|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

Pre-Chamber Ball Came Loose

1974 240D, W115, OM616.916

I recently moved back to New Mexico from Utah. As part of the process I drove the '74 from Salt Lake City to Albuquerque, about 600 miles. During the trip the car started nailing, and it got worse quickly in the last 30 miles. When I got home I cracked the fuel lines and isolated #4 as the culprit. I've experienced nailing before but not like this. It was nailing at high RPM, under power while going down the road. I did not notice a decrease in power, and the engine did not over heat. Some history: 3 years ago, before moving to Salt Lake and driving the car there, I had all four injectors rebuilt by a local ABQ shop I trust, Central Motive Power. Looking at the receipt it is not stated explicitly that nozzles were replaced, but I assume they were since the total for all 4 injectors was $340. I also re-timed the cam using a offset key, and re-set injection timing to compensate for a little bit of chain stretch. Then we moved to Utah, and the car did fine during that 600 mile trip and also for the little bit of use it got in SLC. It ended up sitting in storage for most of our time there, driven only 500 miles or so during the 3 years. I used diesel stabilizer and Biobor in the fuel to prevent problems related to fuel storage. So today I spent a little time taking things apart to see if anything was obviously wrong. I removed the injector and found that the nozzle needle's tip was broken off:  I looked down into the pre-chamber to check on the ball, and sure enough it was busted off and floating around in there. I also noticed that the tip of the chamber was bulging out a little:  And here is the tip of the glow plug (glow system converted to pencil type plugs):  At this point I assume the nozzle needle broke off allowing fuel into the chamber out of time thus burning up the ball and glow plug and causing the chamber tip to bulge. Replacing the damaged parts with good ones should get the engine going again, right? I need a pre-chamber - does anybody have one laying around that I could purchase? It's the flat tipped chamber for NA engines I need, not the rounded tip like you find in the 617 turbos. Part of me also wonders what else could be at play here. Injector damaged by water in fuel during storage? Did I set injection timing too far advanced (I've set IP timing before with no troubles)? Anything else I should be looking into here? Thanks!

__________________

- Greg - 1973 220D, The Prodigal Benz 1974 240D |

|

#2

|

|||

|

|||

|

While you have the injector out I would probably check the compresson to make sure it did not hole a piston or something. Did it seem like it was only running on 3 cylinders or did it run normal but just have the nailing.

|

|

#3

|

||||

|

||||

|

I'll have to borrow, buy or rent a tool set for checking compression but that is a good idea. The engine ran fine despite the nailing. No noticeable loss of power and no smoke, no loss of engine oil. After pulling the pre-chamber I looked down onto the piston top and did not detect any damage where I could see.

__________________

- Greg - 1973 220D, The Prodigal Benz 1974 240D |

|

#4

|

||||

|

||||

|

You could remove the old Nozzle and see if it is a Bosch Germany or a Bosch India Nozzle and you will know if they replaced the Nozzles or not.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#5

|

||||

|

||||

|

Are they marked? I've never gotten myself into the guts of an injector. I'll check it out. Thanks for the suggestion.

__________________

- Greg - 1973 220D, The Prodigal Benz 1974 240D |

|

#6

|

||||

|

||||

|

Quote:

The picture is just to show where the info is located. You need to remove the Nozzle Nut to get the Nozzle out. In one pic the square box has the 2 parts of the Nozzle and the green arrow points to a part that if you don't get it installed in the correct orientation will break off part of the Nozzle.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#7

|

||||

|

||||

|

I took the injector apart this morning and found that the nozzle is a Bosch India unit. Got about 2000 miles out of it, as well as a bum pre-chamber and glow plug.

Did the busted needle cause all of this? Or was there some other factor involved in the needle tip breaking off? Found used pre-chambers for sale and just ordered one from our friend Kent.

