|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

#16

|

||||

|

||||

|

Quote:

|

|

#17

|

|||

|

|||

|

How would the loosening of the camshaft bearing caps compare to an om601 engine?

__________________

Dave 1985 190D 2.2 auto--gone 1975 240D 4-speed--storage 1985 500SEL--daily driver 1985 300TD--bad rust, soon to part out... 1982 300SD--waiting on engine from RD 1984 190E--storage 1996 Dodge 2500 Cummins--daily driver |

|

#18

|

|||

|

|||

|

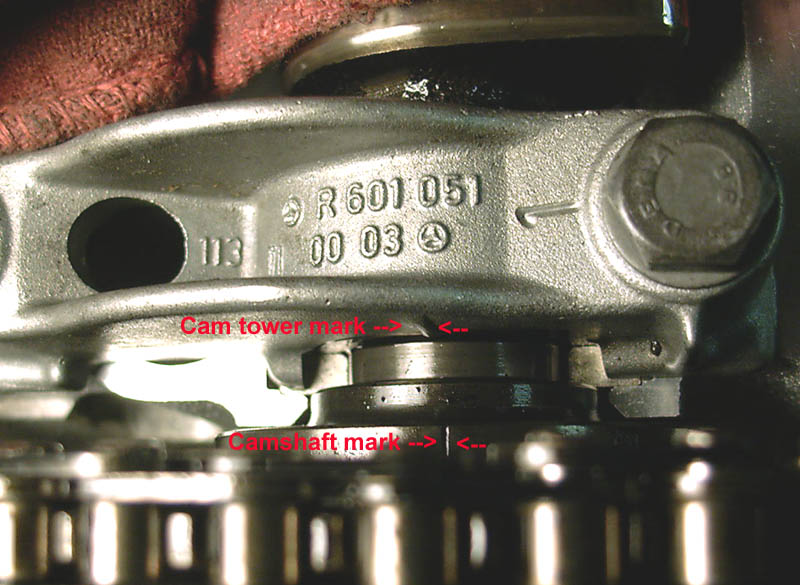

See attached drawings for the 601 (and the 603, just for completeness). As mentioned earlier, this sequence relies upon the engine being at TDC before beginning.

__________________

1989 250TD Wagon 5-speed, 160,000mi ::: Dark gray metallic / black cloth 1984 190D-2.2 5-speed, 287,000mi ::: Silver-blue metallic / black MB-tex ::: SOLD

|

|

#19

|

|||

|

|||

|

Hey thanks cornblatt. That will come in handy in a couple of weeks

__________________

Dave 1985 190D 2.2 auto--gone 1975 240D 4-speed--storage 1985 500SEL--daily driver 1985 300TD--bad rust, soon to part out... 1982 300SD--waiting on engine from RD 1984 190E--storage 1996 Dodge 2500 Cummins--daily driver |

|

#20

|

||||

|

||||

|

Complete!

Hey guys,

just wanted to say I did mine today and completed it in about 4-5 hours. I work slow and constantly misplace my tools, plus a small lunch break. The advice from gsxr and cornblatt was indispensable, thankyou! my car is running ever so smooth and quiet now. No more annoying lifter noise at the DD drivethru  I took a few pics that I will post up later. IfI could offer some advice, be careful taking the timing chain tensioner out. I 'accidently' took off the inner bolt (19mm), and the guts came flying out. Becareful. Everything else was pretty much textbook. My timing was only about .5 to 1.5 degrees off. It looked pretty spot on, my eyesight might have been a little off lining up the cam and the sprocket, but it was definetely in that range.What is acceptable?

__________________

93 300D 2.5 Turbo, Black/Palomino 273K 09 E350 Black/Black 41K |

|

#21

|

||||

|

||||

|

Quote:

http://www.w124performance.com/docs/mb/OM60X/OM60x_Timing_Chain_TSB.pdf

|

|

#22

|

||||

|

||||

|

Odd that the 3.0L 603 is excluded, wonder why?

__________________

Gone to the dark side - Jeff |

|

#23

|

||||

|

||||

|

You mean from the timing chain TSB? Simple explanation. The 3.0L 603 motor (603.96x) was only shipped to the USA in 1986 and 1987. I believe the TSB is for MBNA only, not worldwide. So only the engines in the USA were affected, from 1990-95, which were the 2.5L (602.962) and 3.5L (OM603.97x).

On second look... the TSB does not specify displacement at all, only engine type (602, 603, 606) and month/year of manufacture.

|

|

#24

|

||||

|

||||

|

A few pics...

1st: 10 fresh new lifters 2nd: OCD on the zip ties 3rd: Using my magnet to remove the lifters

__________________

93 300D 2.5 Turbo, Black/Palomino 273K 09 E350 Black/Black 41K |

|

#25

|

||||

|

||||

|

Some questions!!

Quote:

-What's the torque (nm) when screwing back the screws on the camshaft? -What's the torque (nm) when screwing back the screws on the valve cover? -Do I have to substitute the valve cover rubber gasket? -Mine's an OM601, so there's 8 lifters? -When screwing back the chain tensioner do I have to put a new gasket or silicon will do it? Thanks in advance for your replies guys! With kind regards

__________________

--------------------------------------------------- Mercedes fanatic 1985 200D (w124) and totaled 190D |

|

#26

|

|||

|

|||

|

Quote:

- 10Nm for the valve cover - Probably not. I just clean everything thoroughly each time (push some rags or paper towels inside the groove on the gasket and soak up all of the oil). I've reused the same gasket 4 or 5 times now with no leaks. - Yes, that's right. - No to both; you could probably re-use the existing metal washer/gasket.

__________________

1989 250TD Wagon 5-speed, 160,000mi ::: Dark gray metallic / black cloth 1984 190D-2.2 5-speed, 287,000mi ::: Silver-blue metallic / black MB-tex ::: SOLD

|

|

#27

|

||||

|

||||

|

Quote:

Thanks for the fast replly, I'll do the procedure and then post the results!! Thanks again

__________________

--------------------------------------------------- Mercedes fanatic 1985 200D (w124) and totaled 190D |

|

#28

|

||||

|

||||

|

Did the procedure today, something didn't went ok!!

I aligned the camshaft and the cam tower and got at the crankshaft 2º BTDC, is it normal to be before?? Plenty of zip ties and marked the chain and the sprocket with a pen just to be safe!!! Assembled everything and now the car has a very rough idle, just about hanging there!!!! Took the valve cover off, aligned the cam and cameshaft, got the 2º BTDC, just fine but.......the mark i made with the pen was off by 4 teeth!!!! And now????? Am I screwed??

__________________

--------------------------------------------------- Mercedes fanatic 1985 200D (w124) and totaled 190D |

|

#29

|

||||

|

||||

|

Quote:

2° BTDC is odd, but my car did the same thing. Make sure you are reading the crank indicator properly, the line should be to the left of the indicator, not dead center on the line. You may be reading 0° TDC. Also, the indicator is adjustable within a 3° range... if someone moved it, the reading may not be accurate. It must be set with a dial gauge on the piston crown. In general, the setting ends up right in the middle of the 3° range (±0.5 degrees) on most engines. If your crank & cam line up now (within a degree or two), I would check the IP timing next. Did you touch anything else besides the timing chain?

|

|

#30

|

||||

|

||||

|

I was reading the scale in the wrong direction, it's 2º ATDC so in spec!

I followed the procedure word by word, I don't see what could go wrong, If the problem is the IP timing, how could have that happen??

__________________

--------------------------------------------------- Mercedes fanatic 1985 200D (w124) and totaled 190D |

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|