|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

Fixed broken Key Head for my 85 300D

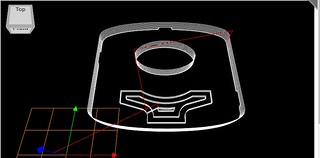

After losing my key I decided it was time to make a key head for my W123 1985 300D. The key had the usual problem of breaking at the plastic. I dropped the key and got locked out of the car for a week till I found it. So I looked around and saw the nice examples here for the billet aluminum key head and the wood versions and the recycled emblem versions. I got inspired and cut my own out of two sheets of acrylic sheet on my CNC router. Here is the project.

Busted key head:   Some CAD/CAM work:   Two identical halves completed.  I made them look as close as I could to the original. My mill cannot do 3D so I just did two simple flat plates with a pocket for the key.  Ready for Glue. I used Gorilla Glue and had good results. It suffered from the glue foaming ooze that Gorilla Glue does. Probably good to clean it off after clamping before the glue gets really hard. Next time I'll mask off the key and the head to keep the surface nice.    Clamped in a cheap pinch clamp:  Clamped it in a pinch clamp overnight. Here is the result. The glue oozed out and foamed up like it does. I'd have cleaned it more had I known how stubborn the glue is when it dries. It lost the smooth finish on the plastic.  Thickness is about right.  I got tired of the glue splotched finish and I grained it with some 400 wet dry sand paper. Looks very nice. I figure it'll get beat up in my pocket. And there it is. Now time to get back to making the car run better. The car is stored at my parents' place and I haven't been able to get to it for awhile. I got impatient and decided to work on this key in the meantime. It came out pretty nice.

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles 97 C280 147k miles Last edited by ykobayashi; 08-28-2018 at 11:57 PM. |

|

#2

|

|||

|

|||

|

Good work on the key head.

I've had good luck using the J-B Water weld or the POR15 epoxy putty to make new key heads. Yeah, the Gorilla glue can make a mess. I won't use it unless there is no alternative. It comes in handy for a quick foam adhesive/filler. Mix it up with some water and apply quickly.

__________________

“Whatever story you're telling, it will be more interesting if, at the end you add, "and then everything burst into flames.” ― Brian P. Cleary, You Oughta Know By Now |

|

#3

|

||||

|

||||

|

Now, go get a dupe made with an all metal key.

__________________

"I applaud your elaborate system of denial" |

|

#4

|

|||

|

|||

|

THAT is the hard part! Finding a real locksmith who has the steel blanks can be tough. Forget about the big box stores or the local hardware guys, they don't carry them.

__________________

“Whatever story you're telling, it will be more interesting if, at the end you add, "and then everything burst into flames.” ― Brian P. Cleary, You Oughta Know By Now |

|

#5

|

||||

|

||||

|

I bought a Myele Ignition Lock Tumbler and it came with a similar plastic key head. I took a knife and split the plastic key head and coated the T end with JB Weld epoxy put the plastic Key head back on and clamped together.

I also bought a set of used locks on eBay and it came with the below Key; see the pic. I have been using Brass Keys since Sep 2007. When my Ignition Lock Tumbler failed The flange/hear of the tumbler separated from the main body of the tumbler. Which had nothing to do with me using Brass keys. Anyone remember that guy 3-4 years ago that sold similar aluminum key head?

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#6

|

||||

|

||||

|

Yeah I’d love to find some steel blanks like the OEM. I’ve used the plated brass and they just turn to dust after a few years. I guess it isn’t bad if they’re cheap but the dust ends up in the lock core.

The other option was to go to MB and get a key made by VIN. I actually live a few blocks from Mercedes Classic Center. But my new frankencar 300d seems to have three different keys. Yep...one for the ignition, one for the drivers door which is missing and one for the trunk and passenger door which is the steel key I rebuilt. My hope is I’ll get the car back to my garage and get all the cylinders on the bench. I think I can pin them alike. (I have a “degree” from the Foley Belsaw Institute in locksmithing  ). Then I can use the single steel key. ). Then I can use the single steel key. The P.O. did a number with the locks. He only gave me two keys and shrugged his shoulders. I promptly lost the key as it fell out of the black head. It took me awhile to find it. It was in the floor of the trunk that had spontaneously locked itself. I still don’t get it, but somehow the trunk lock can go from the unlocked state to the locked state on this car without turning the key...that is something is wonky on the mechanism. I unlock it and put it in the unlock mode and I can open and close it a few times, then on the tenth time it goes “click” inside as I press the button and it locks. I did that with the key tip inside. Luckily the car was open and I was able to fish the key out through the first aid kit. Ahhh, a w123 not a w126.  I saw the links of the aluminum key head guy Conrad. I was inspired by his work. His design was too elaborate for my skills. It takes a couple of setups for the two sided machining and tapped holes. I don’t think my plastic would hold up well with those little screws and the acrylic isn’t as stiff as aluminum.

