|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

Expiremental OM617 build

this is a cross post from STD for anyone interested in a high power OM617 and what goes into building one Hello i don't post a great deal here. however i have been working slowly on a project i have had in mind for a bit. i have a 85 300D w123 that i have been tinkering with for about a year now. my goal is around 300 HP with some reliability. i am aware that the easy way is to go with an OM606 however that has been done before. very few people have taken the 617 to its limit it seems and i enjoy a good challenge. i also enjoy designing my own systems and parts. So far i have maxed out the stock pump and re-timed the pump to 28* along with reamed and chamfered pre-chambers and increased the boost to ~14 pisg. i then got a new head and aggressively ported it till the port walls were around .150" as verified by ultrasound. the new head is waiting to go on till i can re-cut the valves and seats also need a tiny bit of port geometry smoothing still. all this is along with a HE221W i got and a W115 manifold thats on the way. also trying to find a shop that can calibrate AAZ two stage injectors with DN0SD315's. the long term plan is to get a compound turbo setup running a HE211W or HE200WG as the HP and either a HX35 or 40 as the LP. i am running a rigged water methanol system from the washer bottle right now and i am intending to replace that with a true high pressure injection system. also looking into getting a set of rods made for the engine but thats gonna cost a great deal so its far down the list. also investigating thermal barrier coating companies about the pistons and the pre-chambers. theres a great deal of other ideas too that i intent to explore. the max rpm capability of the engine is a question i am wondering about. considered buying a junkyard tired engine and pulling the high idle governor from the pump than running it in 500 rpm increases followed by compression tests to find the rapid degradation point or just see when the rods go for a walk. pictures to come as i can host them.

__________________

1985 300D om617: 8mm M pump 175cc 5200rpm, holset he221w @ 30psi, large A2W ic, compounds on the way. KD9AFT A&P |

|

#2

|

|||

|

|||

|

i got the turbine housing discharge flange made by a local shop for me. its got a minimal amount of material blocking the exhaust flow and a 3" v-band outlet. kind of ridiculous but every bit less of restriction post turbo helps.

i also ceramic coated the exhaust manifold. mind you its not a high quality coating but everything helps, and i dont intend on keeping the EGR manifold for long. looking into using a W115 N/A exhaust manifold to feed a twin scroll housing on the HE221W (TD04HL housings fit the hot side of the 221 and there is a 8.5CM twin entry housing for them.)  it kind of amazes me that the HE221W can flow as much air as it can upwards of 36LBS/minute  in other news i am in the process of getting a quote from Pauter for a custom set of connecting rods. not going to need them any time soon but i just wanted to know how much it would be. they make a rod that is almost exactly the same as the 617 but the small end is ~1mm too small. Its for another Mercedes but i cant remember what off the top of my head right now. ill keep posting as more progress and pictures come.

__________________

1985 300D om617: 8mm M pump 175cc 5200rpm, holset he221w @ 30psi, large A2W ic, compounds on the way. KD9AFT A&P |

