|

|

|

|

|

|

|

|

|

|

|

#31

|

|||

|

|||

|

The first post in the thread was on 12/20/2009 so yes it has been that long.

The first request for pictures was on 2/28/2010 so that was only a little over 4 months ago. See why it's easier to keep it in one thread?

__________________

1987 300TD 309, xxx 2.8.2014 10,000 mile OCI Be careful of the toes you step on today, as they may be connected to the ass you have to kiss tomorrow. anonymous “Be who you are and say what you feel, because those who mind don’t matter, and those who matter won’t mind.” Dr. Seuss |

|

#32

|

|||

|

|||

|

It does appear that a few people are very very keen to see pictures so here's one of the broken brackets.

My car was built in Germany for the Japanese market, curiously it is LHD, and was imported to Canada in 2009. It has about 120,000kms on it, does 40mpcanadiangallon, and runs beautifully (apart from the occasional broken bracket!)

|

|

#33

|

|||

|

|||

|

Right across the bolt hole..

You might want to look in the parts manual... or even if not shown there.... place a grade eight washer under the bolt... Can you lay it on a scanner and send that scan ? Or get really close up with the camera in good light ? What exactly attaches to the other end of that bracket ? Could unwanted movement there cause this to break.... at the point where the bolt will not let the upper part of the bracket move ?

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/diesel-discussion/10414-help-i-need-check-stretch.html http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#34

|

||||

|

||||

|

i have a theory... maybe the bolt head was just a tad too big and was propped up against the curve of the bracket and was pushing down on it. soooo, tightening was enough to give it undue stress at that point... which eventually caused the failure...

from the marks it seems the bolt was tightened up real good... since there is a rubber bushing in there maybe its a bad idea to overtighten anyway... AFAIK, tiny fractures DO cause bigger fractures when it comes to metals... still doesn't explain the breakage above the bolt hole though... (c holmes') speaking of overtightening... can the angle of the bracket be altered(pivoted) off axis when tightening(overtightening) the lower bolts for the swaybar? imagine the swaybar bracket...angled not perfectly perpendicular to the pushing force of the swaybar, negating any "flex" that the flat part has to offer... something's gotta snap right?

__________________

85 190E 2.3(SOLD) 86 230E (-->300D) sold 87 300D (-->300TD) sold 68 250S w/ a 615 and manual tranny (RIP) 87 300TD (SOLD) 95 S280 "The KRAKEN" (Turbo 2.9 602 transplant) traded 86 190E 2.3... current project |

|

#35

|

||||

|

||||

|

Question

Quote:

W210 DANGEROUS FLAW please read (crosslinked in post #1 to all on topic data) W210 DANGEROUS FLAW please read (crosslinked in post #1 to all on topic data) W124 SPRING PERCH = Front Spring Bracing Have a great day.

__________________

ASE Master Mechanic https://whunter.carrd.co/ Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 2003 Volvo V70 https://www.boldegoist.com/ |

|

#36

|

||||

|

||||

|

I gotta agree with Whunter here, that is a stress break, and it's on the bolt hole, so the two ends of the bracket are pivoting. something on your bracket is moving! if you can get the car up on a lift, and get some pictures of the underside I may be able to assist your diagnosis. if not, eventually I will have my 87TD on a lift and I can see what could be causing it to stress fail.

look carefully at the picture. you will see wear marks on one side of the bolt hole from the bolt head, but none on the other! it's moving! Last edited by vstech; 07-12-2010 at 10:00 AM. |

|

#37

|

|||

|

|||

|

How about only one end moving ?

that is a long torque arm on the section not between the two holes bracketing the grommet which holds the sway bar... What does that attach to way off down there ?

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/showthread.php?threadid=10414 http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#38

|

||||

|

||||

|

the long end is free from movement marks, my bet is the short end is moving.

|

|

#39

|

|||

|

|||

|

So describe the way that part can move with a solid rubber grommet and a sway bar inside it.....

BUT that other ' handle' ...whatever it is attached to... if that moves then the break happens exactly where the working part of the bracket is secured to the firewall.... Show me those ' movement ' marks and why they could not have been produced by the movement of the long arm....

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/showthread.php?threadid=10414 http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#40

|

||||

|

||||

|

that's why I want pictures on the car... I have no idea how it attaches to the car or what could move. just that one side of the broken part has marks all over it from the bolt head, and the other side does not.

|

|

#41

|

||||

|

||||

|

Quote:

.

__________________

1983 123.133 California - GreaseCar Veg System |

|

#42

|

||||

|

||||

|

Not sure if this will help, but here goes.

__________________

Rick Miley 2014 Tesla Model S 2018 Tesla Model 3 2017 Nissan LEAF Former MB: 99 E300, 86 190E 2.3, 87 300E, 80 240D, 82 204D Euro Chain Elongation References |

|

#43

|

||||

|

||||

|

I just saw a w124 today and wished I had a camera to take some pictures. But I have say that is one "F"ed up design that Mercedes decided to choose.

The bracket just hangs down like an upside down "L" and the swaybar attaches to the end. No body attachment except at the top. Not much strength there and I can see how it would crack in half at the bolt holes. Your better off creating some new units out of some pipe stock.  .

__________________

1983 123.133 California - GreaseCar Veg System |

|

#44

|

|||

|

|||

|

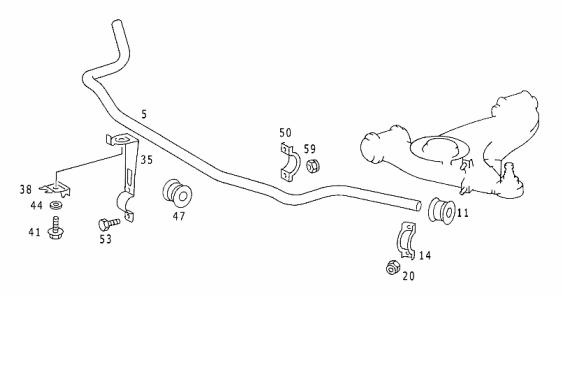

Ok,,,what the heck does 38 and 41 go in to ?

The battery box ?

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/showthread.php?threadid=10414 http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#45

|

|||

|

|||

|

#41 bolts into a captive thread in the chassis.

I do have another theory for C Holmes: Bracket 14 is smaller than bracket 50, and assembling using 14 instead of 50 will prevent the clamp from fully closing, and accelerate fatigue in the bracket35. (Don't ask me how I know!) Leathermang's suggestion to put a washer under the top bolt53 (there are 2 bolts 53, the parts picture is not very clear on that area.) is a good one, as it would spread the load and support the bolthole. Brackets 35 and 50 must be bolted together solidly, no gaps. Quote:

|

|

| Bookmarks |

|

|