

|

Quote:

|

|

#13

|

||||

|

||||

|

Thanks.

So you line up (or point) the "tip" of the cam lobe with that tube? My main concern is because before adjusting, I had the following readings: #1E: .203mm #1I: .152mm #2I: .127mm #2E: .229mm #3E: .254mm #3I: .173mm #4I: .179mm #4E: .229mm #5E: .229mm #5I: .102mm So I had set each cam lobe to point exactly to the oiler tube on the cam towers. It matches up to the instruction pictures that way IMO, and also the cam is round for 120 degrees or so, Id guess there shouldn't be much variability, but those were pretty far off from the .10mm in and .35mm out per the sticker on the car. The interesting thing to me is, if they were done "right" last time, then while the exhausts all got tighter (expected), the intakes all got looser, how is that? The other option is that the last time the wrong specs were used. Car idled and ran perfectly with those old settings. Going cross-country, I got mid 28 MPG, averaging 75 MPH, and spending time above or near 7500 ft. One other thought/question. I did this job roughly at freezing. The car was definitely cold soaked, having not been used for over a week. Could this be "too cold", and cause me issues again later when ambient gets warmer? Chain stretch at TDC: 4 degrees

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (116k) 1991 350SD (206k) 1991 300D (228k) 2008 ML320 CDI (199k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (267k) Past Diesels: 1983 300D (228K), 1985 300D (233K), 1993 300D 2.5T (338k), 1993 300SD (291k) Last edited by JHZR2; 12-06-2009 at 10:57 PM. |

|

#14

|

|||

|

|||

|

As clear as the FSM states where the cam lobe is supposed to point I can not believe there could be this much discussion about it.

If a person is having trouble getting and keeping the proper tolerance during valve setting the FSM suggests putting new cap and lock nuts on the valves as a first and cheap possible fix for the situation. They take a lot of pressure and pounding...so they can get worn on the threads and make it hard to hold the correct distance through the tightening process.

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/diesel-discussion/10414-help-i-need-check-stretch.html http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#15

|

||||

|

||||

|

As clear as the image is in the manual and in haynes type manuals, Im suprised that it is not mentioned that the oiling tube can be used as a reference point. It sure seems to line up right for me. But for those of us who have never really had to do this job before, and see it as a task with much to loose beause of a general lack of full understanding... it is important to have a sense of correctness and surety to the process.

Still, it helps to have a sounding board to ensure that my thought process and technique is absolutely correct, or not. Sure seem to see conflicting stuff, from vertical to one o'clock... Im referencing the graphic for angle and design of the system. One thing that I did not do was crank all around and then recheck. Hope they are OK. The nuts all worked fine. Some needed a bit of oomph to loosen, but they worked, loosened and tightened just fine.

__________________

Current Diesels: 1981 240D (73K) 1982 300CD (169k) 1985 190D (169k) 1991 350SD (116k) 1991 350SD (206k) 1991 300D (228k) 2008 ML320 CDI (199k) 1996 Dodge Ram CTD (442k) 1996 Dodge Ram CTD (267k) Past Diesels: 1983 300D (228K), 1985 300D (233K), 1993 300D 2.5T (338k), 1993 300SD (291k) |

|

| Bookmarks |

|

|