|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

Oil cooler repair - help needed...

Yesterday, my dad and I tackled the oil cooler line replacement project. It started out well, we were able to get the fitting off the oil housing with no problems (thanks Dieselgiant for the tip on the special tool).

Then, the upper one on the oil cooler itself came off with no problems whatsoever... but the lower line on the cooler was stuck rock hard - using plenty of PB Blaster, and gently trying to persuade it only resulted in stripped threads - see the photo. So now I have another project - fixing the threaded nipple. Reading through some of the posts on this forum, I was able to find an excellent thread on the topic: are the oil cooler fittings replaceable by themselves? I ordered the parts from my local dealer (I guess nobody in CO carries it) - the part referenced in the thread was # 915013-013002. Should arrive on Tuesday, meanwhile, questions on the actual repair for those of you who fought through this already: what are some of the steps for installing the patch fitting. Reading below it seems we need to cut off the nipple with the stripped threads back to the nut that's permanently attached to the cooler - that's clear, but drilling a pilot hole is confusing me... Why would we need to drill a pilot hole - isn't there already a big hole in the place where we just cut the nipple?! Wouldn't we just tap the big gaping hole in the oil cooler? Obviously I'm missing something.... and any help here would be appreciated - Here is the direct quote from someone on the above thread: "... All I had to do is cut the aluminum threads off the oil cooler, drill a pilot hole, tap new threads, and install the new fittings. The thread tap size is 18mm by 1.5mm. The drill size for the pilot hole is 21/32 inches, I don't know the metric equivalent. It took a local machinist 15 minutes to cut off the aluminum threads back to the nut part, drill the pilot holes (there's plenty of metal there), and tap the new threads. It took longer to rinse out all the aluminum filings and grit out of the cooler than it did to work on it. Here are the MB part numbers for the threaded oil line fittings and copper washers. MB Part # Description 915013-013002 Screwed Nipples (That's what the label said.) 007603-018101 Ring, General, Metal"

__________________

1987 Mercedes 300SDL; SOLD 1985 Mercedes 300D; SOLD  2006 Honda Pilot - wife's ride; 122K; 1995 Toyota Land Cruiser - 3X locked; 182K |

|

#2

|

|||

|

|||

|

I assume the 'big gaping hole' is not quite big enough and needs to be enlarged to accept the tap.

__________________

1977 300d 70k--sold 08 1985 300TD 185k+ 1984 307d 126k--sold 8/03 1985 409d 65k--sold 06 1984 300SD 315k--daughter's car 1979 300SD 122k--sold 2/11 1999 Fuso FG Expedition Camper 1993 GMC Sierra 6.5 TD 4x4 1982 Bluebird Wanderlodge CAT 3208--Sold 2/13 |

|

#3

|

||||

|

||||

|

Still not quite clear...

Understand, but why would there be a mention of needing a pilot hole... that's the confusion I guess. Will probably get a better feel for the job when the part arrives...

__________________

1987 Mercedes 300SDL; SOLD 1985 Mercedes 300D; SOLD  2006 Honda Pilot - wife's ride; 122K; 1995 Toyota Land Cruiser - 3X locked; 182K |

|

#4

|

||||

|

||||

|

Quote:

You might try this if you think the threads that are left can be restored. See Post #13: striped threads on oil cooler

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#5

|

||||

|

||||

|

Looks like only one option left...

Quote:

Since I'll be pursuing cutting off the nipple at the nut and tapping the hole I'll need to clean the shavings and such out of the oil cooler after the fact. What's a good substance to use for - is common Brake Cleaner ok for that job?!

__________________

1987 Mercedes 300SDL; SOLD 1985 Mercedes 300D; SOLD  2006 Honda Pilot - wife's ride; 122K; 1995 Toyota Land Cruiser - 3X locked; 182K |

|

#6

|

||||

|

||||

|

Quote:

The good news is that the Oil that Goes through the Oil Cooler is un-filtered Oil. The Oil returning from the Oil Cooler goes back to the filter housing to pass through the Oil Filter before going into the Engine. If you mean what to soak the whole Oil Cooler in; I believe I have read members have used Diesel Fuel or Biodiesel. Brake Cleaner would work but I am not sure if you mean to Spray it from Spray Can or use it as a flush from a 1 gallon can? If you are going to get a Gallon of Brake Cleaner you could just as well buy 1 Gallon of Slovent instead. I believe all of the above will work.