__________________

- Greg - 1973 220D, The Prodigal Benz 1974 240D |

|

#8

|

||||

|

||||

|

Quote:

We were typing at the same time! Thanks for your response. I'm taking the injector down to the shop this morning to have it rebuilt again. RE: Indian nozzles - I had all 6 injectors in the '96 rebuilt with Indian nozzles a year or so back. I've not had any trouble with them. In fact, the car runs really well. But, I know, it only takes one bad one to ruin your day (or your pre-chamber).

__________________

- Greg - 1973 220D, The Prodigal Benz 1974 240D |

|

#9

|

||||

|

||||

|

Quote:

I forgot to mention that there is different types of Prechambers. There is a number on the flange of the prechamber that needs to match up with the replacement one.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#10

|

||||

|

||||

|

Quote:

From what I can see online there are early style flat tipped ones for NA engines with the old style large diameter loop glow plugs (like mine), and there are flat tipped ones for NA engines that have a smaller hole for the pencil type plugs (OM616 in W123s, maybe NA 617s too). And then there are the rounded tip ones used in turbos. Not sure if rounded tip ones were ever used in NA engines. S-K also produced pre-chambers for these engines. I have several of these I got from U-Pull engines. The S-K chambers have a polished steel heat shield riveted into them, they don't come out. These are stamped "S-K" on their sides. FWIW the fellow I spoke with at the injection shop thought my busted nozzle needle problem had something to do with the car sitting for longer periods without being driven, gummed with fuel, etc. Maybe so. Maybe not. Thanks for the heads up. When I receive my "new" one I'll be sure to compare it closely to the others to make sure it is indeed the same.

__________________

- Greg - 1973 220D, The Prodigal Benz 1974 240D |

|

#11

|

||||

|

||||

|

Update

This project has been on hold for a bit because I donít like working on cars in the cold if I donít have to! But I have learned a few things along the way, like about the variety of pre-chambers used in N/A OM615/616/617 engines. Iíve also deepened my understanding of how the pneumatically governed injection pump works to meter fuel, and how one should not go mucking about with governor springs and shims willy nilly. More on that later . . .

