|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

Can you use two small bolts, nuts, spacers and washers like on top?

.

__________________

1983 123.133 California - GreaseCar Veg System |

|

#2

|

||||

|

||||

|

Or B7 all thread with nuts at each end. I'd put some gussets in there in the direction of car travel to "stiffen" it up front to back.

__________________

Jim |

|

#3

|

||||

|

||||

|

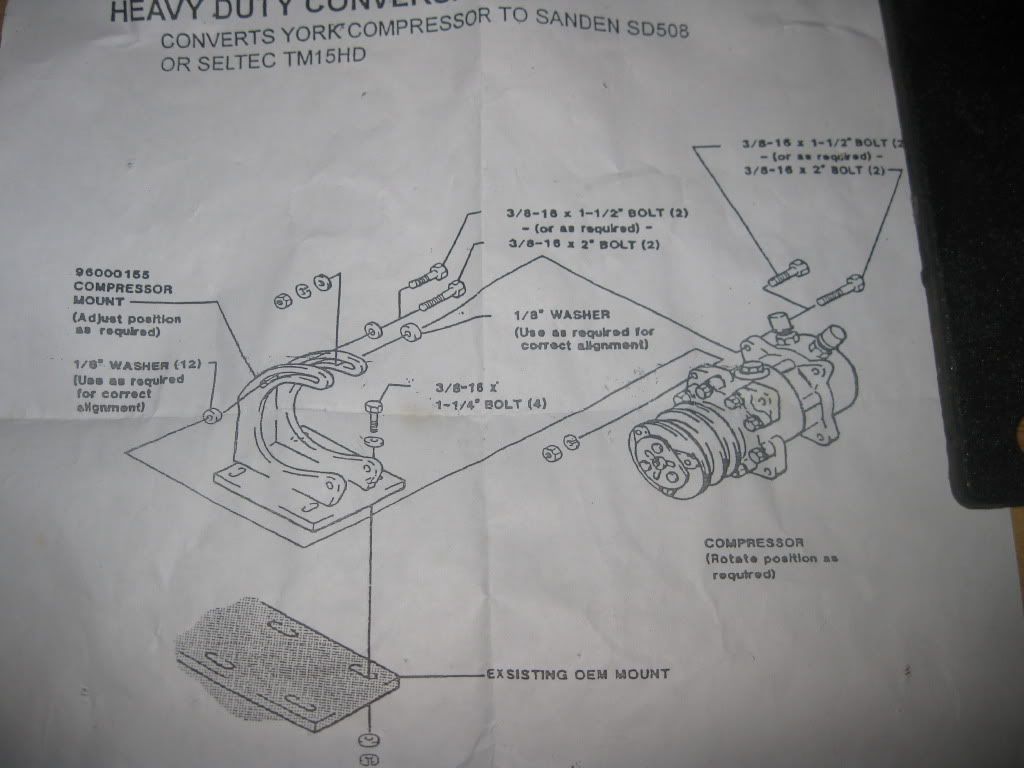

If I posted on weldingweb they would have seizures from overexposure to AWESOME!

Yea, I almost took it some where to be welded but I was worried about warpage. Believe it or not it did shift from the position of the tack welds  I had to move around to avoid too much distortion and you have to get it HOT to get decent penetration. The job really calls for a bigger machine than mine and better skill than I possess. This is how the bracket is supposed to be used:  I just figured the single bolt would be stronger but I may look at using some welded nuts or threaded rod. A slightly shorter bolt may work as well... Some pics: This is it with the manifold tubes and the power steering pump in place.  I think I would be wasting my time even trying to fit the oil cooler lines  Without power steering pump:  Bench shot:  Those fittings are supposed to be everything I need to rig this stuff up. You can see how much clearance you lose with the 90 deg fittings off the compressor. I rechecked and it looks like the oil cooler lines WILL clear. Thank God...