__________________

84 300D, 82 Volvo 244Gl Diesel Last edited by Diesel911; 05-11-2009 at 12:13 AM. |

|

#7

|

||||

|

||||

|

"pilot hole" should have been "tap drill hole". You may want to verify the 18 x 1.5 size, I was not able to find it in the chart below..

http://www.newmantools.com/tapdrill.htm

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#8

|

||||

|

||||

|

Tools...

Found this: http://www.restockit.com/High-Carbon-Steel-Metric-Thread-Spark-Plug-Tap-Plug-18-mm-1-50-(VER21164).html

Says it's 18mm x 1.5 mm and the drill size is 21/32nd - hoping that's the one.... I'll need to try it out on something first.

__________________

1987 Mercedes 300SDL; SOLD 1985 Mercedes 300D; SOLD  2006 Honda Pilot - wife's ride; 122K; 1995 Toyota Land Cruiser - 3X locked; 182K |

|

#9

|

||||

|

||||

|

Quote:

When I looked at several Tap Drill charts I found that all of them did not agree with each other. But, the drill I bought is the one that at least 2 members have actually used. So the one actually used by the members must have worked.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#10

|

|||

|

|||

|

I'm replacing oil cooler lines this upcoming weekend, and hopefully they come out with no issues. They did not come out nice from the parts car.

__________________

On some nights I still believe that a car with the fuel gauge on empty can run about fifty more miles if you have the right music very loud on the radio. - HST 1983 300SD - 305000 1984 Toyota Landcruiser - 190000 1994 GMC Jimmy - 203000 https://media.giphy.com/media/X3nnss8PAj5aU/giphy.gif |

|

#11

|

||||

|

||||

|

Small oil leaks...