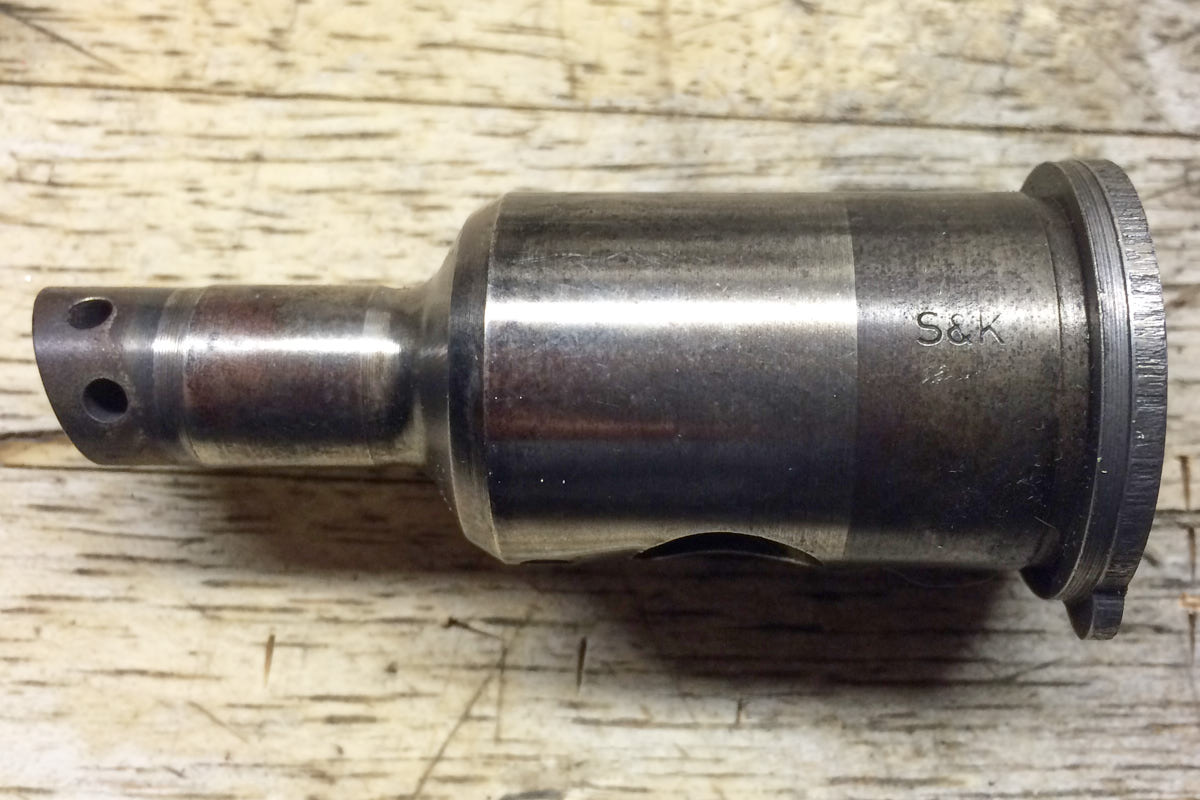

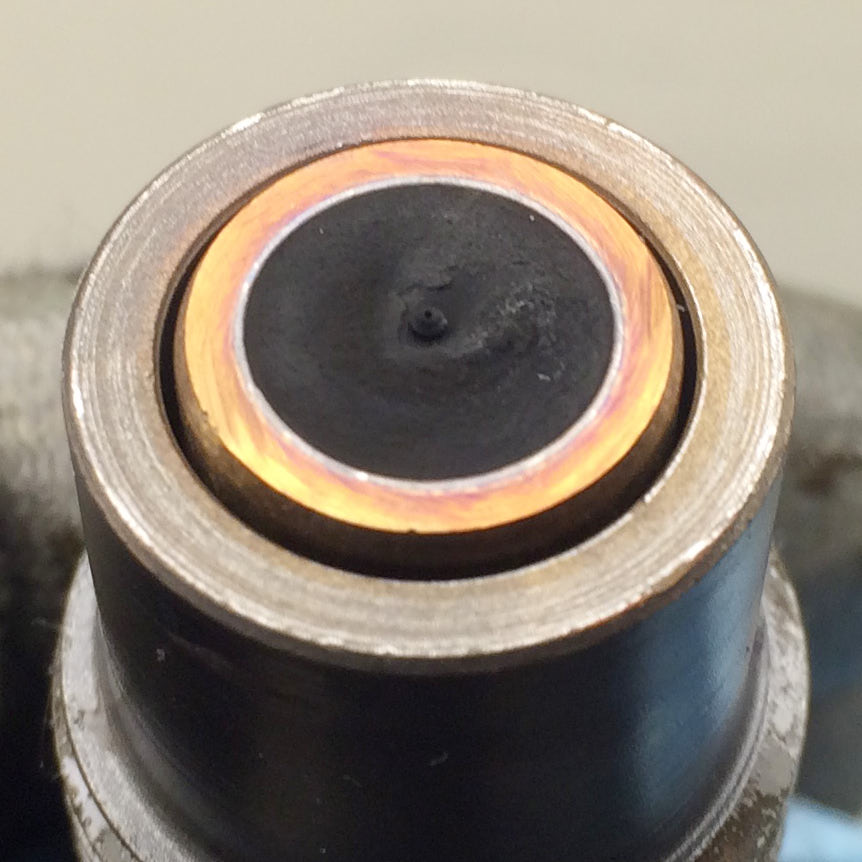

In the meantime Iíll pick up pretty much where I left off, with my hunt for a pre-chamber that matched the existing set in my carís engine. I had ordered a used pre-chamber from Uncle Kent because none of the ones in my stash were a match for the engineís. When it arrived it proved to not be a match for the engine but was a match for some of those in my stash, made by S&K. This image shows the obvious differences:  My existing chamber is on the left, and the S&K I got from Kent on the right. I originally assumed the ďMADE IN GERMANYĒ pre-chamber was made by Bosch, but apparently Bosch didnít make pre-chambers. Anywho, I returned the S&K to Kent and continued the hunt. After trying a few different suppliers and not finding what I wanted I called Metric Motors and talked to Mike about my situation. Two things important came from this conversation: (1) I learned more about pre-chambers and who made them (Laso, Febi, S&K, and perhaps others); and (2) I learned about the possibility of a lean running condition being the root cause of my injector and pre-chamber troubles. Well, actually three important things resulted from this conversation, the 3rd being I scored a NOS pre-chamber that is a match to the ones in my engine. Thank you Mike and Metric! Those folks are always helpful. Before moving on I want to cover the varieties of pre-chambers Iíve seen in the time Iíve been messing around with W115 diesels with OM615/616s in them. The photo above shows my ďMADE IN GERMANYĒ chamber of unknown make, and the S&K that seems to be more common. In my stash I have an example of a third type of pre-chamber, by S&K, that appears to have a heat shield permanently attached. See this:  That steel disc does not come out without a fight. It appears to be riveted in. I canít imagine this design working with the normal heat shields we replace every time we install our injectors. This chamber is stamped ďS&KĒ on the side, just like the other other S&K chambers Iíve seen that donít have this steel disc in them.  Going back to the possibility of a lean condition I pulled the remaining injectors so I could have a look at their nozzles and also to get a peak down into the pre-chambers to check on their balls. I used a screw driver to pry on the balls and thankfully found all of them tight. The injector tips look good, but itís obvious they got a little hot:  Notice the nice dark straw color the nozzle took from the heat, indicating about 500 degrees F. Notice also the relatively small amount of carbon build-up. I showed the injectors to Joe at the