|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

|

|

#1

|

||||

|

||||

|

Introducing my timing light - injection timing- digital RIV method- bench test

The FSM procedure 07.1-108, Checking injection timing (begin of delivery) with digital tester (RIV method) has a diagram which shows a setup of 3 pieces of hardware for checking injection timing.

http://mercedes.thatchermathias.com/w123CD2/Program/Engine/617/07_1-108.pdf The 3 pieces of hardware are: 617 589 10 2100 RI- Transmitter 617 589 09 2100 RI- Adapter (for available digital tester) Bosch MOT 001.03 Digital tester I have built my own system which provides the same functions as the above. Just did a bench test and took a short video. On the left is a drill spinning a disc with a screw to simulate the tang behind the injection pump timing plug. Clamped in the vise is the pickup (RI-transmitter) The pickup is plugged into the RI- Adapter (The aluminum box) which outputs to an inductive timing light. The digital tester is just a conventional inductive timing light.  CLICK TO PLAY VIDEO! The portable drill goes up to 1000 RPM. As you can see, tracking is spot on at all speeds! The strobe cutout you see is due to the drill not hard mounted relative to the pickup so the gap moved a bit as I operated the drill. I will be testing this in the car over the next few days and will shoot another video.

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#2

|

||||

|

||||

Nice work! That is awesome  . Should help with IP work. . Should help with IP work.

__________________

"Senior Luna, your sense of humor is still loco... but we love it, anyway." -rickymay ____ "Your sense of humor is still loco...  " -MBeige ____ "Señor Luna, your sense of humor is quite järjetön" -Delibes " -MBeige ____ "Señor Luna, your sense of humor is quite järjetön" -Delibes1982 300SD -- 211k, Texas car, tranny issues ____ 1979 240D 4-speed 234k -- turbo and tuned IP, third world taxi hot rod  2 Samuel 12:13: "David said to Nathan, “I have sinned against the Lord.” And Nathan said to David, “The Lord also has put away your sin; you shall not die." |

|

#3

|

||||

|

||||

|

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#4

|

|||

|

|||

|

Very cool!

|

|

#5

|

||||

|

||||

|

Hmm

Following this experiment.

.

__________________

ASE Master Mechanic https://whunter.carrd.co/ Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 2003 Volvo V70 https://www.boldegoist.com/ |

|

#6

|

|||

|

|||

|

How much did the transmitter and adapter cost? Where did you source them?

|

|

#7

|

||||

|

||||

|

I made them myself.

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#8

|

||||

|

||||

|

That's cool! As a variation on the idea, I'd like to see a test injector rigged up and the timing light pointed at the spray to see the degree difference between the timing signal and the actual injection event.

__________________

-Evan Benz Fleet: 1968 UNIMOG 404.114 1998 E300 2008 E63 Non-Benz Fleet: 1992 Aerostar 1993 MR2 2000 F250 |

|

#9

|

||||

|

||||

|

Impressive! Outstanding results so far.

This is an excellent idea!

__________________

1983 123.133 California - GreaseCar Veg System |

|

#10

|

||||

|

||||

|

Quote:

We are jumping the gun here. Although I am confident what I built will work on the engine, I have not actually installed it on the engine yet.

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#11

|

||||

|

||||

|

Understand that you are still in development. I'm just brainstorming possible applications.

I envision a spare injection hard line, re-bent to run to an injector aimed into a large glass jar. You could connect this to the # one delivery valve and just run the engine at idle on 3/4, 4/5 or 5/6 cylinders. My timing light has an advance adjustment dial so I also imagine that while the engine was running with your trigger mechanism attached, you could adjust the advance dial and shoot the injector spray until you could see the very beginning of the injection event. This exercise would tell you the exact offset between the position of the trigger lug in the pump and the actual injection event and would take into account all of the variables - actual port closure, hard line flex, pop pressure, etc... Then, you could shoot the crank indicator with the freshly calibrated timing light and adjust the pump until the desired indication is reached.

__________________

-Evan Benz Fleet: 1968 UNIMOG 404.114 1998 E300 2008 E63 Non-Benz Fleet: 1992 Aerostar 1993 MR2 2000 F250 |

|

#12

|

||||

|

||||

|

Quote:

Bad news: I suffered a setback today. While installing the sensor into the IP timing plug, I damaged the wiring inside the sensor. It is not salvageable and is now junk since it is potted in epoxy. I have to come up with a better sensor design. What worked so well on the bench is no longer working on the bench. Damn, a lot of work went into that sensor! I have more parts on order which should arrive in a few weeks.

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#13

|

||||

|

||||

|

Quote:

Quote:

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#14

|

||||

|

||||

|

Quote:

Stretch, on the last page of FSM 07.1- 010 operation injection pump with governor, can you translate the labels in the timing diagram? Some of them are in German I think. http://mercedes.thatchermathias.com/w123CD2/Program/Engine/617/07_1-010.pdf

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#15

|

||||

|

||||

|

If I'm understanding your project correctly, you're attempting to emulate a gas engine timing system with a diesel. You've been able to use a VR sensor to trigger a Xenon timing light on the desk. The plan is to use the IP as a trigger wheel and drive the timing light to read the timing on the front pulley. The tang on the IP you're attempting to read should read 15 degrees ADC if the timing is correct. Is that correct?

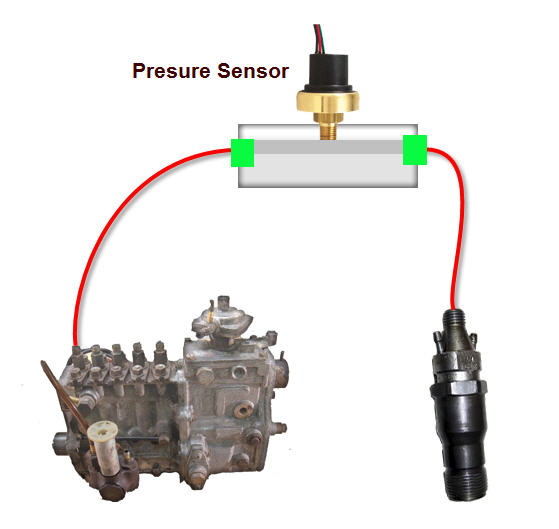

In thinking about the system I wonder if it is possible to use either a piezo pressure sensor or maybe even a piezo knock sensor as a trigger event for the timing light. The commercial systems use some kind of a clamp on the injector line that read the expansion of the injector line as pressure to trigger the timing function... at least that's the way I understand their operation. That would take a pretty sensitive sensor to read the tiny bit of movement of the line wall. I'm wondering if it might be possible to create a more responsive and cheaper system that would use a high pressure piezo sensor or maybe even a knock sensor. What I'm thinking about is two sections of stock injector lines (red) connected at a block of aluminum, brass or steel to the #1 injector outlet of the IP. The green connectors in the below image are modified fittings from the IP. I've made a bunch of these fittings for use in a pop tester - metric injector fittings on one end and 1/4NPT on the other to make fabricating a connector block extremely simple. Reading the signal should be pretty easy, although I think it would be a rising edge rather than a falling edge you'd be looking for. If you can use a knock sensor they're dirt cheap - a pressure sensor, maybe not so much.  I may be completely off base with this idea, but who knows, maybe it would trigger some other options to accomplish the goal. If you're using a VR sensor, you can use almost anything that would fit. RPM and speed sensors off the MB, cam position sensors, wheel speed sensors, and so forth.

__________________

Current Stable

|

|

| Bookmarks |

|

|