|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

603 Fan Clutch Bolt Rounded Out - Now What...

The SDL is in need of a water pump (bearings only slightly better than craptastic) and step #2 (after pulling back the fan shroud) is to undo the bolt holding the fan clutch to the water pump assembly.

Sounds great on paper, not so easy 30+ years later. Long story made very short, I have a pulley holder and the special 8mm "screwdriver" bit to remove the bolt. It's set in concrete or something, clearly has never been removed and instead of the bolt unthreading, the stupid head rounded out. Now what... Can I get the water pump out with the clutch and fan still attached? I intend to replace the fan clutch and blade with those from a 606, so I don't mind drilling out the bolts or destroying them to get the pulley removed once I get the pump out. I want to avoid draining the A/C and removing the condenser. The system is currently gas-tight and I'd prefer not to mess with any of that if possible. I have no problem pulling the radiator, it's only a 10 minute job. Suggestions are always appreciated.

__________________

Current stable: 1995 E320 157K (Nancy) 1983 500SL 125K (SLoL) Gone but not forgotten: 1986 300SDL (RIP) 1991 350SD 1991 560SEL 1990 560SEL 1986 500SEL Euro (Rusted to nothing at 47K!) Gone and wanting to forget: 1985 524TD 167K (TotalDumpster™) [Definitely NOT a Benz] |

|

#2

|

||||

|

||||

|

Unfortunately the 124 (and I’m pretty sure the 126) has a permanent upper cross brace. (They changed this to a removable style in the W210 and it makes radiator/condenser replacement soooo much easier) From what I remember fixing up my 124 a few years back you can’t get the radiator out without removing the fan.

It may take some serious creativity to get around the fan/WP assembly to remove the WP bolts, with the fan in place. I would highly recommend slipping a piece of cardboard on the back side of the radiator before starting lest you slip and hurt the radiator.

__________________

The OM 642/722.9 powered family Still going strong 2014 ML350 Bluetec (wife's DD) 2013 E350 Bluetec (my DD) both my kids cars went to junkyard in 2023 2008 ML320 CDI (Older son’s DD) fatal transmission failure, water soaked/fried rear SAM, numerous other issues, just too far gone to save (165k miles) 2008 E320 Bluetec (Younger son's DD) injector failed open and diluted oil with diesel, spun main bearings (240k miles) 1998 E300DT sold to TimFreeh 1987 300TD sold to vstech |

|

#3

|

||||

|

||||

|

I don’t think you can get to all the water pump bolts with the pulley in place. I think you can get to all the water pump housing bolts that go transversely into the block. Then deal with the mess on a bench. You’ll need a new gasket between the water pump housing and the block. Possibly a new o-ring for the cabin heat return line. It’s the same o-ring as the cabin heat supply line on the far end of the cylinder head.

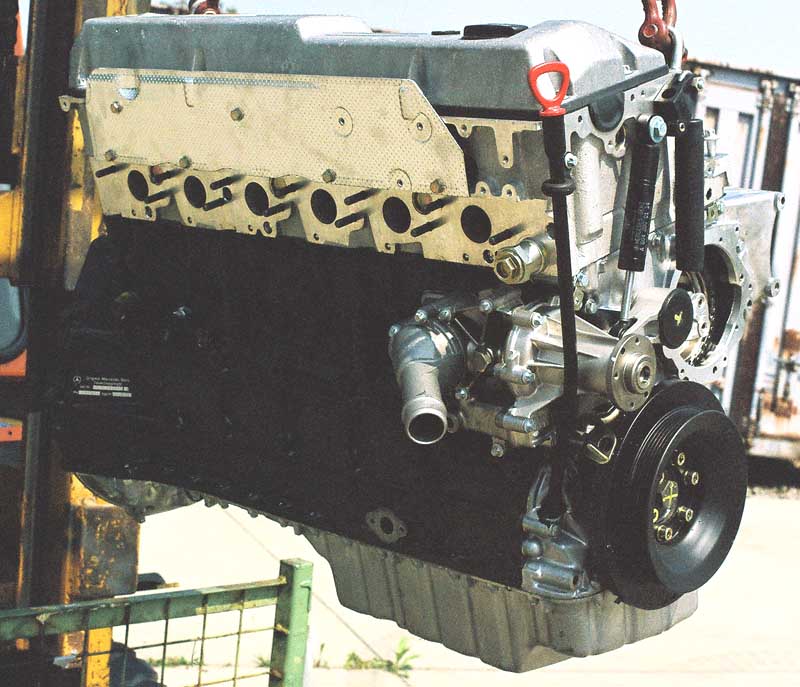

Here’s the housing on the block -  Here’s the housing with water pump -  Sixto 98 E320s sedan and wagon |

|

#4

|

|||

|

|||

|

File two flat sides into the bolt head, and turn it out with a wrench?

