|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

Engine Cleanup

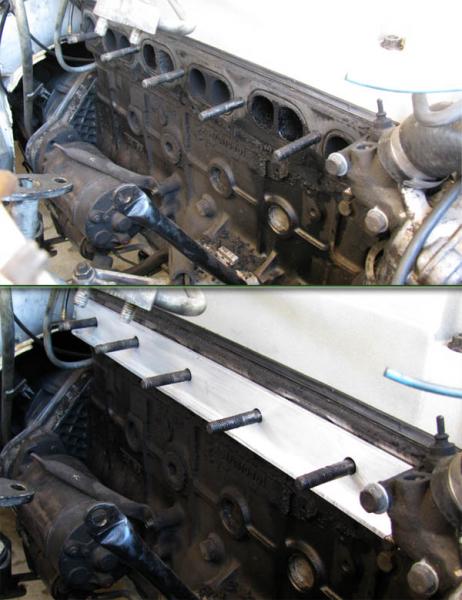

As part of the process of installing the "test pipe", in the 107 diesel, I thought it would be a good time to get the engine cleaned up. I had to pull the turbo and manifolds so the entire side of the engine is exposed for cleaning.

The intake manifold was an absolute mess, but it cleaned up nicely.  The turbo and exhaust manifold are next. I want to thoroughly degrease and pressure wash the engine so I needed a way to protect the ports while I do the job - this is what I came up with.   It's a piece of 3/16" angle aluminum. I'll use the old gasket and smear it with grease then cinch down the port protector to provide a water tight seal. I originally thought that the angle would provide some needed dimensional stability, but I don't think so, so I cut most of the angle off.

__________________

Current Stable

|

|

#2

|

||||

|

||||

Looking good Looking good

__________________

1983 Toyota Tercel 4WD Wagon - 1984 Mercedes-Benz 300SD 4-Speed(My Car!) 2005 C230 Kompressor 6-Speed Manual

|

|

#3

|

||||

|

||||

|

Good time to test fit a non-trap turbo setup

Sixto 87 300D^2 |

|

#4

|

||||

|

||||

|

You mean something like this?

__________________

Current Stable

|

|

#5

|

||||

|

||||

|

You know what I meant

Sixto 87 300D^2 |

|

#6

|

||||

|

||||

|

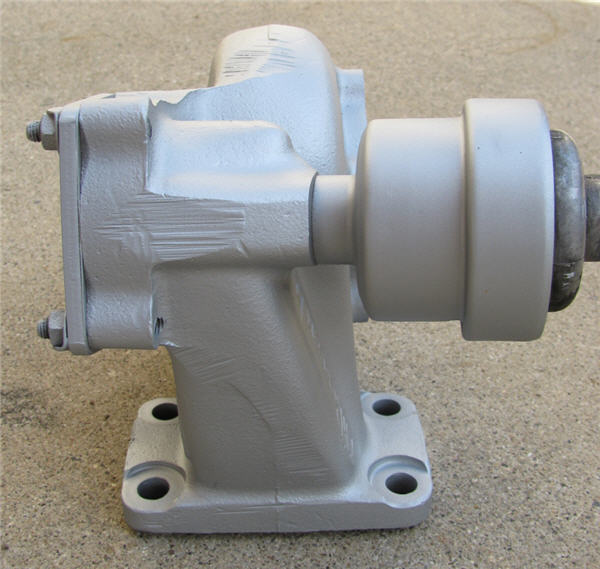

Continued with cleaning up engine components. Focusing on the exhaust section now.

Here's a before, during and after picture of the exhaust manifold. In prep for paint, I wire brushed it, then media blasted it and then painted it with VHT header paint.  I then did the down tube.  Then the turbine housing   And I fabbed up a new test pipe and painted it with VHT header paint to match.  Now when my gasket kit comes in, I'll be ready install everything.

__________________

Current Stable

|

|

#7

|

||||

|

||||

|

#8

|

|||

|

|||

|

I hope the paint is tough enough to stay on e the exhaust parts from the heat.

Check out these guys. Caps Brite Hot Coatings | Powder Coatings, Ceramic Coatings, Cermakrome, And More I have seen their stuff and it looks good, they aren`t new kids on the block, they have been doing this for over 20 years. Charlie

__________________

there were three HP ratings on the OM616... 1) Not much power 2) Even less power 3) Not nearly enough power!! 240D w/auto Anyone that thinks a 240D is slow drives too fast. 80 240D Naturally Exasperated, 4-Spd 388k DD 150mph spedo 3:58 Diff We are advised to NOT judge ALL Muslims by the actions of a few lunatics, but we are encouraged to judge ALL gun owners by the actions of a few lunatics. Funny how that works |

|

#9

|

|||

|

|||

|

__________________

there were three HP ratings on the OM616... 1) Not much power 2) Even less power 3) Not nearly enough power!! 240D w/auto Anyone that thinks a 240D is slow drives too fast. 80 240D Naturally Exasperated, 4-Spd 388k DD 150mph spedo 3:58 Diff We are advised to NOT judge ALL Muslims by the actions of a few lunatics, but we are encouraged to judge ALL gun owners by the actions of a few lunatics. Funny how that works |

|

#10

|

||||

|

||||

|

Quote:

I tried to find some power coat material that would work for exhausts. Obviously there are places that will do it commercially, but I was hoping to find some DIY stuff. No much luck. The various forums show widely different experiences with the high-temp exhaust paint. Some report good results and others show that it flakes off almost right away. True for all brands. I elected to try the VHT Flameproof coating which is supposedly good up to 2000 degrees F. If it works, great, and if not, well I tried. On the exhaust manifold I really tried to prep the surface well by wire brushing, media blasting, washing and degreasing. Same for the turbine housing. The down tube just wire brushing. I guess I'll know soon enough.

__________________

Current Stable

|

|

#11

|

|||

|

|||

|

The test pipe looks great. Did you cut the flanges off the trap ox to use on your pipe or did you make new ones?

|

|

#12

|

||||

|

||||

|

Cut the flanges off the trap cat. The pipe is 180 degree 3" radius mandrel bent 1-7/8 and a 2" two-into-one piece that provided the entry into the turbo flange as well as sleeves for the other joints. Got the exhaust pipe pieces at a local dune buggy shop.

__________________

Current Stable

|

|

#13

|

||||

|

||||

|

Quote:

Cali 617 Test Pipe .

__________________

1983 123.133 California - GreaseCar Veg System |

|

#14

|

||||

|

||||

|

Everything is back together and followed the cure procedures for the high temp paint. Did about 100 miles today including a run up to 3000' to get things nice and toasty. So far so good.

I should note that the valve cover and intake are done in DupliColor 2 part urethane wheel paint, as are the support brackets, etc. All exhaust parts were done in VHT header paint. Looks a lot cleaner in there without the TrapCat.

__________________

Current Stable

|

|

#15

|

||||

|

||||

|

So far so good

Two weeks and a thousand miles doesn't mean a whole lot, but so far the high temp paint is holding up really well. I'm past the point where many posters talked about their paint flaking off almost immediately so I've got my fingers crossed. One lesson learned however is that a higher temp paint should be used on the brackets for the turbo and exhaust as these are starting to discolor on one end from the heat.

__________________

Current Stable

|

|

| Bookmarks |

|

|