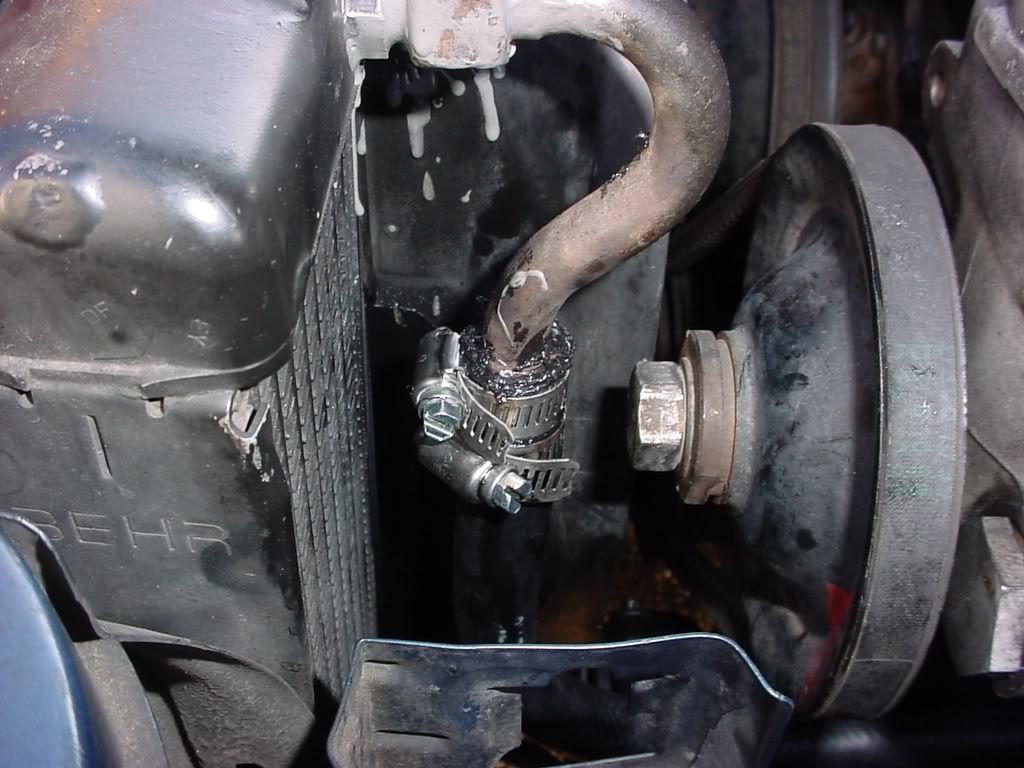

Today dad and I worked on the cooler lines again. Had the cooler out already with the broken threads, so we cut off the nipple, drilled out a bigger hole with 21/32 drill, tapped the hole with 18mm x 1.5mm thread, cleaned it all out of junk real good and screwed in the fitting with a copper washer.

We were feeling really good about this fix, but in the process I believe we have made one key mistake: we didn't cut the nipple flush with the nut on the cooler housing. Instead, we wanted to have a bit more metal to screw the new fitting into so we left extra 3 mm or so above the nut. In retrospect we should not have done that. That cut must not have been exactly straight (we used a hacksaw) and even after some careful filing to get it even it must not have been perfectly flat because it leaked between the copper washer somewhere. It's a small leak but it's a leak nevertheless, so I'll need to deal with it. Luckily I have no leaks a the oil filter housing... whew! So what's my best bet at this point - note that I have everything assembled now... wondering if I should either: a) take the cooler out again and cut the nipples flush with the nut and then use a new copper washer, or b) just remove the lines and replace the copper washers with new crush washers - hoping that the new copper washer would compensate for the uneven surface that remains... Not sure, but it seems that option (a) is what I probably will do - probably should not take shortcuts here. Hopefully I won't have to drain all of the oil again. Any advice would be welcome. James Here is a pic of the almost successful fix -

__________________

1987 Mercedes 300SDL; SOLD 1985 Mercedes 300D; SOLD  2006 Honda Pilot - wife's ride; 122K; 1995 Toyota Land Cruiser - 3X locked; 182K |

|

#12

|

||||

|

||||

|

I'd just find a replacement at the JY.

-From the guy with too many spare parts JIC.

__________________

http://superturbodiesel.com/images/sig.04.10.jpg 1995 E420 Schwarz 1995 E300 Weiss #1987 300D Sturmmachine #1991 300D Nearly Perfect #1994 E320 Cabriolet #1995 E320 Touring #1985 300D Sedan OBK #42 |

|

#13

|

||||

|

||||

|

FYI

Quote:

Engine oil cooler line issue link thread Engine oil cooler and hose/line issue, link thread Have a great day.. |

|

#14

|

||||

|

||||

|

Unscrew the repair nipple and degrease the internal threads and the threads on the of the repair Nipple that thread into the Oil Cooler. Coat the Repair Nipple threads that go into the Oil Cooler with JB Weld (or another slow setting Epoxy that can take the heat) and install the Repair Nipple. Follow the directions as to how long to let it cure to harden it.

If for some reason the temperature is lower then it shoud be to cure; someone will have to stand there with an Electric Hair Dryer and keep it warm while it cures (do not use a heat gun as it might get too hot and un-solder something). If you degrease the threads well there is no reason why the JB Weld will not seal and hold the pressure. I lost some threads on my upper Oil Cooler Nipple and used JB Weld on the origional threads (partly seen middle top) to make sure mine seals. It has been taking the heat and the pressure for at least 1 1/2 years now.

__________________

84 300D, 82 Volvo 244Gl Diesel Last edited by whunter; 05-10-2010 at 05:55 PM. Reason: attached picture |

|

#15

|

||||

|

||||

|

Even if you had cut the old threads off straight it is hard to hold a Drill Motor by hand and drill a straight hole (and with a big drill Aluminum can be kind of grabby and jerky), and because Aluminum is soft it is also easier to tap a hole slightly crooked.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

| Bookmarks |

|

|