__________________

1998 E300 turbodiesel America's Rights and Freedoms Are Not The Enemy! |

|

#5

|

||||

|

||||

|

Quote:

The bolt is sunk deep and flush into the inside of the fan clutch, also the fan clutch fins will get in the way I think. So I don't know if he could grab enough of the bolt to get it out. Hopefully I'm wrong.  Honestly I'd just find a friend or someone with a die grinder or cut off tool too cut off the tail end of the water pump. Or is that too extreme?

__________________

1998 Ford Escort ZX2 5 speed - 279,000 miles My Daily 1992 Mercedes 300D 2.5 202,000 - Pure junk 2000 Mercedes E320 Black - 136,000 miles - Needs repair Don't forget to grease the screw and threads on the spring compressor. |

|

#6

|

||||

|

||||

|

Get radiator and AC condenser out of the way so you can hammer in an oversize XZN bit then use an impact gun. A lot of work but I don't see another way that's more palatable.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#7

|

||||

|

||||

|

I would use an easy out.

__________________

Satan creates nothing: he only ruins everything. He does not invent: he tampers. And his followers are no different ~ Archbishop Carlo Maria Viganò |

|

#8

|

||||

|

||||

|

Can you break the fan clutch apart with a big chisel or air chisel? 2nd idea would be remove radiator and plug weld some flat stock or a nut onto the bolt if you can get a mig torch in there, or a bendable stick electrode like some Messer 80t. Any way to finagle an air chisel onto the inside edge of the bolt and shock it? Maybe a custom designed chisel. With the radiator out of course.

__________________

Brian 87 300Dturbo 180K #14 head still running R-12 SOLD 12/2017 02 F350 Powerstroke 180K 05 Chevy Express 1 ton w/Royal Utility box 120K 08 Infiniti FX-35 40K 15 Golf Sportwagen TDI 35K 10 Sprinter 3500 chassis with a Class A Winnebago on it. 56K |

|

#9

|

||||

|

||||

|

Remove the bimetal strip then grab the bolt with a socket style extractor.

Sixto 97 E320s sedan and wagon |

|

#10

|

|||||

|

|||||

|

Quote:

Quote:

Quote:

Quote:

Quote:

Keep the ideas coming, there's definitely some viable options here. Part of what's hampering my own thought processes is lack of visibility. That fan shroud and the lack of any way to get a good line of sight on the front of the engine is really a hinderance. I'm strongly considering the later 2-piece fan shroud from the 350, but that will be a function of budget rather than raw necessity.

__________________

Current stable: 1995 E320 157K (Nancy) 1983 500SL 125K (SLoL) Gone but not forgotten: 1986 300SDL (RIP) 1991 350SD 1991 560SEL 1990 560SEL 1986 500SEL Euro (Rusted to nothing at 47K!) Gone and wanting to forget: 1985 524TD 167K (TotalDumpster™) [Definitely NOT a Benz] |

|

#11

|

||||

|

||||

|

Cut the fan shroud in half. You can easily splice it back together with sheet metal and self tapping screws. Use a hot knife where you can't use a saw.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#12

|

||||

|

||||

|

The bimetal strip is held by spring tension and a dab of RTV. Mind the pin under one end of the bimetal strip.

Sixto 98 E320s sedan and wagon |

|

#13

|

||||

|

||||

|

For future reference, rounding out an allen like this usually is a result of not cleaning the dirt out of the recess thus not getting full depth engagement of the allen flats inside the bolt head. If you have that clean and full engagement of the allen you should either break the head off or get the bolt out.

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#14

|

||||

|

||||

|

Rounding out an Allen head can have other causes such as using a cheap out of tolerance bit with bad metallurgy. Allen is not the best to use in high torque critical fasteners. I'd replace it with an XZN fastener which is much less likely to round out.

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#15

|

|||

|

|||

|

One thing you could try is heat: insert an allen socket in the bolt head. Heat the socket with a propane torch. If you're careful, you can put plenty of heat into that bolt without collateral damage.

I agree with Tom, the main reason socket bolts round out is debris. XZN's are better for high torque applications, but just as likely to gall if they aren't clean. |

|

| Bookmarks |

|

|