injection shop and he thought they were fine, that exposure to 500 degrees F was not enough to alter their temper to a harmful point if at all. The coloration of the nozzles and the lighter-than-normal carbon build up lead me to believe the engine was indeed running a bit lean and a bit hot in the pre-chambers. My original theory was that the #4 injector nozzle tip broke off and the resulting lousy spray pattern damaged the pre-chamber. Now I donít believe that. Rather, I think my problem started with the lean running condition that caused things to get hotter than normal in the pre-chambers. #4 chamber ball came loose and in the process of bouncing around knocked the tip off the nozzleís needle. Or some variation of this process. Fortunately for me this was as far down the slippery slope as it went. The next phase probably would have had something to do with the tip of the pre-chamber coming off and causing mayhem down in the combustion chamber. Witness that bulging tip shown above. So how did my engine end up running lean? And what does that have to do with mucking around with the pneumatic governor? Long story short is that I got curious about how the governor in this engine was setup, so I removed the housing to get at the spring and shims. I have another IP from a U-Pull car I grabbed years ago to have something to play around with. I also pulled the governor housing off this IP and removed the spring and shims to compare to those from the engine in the car. And then things sat for a bit before I put it all back together. Well, you can probably see where Iím going with this - Iím pretty sure I mixed up the springs and/or shims between the IPs thus throwing calibration off a bit to the lean side. Coming to this point I realized that the IP was going to have to come out and be taken to the shop for calibration. We have a great Bosch shop here in ABQ. The foreman, Joe, is old school, and knows these vintage M-B Bosch pumps well. I had him clean up, re-seal, and calibrate the pump for me, and the cost was a totally reasonable $450. I wanted to reseal the pump anyway because itís been a leaky mess. The injector elements were all fine and didnít require replacement, which saved some money compared to a full-on rebuild. Hereís the dirty pump post-removal:  As things stand now Iíve got the IP sitting on the bench ready for install but Iím a wimp when it comes to wrenching in the cold. I need to order the gasket that fits between the IP and engine, plus a few other tidbits for the project. Iíll update again when I get it back together and running, and have had a chance to verify that the engine is still OK.