|

#3

|

|||

|

|||

|

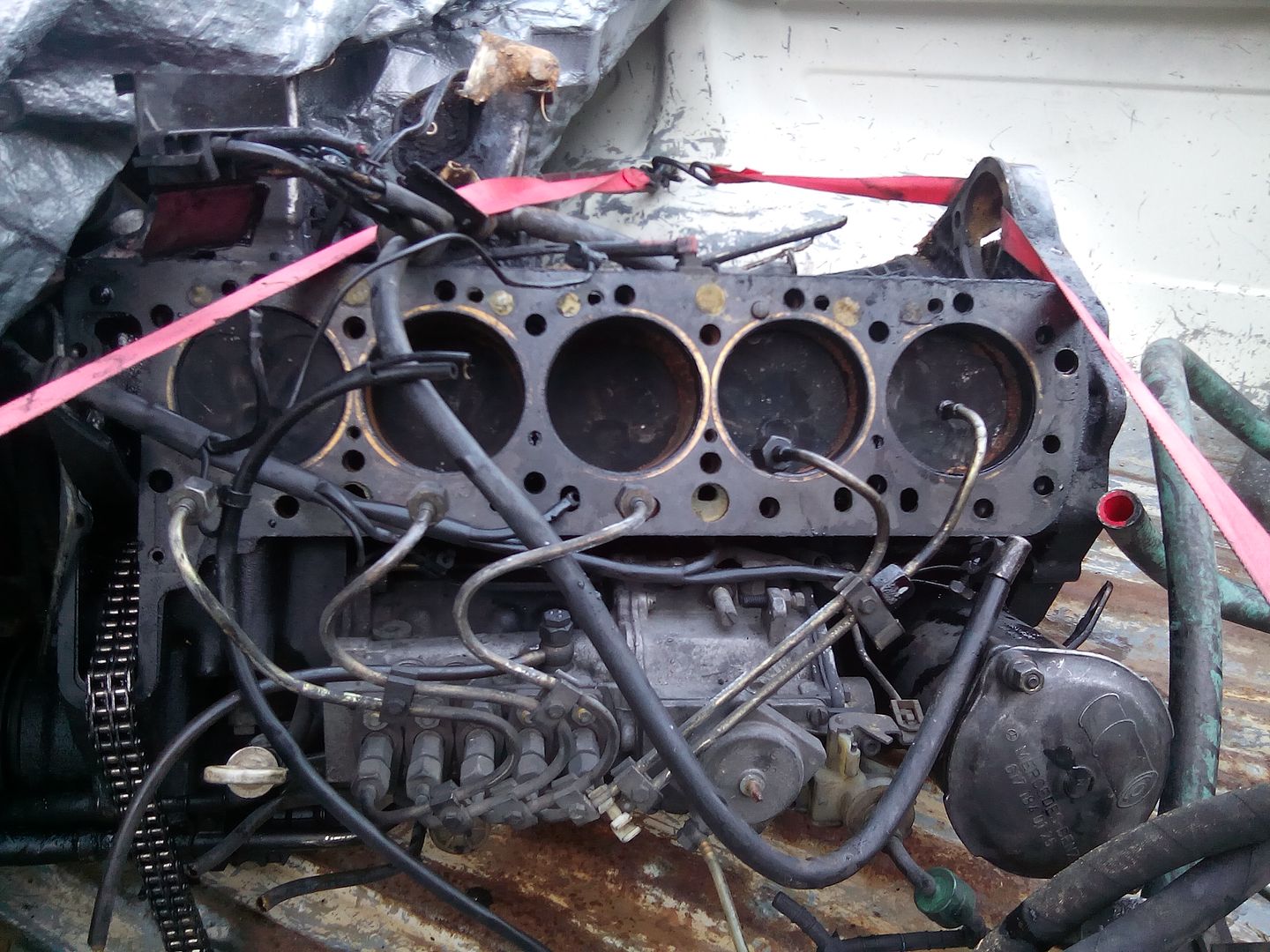

spent most of today wrestling with the engine. i managed to get the seized nuts off the manifolds to pull the stock turbo after soaking them in ATF mixed with MEK. (this is the best penetrant oil i have ever used it even beats the Boeing stuff i used to have that was banned in most states for toxicity) also i just love the nice residue the EGR leaves behind in everything it touches.

i also found the source of the slight rattle and drone at some speeds. guess i have no excuse now not to have a 3" DP made. i might even "forget" to re-install the exhaust past the DP for a bit just to see how it sounds with the HE221W and a strait pipe.  the next step is to mount the new turbo with the w115 manifold. i would like to get the new head on however it still needs some work before its ready. i did get new valve guides and the porting but it needs valve sealing work and a little smoothing.  i think i removed around half a kilo with all the porting. the port walls are quite thick somewhere around 10-13mm.  i got the w115 manifold in today. also i needed to replace my engine mounts so i got a new set an cast them full of rubber (PR seal if anyone is familiar with it. its horrible stuff its smell awful and gets everywhere but once cured its amazingly indestructible)

__________________

1985 300D om617: 8mm M pump 175cc 5200rpm, holset he221w @ 30psi, large A2W ic, compounds on the way. KD9AFT A&P |

