|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

IP timing adjust (turning) tool

FSM 07.1-114 has a procedure and describes a special tool (with a lousy pic) that allows you to rotate the IP and adjust the timing with the engine running. Has anyone built a similar tool on their own? The tool is NLA and was expensive (around $500) when it was available.

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#2

|

||||

|

||||

|

probably just an expensive turnbuckle

|

|

#3

|

|||

|

|||

|

They show some amazing tools in the FSM, like the hypothetical (?) cylinder liner installation tool. Some did exist, but I wonder how many dealers actually bought them. Same thing in my old Mopar FSM's, all kinds of special tools that most resourceful people can find an easy way to do without.

|

|

#4

|

||||

|

||||

|

Looks like a big open ended spanner to me.

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#5

|

||||

|

||||

|

Looks like the spanner anchors against 2 cylinder head bolts via an adjuster. I would like to know how that plate is attached to the head bolts. Pic in FSM is useless.

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#6

|

||||

|

||||

|

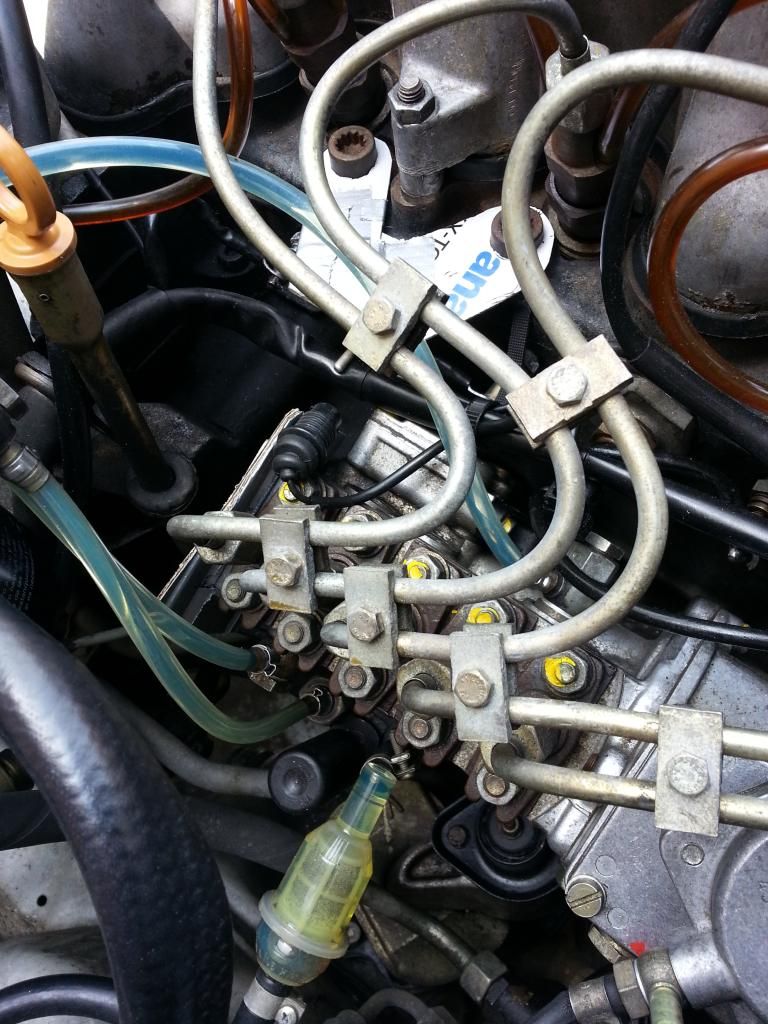

Original pictures

Do these help?

These are from the German FSM where the pictures are a bit clearer

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#7

|

||||

|

||||

|

Quote:

I think it is expensive partly because part of it is left hand treaded or there is a Ball and Socket on one part. I have a picture of the whole Tool Some where but all I could find is the one in the pictrue which is 1/2 of the complete tool. The Heat Bolts fit in to the Holes and not shown there is a Clamp that clamps to the front of the Fuel Injection Pump and attaches to that slotted end to the Right of the Pic. Either on our Forum or on Benzworked one of the Member made something that functioned the same. When you move the Fuel Injection Pump it may be possible to tear the Gasket. If you plan to run Engine with the IP loose and use the Tool to rotate it that increases the chance of the Gasket tearing.

__________________

84 300D, 82 Volvo 244Gl Diesel Last edited by Diesel911; 06-04-2014 at 06:12 PM. |

|

#8

|

||||

|

||||

|

Those are good pics Stretch, does not show details of the piece that attaches to the head bolts but I had the right idea, I made these templates out of card board before looking at Diesel911's pic.

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#9

|

||||

|

||||

|

I think it is expensive because it is for a Mercedes!

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#10

|

||||

|

||||

|

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#11

|

||||

|

||||

|

If you oiled both sides of the gasket you could probably slide stuff around without breaking it

__________________

$60 OM617 Blank Exhaust Flanges $110 OM606 Blank Exhaust Flanges No merc at the moment |

|

#12

|

||||

|

||||

|

I was thinking the same thing. After loosening the IP mounting bolts, spray the gasket all round with penetrating oil and let it soak a while before turning the IP. I would hate to get an oil leak after a timing adjustment and have to pull the IP. A gasket is a bad design IMO, much better if it was an o-ring.

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#13

|

||||

|

||||

|

Quote:

__________________

$60 OM617 Blank Exhaust Flanges $110 OM606 Blank Exhaust Flanges No merc at the moment |

|

#14

|

||||

|

||||

|

Or just try it with that spray on Hylomar gasket sealer - stops the leaks and "might" give you a bit of lubrication for the twisting.

I thought the point of this tool was to give you a little bit more control over the positioning of the IP - I don't think lubrication is going to change much. This special tool reminds me of a helper tool I have for adjusting belt tension on alternator belts. It is essentially an extendible stick that you wedge between the alternator and the engine block. There's a screw thread in the "stick" that makes it extend or contract.

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#15

|

||||

|

||||

|

Quote:

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|