__________________

- Greg - 1973 220D, The Prodigal Benz 1974 240D |

|

#12

|

|||

|

|||

|

Just a couple notes during my lunch break...

Running lean in a diesel means running cooler temps, its the opposite of a petrol engine (unless its running lean of peak) The prechambers changed during a few years for emissions reasons I believe, then changed back (I think, don't really know) so that will be why there is a difference. It's not a heat shield

__________________

1978 300D, 373,000km 617.912, 711.113 5 speed, 7.5mm superpump, HX30W turbo...many, many years in the making.... 1977 280> 300D - 500,000km+ (to be sold...) 1984 240TD>300TD 121,000 miles, *gone* 1977 250 parts car 1988 Toyota Corona 2.0D *gone* 1975 FJ45>HJ45 1981 200>240D (to be sold...) 1999 Hyundai Lantra 1.6 *gone* 1980s Lansing Bagnall FOER 5.2 Forklift (the Mk2 engine hoist) 2001 Holden Rodeo 4JB1T 2WD |

|

#13

|

||||

|

||||

|

Quote:

Quote:

My '74 240D came to me with with all four of the pre-chambers having that steel disc in them, and no removable heat shields like we are familiar with. I drove it for a while before getting into the injection system. When I did get around to removing the injectors I noticed the lack of removable heat shield and also noticed that the nozzles sealed up against those discs just fine, no signs of compression leakage. Still, I swapped in the set of "MADE IN GERMANY" chambers I had on the shelf so I could use the removable heat shields as usual. I also pulled injectors and pre-chambers from a U-Pull engine that had these steel discs in them. The injectors were installed using the usual removable heat shields on top of the steel discs. After pulling the injectors I found excess carbon in the space between the nozzles and chambers. The removable heat shields had to be dug out of the carbon mess. Seemed to me they weren't sealing very well when used in conjunction with the riveted in steel discs. I can't be the only fellow to have stumbled onto these oddball S&K pre-chambers . . .

__________________

- Greg - 1973 220D, The Prodigal Benz 1974 240D |

|

#14

|

||||

|

||||

|

I pulled a set of 4 S&K prechambers out of my '79 240D. After I cleaned them in an ultrasonic cleaner, it doesn't look like the bottom disc is riveted in. I can't really see any kind of seam on mine.

I did run the heat shields as well, with no real issues to speak of. Heat shields were in when I pulled my old injectors out, judging by the rest of the car I would not be surprised if the injectors had never been out before.

__________________

Milan Brown 1979 240D, rebuilt OM617.952 turbo diesel, rebuilt 722.315 transmission (my only daily driver) Instagram: @maximed93 |

|

#15

|

|||

|

|||

|

The amount of fuel in determines the power. With a diesel. The air ingress per stroke may remain pretty constant. Per power stroke. I have having a bit of an issue with this.

For example in my city driving I would have a much leaner or lesser amount of fuel injected than when at speed. Now an injection pump out of calibration might inject a cylinder earlier creating more heat. Than intended in design. Setting the injection pump timing uses only the first element for calibration. There is not much carbon buildup. Although with so few miles on the nozzles that is pretty normal I thin. k. About the only way I could see overheated nozzles would be burning a tank of gas. The amount of air ingested is not critical as when a diesel cylinder burns there is oxygen left over. Unless design limits are exceeded I suspect. The only other thought is kerosene is too expensive to use for winter fuel. Various suppliers may be using some chemical that is also increasing heat as well.. It may have been a pretty long time since kerosene has been used. There are many things fuel suppliers probably do today. Gives me something to think about. Lean only applies to gas engines I thought. Last edited by barry12345; 01-25-2019 at 04:42 PM. |

|

| Bookmarks |

|

|