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles 97 C280 147k miles |

|

#7

|

||||

|

||||

|

Very nice work there, hats off .

Older key shops often have a few all steel rubber head key blanks lying 'round in the misc. box, they have to be extra helpful or really bored to bother looking though . FWIW, 1500 grit wet/dry abrasive will make that key head look even spiffier .

__________________

-Nate 1982 240D 408,XXX miles Ignorance is the mother of suspicion and fear is the father I did then what I knew how to do ~ now that I know better I do better |

|

#8

|

||||

|

||||

|

Ya know, everyone refers to the silver keys as “steel” and I just assumed they were steel. I started thinking they must wear out key machines faster than the brass blanks.

I got a fridge magnet and started picking up my keys. My real MB keys on my SD and the repaired key head unit are indeed steel. Wow. No wonder they don’t wear away. They must have some really hard chrome plating on them too. I’m really regretting tossing my extra 240d keys. Actually the car for that matter as it had great matching locks with steel keys. But at the time I didn’t think I’d own another W123. Oh well. Onward. Well if I do search for steel keys I know how to test them now.

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles 97 C280 147k miles |

|

#9

|

||||

|

||||

|

Quote:

I use that Gorilla Glue for various things but for this particular application I believe epoxy is a better choice.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#10

|

||||

|

||||

|

Anyone remember that guy 3-4 years ago that sold similar aluminum key head?

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#11

|

|||

|

|||

|

Konradwax is the fellow who made the billet key heads. Very good quality. He had some problems with production and stopped selling the key heads. I was lucky and bought 3 of the key heads for my W123 cars.

|

|

#12

|

||||

|

||||

|

That makes a ton of sense. I made about four prototypes. I learned a lot about my CNC machine (I got it twenty years ago and still haven’t mastered its quirks) in the process of making parts.

I actually made 15 or so final key heads. There were some tolerancing issues with the thickness of the key that dogged me. Too deep a pocket and the key rattled, too shallow and the halves don’t close. Then there were CAM issues like how my machine slows down to a snails pace when interpolating an ellipse from circular arcs. I got greedy and tried to make a bunch using a step and repeated design but found out my table isn’t flat enough over a panelized array. Konrad’s design used a lot of straight lines which was smart. But his two halves were different and machined on both sides. A lot of work. My production time was 14 minutes long per half but I really wanted to replicate the profile of the OE key. After I produced a pile of reject parts I realized where Konrad probably was when he threw in the towel. Even at $30 a pop (I recall he asked that much) it was a difficult part to make. Then throw in making from metal and needing anodizing. Good to hear you got a few while it lasted. I was toying with doing metal...aluminum or brass but I figured I’d keep it simple. Like anything “real” it is always harder than it looks. I’m gonna go get my car Sunday. I’m looking forward to making all the cylinders work with the steel key.

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles 97 C280 147k miles |

|

#13

|

||||

|

||||

|

early attempts

First tries

First ugly prototype. Proof of concept.  Learning by messing up. The story of my life. It's easy to make one of something. It's a whole other thing making lots of them exactly the same.

__________________

79 300TD “Old Smokey” AKA “The Mistake” (SOLD) 82 240D stick shift 335k miles (SOLD) 82 300SD 300k miles 85 300D Turbodiesel 170k miles 97 C280 147k miles |

|

#14

|

||||

|

||||

|

Quote:

The other issue is one I experienced myself when I made some special tools for Mercedes is that it becomes too time consuming to deal with a customer here and there. You would make more money simply taking on a minimum wage job or doing overtime. Anyway I believe Konradwax said it was also an issue of dealing with his normal job and then having time to do the other. If someone is going to do this small production stuff I think it would be better to make 100 and then sell on eBay where you stand some chance of getting a bunch of orders at one time and can dump them off at the post office at one time. More efficient.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#15

|

||||

|

||||

|

Quote:

I have not sold many, but have given away several to friends, and with some cars I sold. I am fortunate, in that I don't have a time consuming regular job. I can devote the time it takes to produce these items. I don't (nor can I) rely on the money generated from my efforts. It is "feast or famine" with this sort of thing. It is more like a hobby for me. Many of these items were born out of necessity (much like the key head), and this community benefits from the creation of all these niche items. One day I am sure someone will have these key heads made out of aluminum, and in China (hint-hint)......Rich

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

| Bookmarks |

|

|