|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

Answer

Quote:

OM617 head gasket failure - pictures 1980 240D CRACKED cylinder head + cavitation damage Cavitation Leaky Head Gasket 1985 300TD head gasket repair 1985 300TD head gasket repair OM617 INTAKE and EXHAUST valve guide ID specification Need Definitive OM617 Compression Test Procedure Home Made Special Tools, This is where members can share how they made special tools .

__________________

ASE Master Mechanic https://whunter.carrd.co/ Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 2003 Volvo V70 https://www.boldegoist.com/ Last edited by whunter; 03-13-2013 at 02:13 AM. |

|

#2

|

|||

|

|||

|

Update for you

I found a head at a salvage yard/recycler about an hour and 20 minutes away.

Overall condition of the head appears to be nicer than mine, and included cam, injectors, etc. I looked it over but was focused on the underside of near the valves, and did not recognize anything to be alarmed about so I made the purchase and brought it home. I was kind of in a rush to get back home with it as I had to be to work in less than 2 hours. Yesterday when I was cleaning the gasket material off the face I noticed that the large coolant passages near the outside of the head between cylinder 3 & 4, and the one between 4 & 5 were plugged with an orangish, hard scale. I started poking at it and broke it free, then decided to look very closely at the area around the valves on cylinder 4. I began cleaning with a wire brush on my Dremel, and found a little more pitting on this cylinder versus the others, so I removed the valves from that cylinder and found rust on the intake valve stem, up in the port,and the seat is pitted, and wet with what looks like coolant. Next I wire wheeled around the valve on the face and I think I found a micro crack in about the 2:00 position, but I'm more concerned about the rust up in the port, and on the valve. I called the recycler, and he said to go ahead and bring it back as he wants me to be happy with it and would refund my money. A few minutes later he calls me back and says he had just received a call from a guy in GR that owns a 10 bay service shop that only does German cars looking for a part for a client. While he had him on the line he asked if these old Mercedes diesel heads were known for cracks in the heads. Supposedly, the shop owner told him that every one that came in his shop had small cracks. It was just the way it is with these old MB heads. He said I would probably never find a head without some small cracks in it. They weld the cast and in 20K miles they would come back cracked in the same place, through the welds. The recycler even offered me the guy's name and number to talk to him myself. I told him that I wasn't as concerned about the micro-crack I could see as I was about the scale completely plugging the coolant passage around #4, and the rust up in the intake port on that cylinder and the crack that I couldn't see. If I had recognized the scale in those ports while I was there I would have left it and not purchased it in the first place. He accepted that and said to go ahead and bring it back. BTW, I just wanted to mention that there was no evidence of scale in any other port on that head. None. Very clean in all respects. Am I being too critical and cautious, or am I right in assuming there is a serious issue up in the intake port that can't be seen with the naked eye? Will post the pics of this later, as I need to get this back to them by noon today. Gotta go. Thanks. Rick |

|

#3

|

||||

|

||||

|

Answer

Quote:

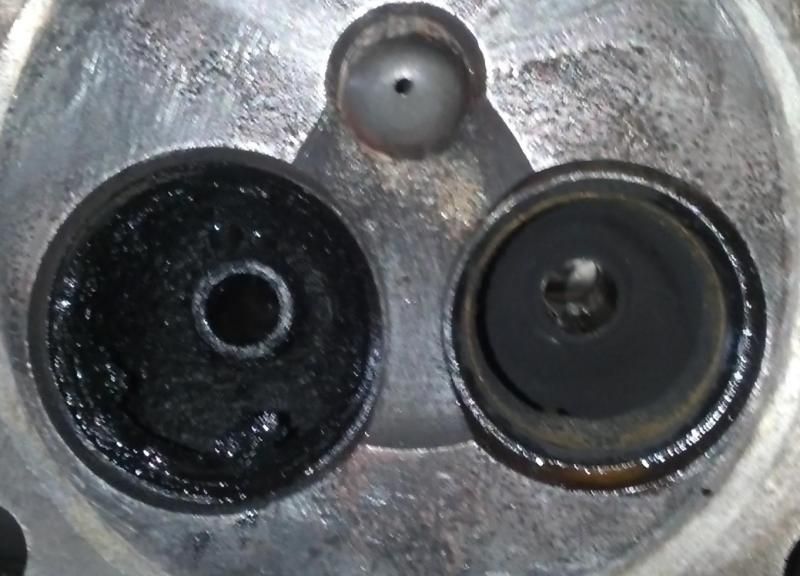

Here is an example of a perfect OM616 cylinder head = no cracks, pitting, or other damage. 1980 240D CRACKED cylinder head + cavitation damage .