|

#4

|

|||

|

|||

|

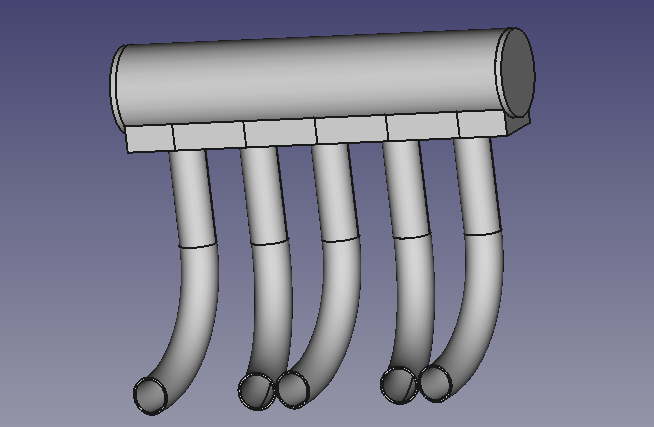

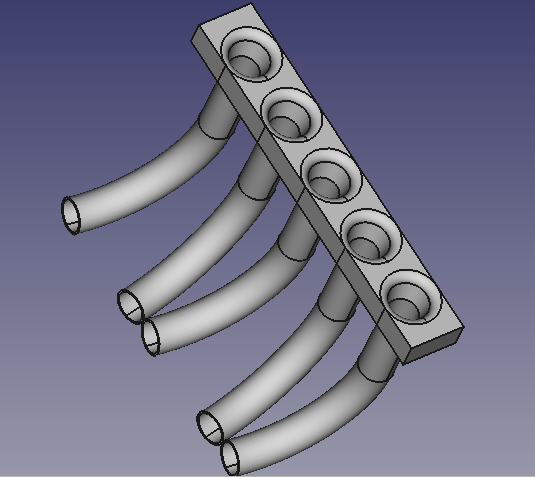

i have been experimenting lately with designing a resonant tuned intake manifold styled after the w115 manifold but with better flow characteristics. the first step was to establish the resonant frequency of the valve acoustics at desired RPM. i chose to model the intake for 2800-3100 and 4000-4500 as two of the primary tuned harmonics. this should establish better airflow at cruse rpm (~3000 for me) and maximum HP which stock is 4350 but i figure i should be able to push that up to around 4500 with some governor tweaks. modeling the intake is two method approach as i am trying to figure out the Helmholtz resonance of the plenum as one volume and the runner resonance as another. so far i have established an ideal runner length of 18.91" (480.3mm) and a cross sectional area of 1.39"^2 (9.02cm^2). this is all rough estimation, however even if it is a bit off the 3rd and 4th order harmonics i am targeting should fall somewhere in the usable power band. based on these dimensions i started designing a manifold with the main goal being ease of construction and optimal air flow. i have access to a CNC mill so i intend to use it for one part of the manifold however most of it is basic aluminum sheet and tube stock.

the core of the manifold is a bar of 6061-T6 16" X 2.5" X 1.25" with a series of bell-mouths into the runners. this is the only part that needs special construction and you could probably get around that with ebay velocity stacks, some plate aluminum, and a tig welder.  i wont be building this manifold for a bit yet as i just got the w115 manifold on. however sometime in the future ill get around to it. once i finish modeling the airflow dynamics and have a good set of .DXF files i will post them somewhere for anyone who wants them. in other news i am waiting for the last parts to get the down-pipe together and some charge piping before i can get the 300D back on the road. i briefly ran it with nothing from the turbo back and its ridiculous. you can't make out the engine tone over the turbo whine above 3K rpm free revving it. i re-clocked it some after this picture to better situate the outlet and the oil drain.  here's how i adapted the drain line to the block not elegant but it works.

__________________

1985 300D om617: 8mm M pump 175cc 5200rpm, holset he221w @ 30psi, large A2W ic, compounds on the way. KD9AFT A&P |

|

#5

|

|||

|

|||

|

i got the new 3" down pipe on today and finished plumbing in everything. then took the car for a test drive. sounds amazing however i noticed a strange hissing/scratching noise at idle when i got back. popped the hood didn't see anything revved the engine a little. promptly the alternator exploded and shorted the battery managed to get it unhooked fast enough to prevent serious damage but now i need to install a new alternator and redo the wiring harness. yay. i have a new AL129X and 1/0 cable coming soon so ill just redo the entire layout might try to get the battery in the trunk.

__________________

1985 300D om617: 8mm M pump 175cc 5200rpm, holset he221w @ 30psi, large A2W ic, compounds on the way. KD9AFT A&P |

|

#6

|

|||

|

|||

|

the car has been doing well with the new turbo. it maxes out at 17 psi right now however it doesn't like to make more than 10 psi below 3000 RPM. i would like to drop that to 15 but as it is i think its leaking drive pressure from the WG due to reducing the WG spring pressure too much. i might try feeding it vacuum with a manual boost controller to feed pressure once the set point is reached. ill have to see if that helps. in other news i picked up a new short block to go with the head i have been doing a lot of work to.