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD Last edited by 1980sd; 07-06-2011 at 02:06 AM. |

|

#4

|

||||

|

||||

|

Fooled with it a little tonight:

I got an FK head because I hoped the service valves would be accessible but I decided to put 134a manifolds on it as well. Everything clears the oil lines but plain 90 deg manifolds would allow the lines to point either direction with plenty of room. The way it is now the 134a ports prevent them from being positioned the right way. (Hi to the front/lo to the rear.) There is still room to turn them around but it would put the hi port directly under the power steering pump and I don't think I could access that port with a gauge manifold. It's tight in there but not as tight as the pic makes it look. I mainly did it like this so it would be easier to try out both refrigerants if I want too. Anyway... So far so good. I need to rig up an oil cooler line bracket on one of the compressor arms that will allow enough clearance to get to the tensioning bolts. Front view:

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD Last edited by 1980sd; 07-06-2011 at 11:41 PM. |

|

#5

|

||||

|

||||

|

Oil cooler lines bracket:

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD |

|

#6

|

||||

|

||||

|

Just in time for fall!

http://www.youtube.com/watch?v=G2XnY8lmC2o I was manually switching the compressor. "Band on the run" was playing on the radio...

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD |

|

#7

|

||||

|

||||

|

Update:

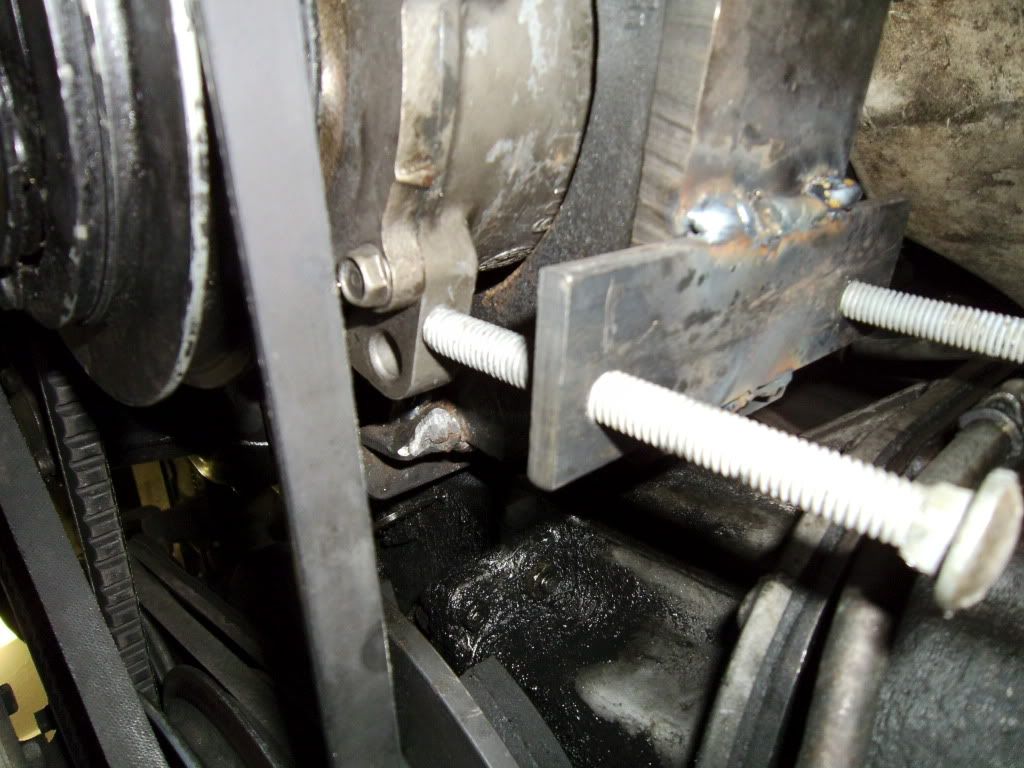

This was the old system of holding belt tension:  Seems the bolts weren't enough to keep the belt tight. It even loosened after driving about 120 miles without the compressor engaged  Jim, AKA engawork looked at it and suggested bolts to hold tension here on the bottom:  He actually suggested welding lugs on the side of the bracket with through bolts but I drilled/tapped a plate and welded it on. I need to replace the bolts with shorter ones and install lock nuts. But I think this'll solve my loose belt problem. Before it was near impossible to hold tension on the belt AND tighten the adjustment bolt... I'm going on a 400 mile trip tomorrow and I'll test it out with the compressor off. Wish me luck!

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD |

|

| Bookmarks |

|

|