__________________

ASE Master Mechanic https://whunter.carrd.co/ Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 2003 Volvo V70 https://www.boldegoist.com/ |

|

#4

|

||||

|

||||

|

Update

Quote:

.

__________________

ASE Master Mechanic https://whunter.carrd.co/ Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 2003 Volvo V70 https://www.boldegoist.com/ |

|

#5

|

|||

|

|||

|

Ford n Benz is running again (sort of)

Here's an update for you all,

After confirming that all the timing was correct, including the injection pump, I still could not get it to start while cranking. Just turned over too slowly to fire. I could get smoke, but that was it. Saturday afternoon my Dad helped me pull start it and finally got it to run. After it was warmed up to operating temperature, I parked it and shut it down. While it was still warm, it started up pretty well. The next day however, no amount of cranking would get it started. Cycled the glow pugs several times. Tried WD40 in the intake and still would not go. As a last ditch effort, I gave it a tiny shot of starting fluid and it finally started. I took it down the road and drove it for 20 minutes or so. I'm getting a lot of smoke at idle, but after it's fully warmed up it will run clear. The smoke is bluish so I'm pretty sure it is oil burning. Getting a lot of smoke from the blow-by also. After getting it as hot as it did when it broke down, is it possible that the rings are carboned up and causing it to smoke now? It didn't before. That has been suggested by someone I know. If so, is there a way to clean the carbon from the rings, like Seafoam, AutoRx or some other type of cleaner? I'm also looking at replacing the starter with a Mean Green Heavy Duty starter which will run me about $349. Are there any other hi-torque starters out there that you would recommend? Thank you for your thoughts and input. Rick |

|

#6

|

||||

|

||||

|

Well I don't think so Rolson. I think it is highly possible the heat took the temper out of your rings, possibly even broke some rings. Cure's out of cans or bottles to undue the stress damage by a major over heating is just NOT a good way to look at the problem. Hate to say so, but I think you need a major engine redo, probably best achieved by replacing the whole engine. Forget your starter upgrade. That is mostly talk also. If your engine is close to being up to snuff, that Bosch starter and a good battery will do the job any day. And remember I said a good battery. It does take a good battery.

__________________

Junqueyardjim Christianity, if false, is of no importance, and if true, of infinite importance. The only thing it cannot be is moderately important. C.S. Lewis 1983 Mercedes W123 240D 4 Speed 285,000 on the road with a 617 turbo, beautiful butter yellow, license plate # 83 240D INDIANA 2003 Jaguar Type X, AWD. beautiful, good mileage, Mom's car, but I won't let her drive it! |

|

#7

|

|||

|

|||

|

Quote:

Honing the bores and re ringing the pistons may work out. It sounds like the typical event of so much overheating the temper is gone out of the compression rings and perhaps to some degree the oil rings. If the engine ran well and burnt little base oil before the overheat One might consider doing it. |

|

#8

|

|||

|

|||

|

Thanks for the input

To all who took the time to answer me back I thank you.

First, I want to remind you that this is a conversion project that mated up a Mercedes OM617 via a conversion kit to a Jeep AX-15 manual transmission, and put them into a Ford Ranger Supercab. Unfortunately, I could not use the original starter. It mounts on the wrong side. I have to use a starter that mounts to the conversion plate alongside the oil pan like the Jeep 4.0L. Therefore, the starter is only 1.4kw and has been a source of frustration since the beginning. I'm around diesel engines on the farm and use them everyday. They all fire right up because the starters are made to handle the compression. The one for the 4.0L gasser Jeep has always been too slow since I took it out of the box. How I wish I could use the original 2.5kw starter that was there to crank this engine over when I got it. That is why I am researching the high-torque starters from Mean Green and elsewhere. I have located a similar Nippondenso starter but they say it's for racing applications on a gas engine where the compression ratio is up to 15:1. Obviously that's still too low for the normal compression of this OM617 engine, but it is much stronger than the current starter that I have. And at only about half the price of the MG starter. As to the rings and oil burning issue: it did not burn oil prior to this major overheat situation. When started cold it used to have very minimal smoke, and then only until it warmed up to a normal operating temperature. After that, it burned nice and clean, even at 220K miles. I am not opposed to honing out the cylinders and re-ringing the pistons. I just don't have a lot of time to do that until winter. Very busy on the farm this time of year. I have looked all around my area several times per week for several months for a replacement engine, and the best I can find so far is one from a recycler with 176K on it for $675. Even if I did swap out the engine for a good one I still have the dilemma of the starter being too small. The good head I found and had new valve guides installed, along with refacing the valves and new stem seals already has over $400 tied up in it. I don't really need a whole engine, just a good block and I have had NO luck finding one of those. Thanks again for your input. I will keep checking in with you. Rick |

|

| Bookmarks |

|

|