the head has been ported as far as i am comfortable with for now. the short side radius on the stock ports is atrocious, also the intake runners decline into the valve while the exhaust is almost a direct 90 degree turn. i contemplated reshaping the chambers and valve reliefs to help reduce valve shrouding but without a flow bench and a few spare heads to play with thats a dangerous move.  i talked to Geoff at Colt cams about a bigger cam to go with the better head flow. He said they have a few profiles for the OM617 that are good for a little more flow without hurting the low down power, so ill be ordering one as soon as budget allows. he also was interested in creating something more extreme when i mentioned the ported head and the other work i have been doing. so maybe once this car is no longer a daily ill look into going a bit farther. i am currently tearing the short block down to see what needs replacing while also getting some ideas for other things to tinker with. something that interested me was the timing advance mechanism, according to the FSM the early models prior to 1980 have 8 degrees of advance while the later have 7.5. i am considering grinding the stops to allow another 1-2 degrees of advance. this should hopefully help increase the usable power band a bit as even if you tinker with the high idle governor it still falls on its face above 5K. Sorry for the rambling i genuinely enjoy testing ideas and seeing what sticks. if anyone has had any similar ideas feel free to chip in im game.

__________________

1985 300D om617: 8mm M pump 175cc 5200rpm, holset he221w @ 30psi, large A2W ic, compounds on the way. KD9AFT A&P |

|

#7

|

||||

|

||||

|

Quote:

The large fitting gets JBWeld-ed into the upper oil pan and connected to a standard AN-10 turbo drain fitting with stainless braided hose. The smaller fittings were made for my catch can drain hose which uses -6 hose. Since these are essentially zero pressure applications, my tolerances are definitely good enough - though obviously not mil-spec.

__________________

Current Stable

|

|

#8

|

|||

|

|||

|

that early adapter worked for a while but i have since welded an AN10 bund into the side of the upper oil pan. as for the blow-by port i did some testing and found the stock port is too restrictive if you plan on running more than stock boost due to the ring end gaps being so loose on these engines. as such i drilled two holes in the upper plenum behind the oil separation baffle in the valve cover and ran two AN10 lines to a oil vapor separator which discharges into the bottom of the valve cover by the timing chain hump. the blow-by is the sent to an extractor venturi in my down pipe. something interesting to note is that a lot of the generic OM617 oil leaks stopped once i had done this it seems the stock case pressure management system is insufficient to prevent some build up and thus pushes some oil out various seals.

__________________

1985 300D om617: 8mm M pump 175cc 5200rpm, holset he221w @ 30psi, large A2W ic, compounds on the way. KD9AFT A&P |

|

#9

|

|||

|

|||

|

Hey R-3350, thanks for sharing. Nice project! I am interested to see how the engine runs when you get your IP back. I have a OM617 I am trying to put into a W110, but the accessories make the engine too long.

|

|

#10

|

|||

|

|||

|

Interesting! You're WAY deeper into this than I am with my race engine but I have to be VERY budget conscious (read, cheap) on mine given limited funds in retirement. It'll be cool to see how all of this works out.

Where in NC are you? I noticed the plate in the one rear shot. I'm in Wilmington and it would be fun to get together and swap lies. You might be interested in my side-mount engine stand adaptor. It works great and keeps from hanging the engine off that aluminum plate (probably OK but it worried me). If you get over this way I'll show you the mount adaptor - my spare engine is hanging on it as we speak. Dan |

|

#11

|

|||

|

|||

|

im in boone, if i visit the coast any time soon ill have to see if i can stop by we can trade stories. as for the engine block as it is it weighs nothing i can pick it up so im not too worried. i used that stand to rebuild a 6.9 idi engine a while ago for my truck all told that beast is 1400lbs so i doubt it will have an issue with the 617 plus im getting rid of the stock end plate to mount a new trans once the new pump comes in.

__________________

1985 300D om617: 8mm M pump 175cc 5200rpm, holset he221w @ 30psi, large A2W ic, compounds on the way. KD9AFT A&P |

|

#12

|

|||

|

|||

|

Please do! I'll be gone to FL for July and August for cancer treatment but other than that I'm around.

Dan |

|

#13

|

||||

|

||||

|

I think winmutt must approve you on STD, and he doesn't come around much anymore, but eventually you'll get in.

|

|

#14

|

||||

|

||||

|

I'm glad to see someone else porting their manifolds, those stock castings are mediocre at best.

I'd really like to hear how the cam turns out, that's the one bit I haven't looking into yet. Do you think it will harm the street manners?

__________________

$60 OM617 Blank Exhaust Flanges $110 OM606 Blank Exhaust Flanges No merc at the moment |

|

#15

|

|||

|

|||

|

Quote:

Um - what are street manners?  (Not part of my agenda.......) Dan |

|

| Bookmarks |

|

|