|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

Quote:

I had not checked the C-clip for hardness. However, the replacement I bought is a genuine GM one and the one on the opposite side has a shiny wear areas but is not grooved at all. All of the Bearings I bought are USA Made and the same Timken or Torrington Bearings that came off. I bought the on eBay. Besides the Cost one of the eBay advantages when buying a bearing is you can often see if they are US Made or ask the Seller. I wanted the exact same Bearings as I am hoping not to have to fuss with the Differential Carrier Shimming too much. I sure did not want one of those Bearing Kits with unknown bearings. I have reached an Impasse concerning the replacement Spider Gears. I have tried 2 Sets and neither fit correctly. The Seller of the Last set refunded all the Money and left Me with a free set that does not fit. Today I went to what was supposed to be a local Speed Shop that sold Yukon Gear sets and the address turned out to be an Apartment House with no other businesses in it??? Likely that Person is only an internet seller. I wanted to deal with someone over the Counter. Since I need to get the Van running and moved I am going to install the New Bearings, shim it if needed and I am going to stuff the old Gear back in and deal with the issue at a later date. That is not hard to do as it is easy to change the Gears on the Vehicle. Anyway that will buy Me time to get some Gears. The only other issue I found is that the Pinion Gear did not have even the minimum preload on it. I am going to fix that tomorrow. Bought a used inch pound Torque Wrench as the inch pound to do the job that came Yesterday.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#2

|

||||

|

||||

|

I forgot to mention. I also had what firs appeared to be a Pinion Seal leak.

The Seal actually rids on the shaft of the U-joint Yoke and the Seal wear area was not deep. However, the U-joint Yoke is bored all the way through. after the Nut is removed and a Washer is removed you can see the splines on the Pinion Shaft and the Yoke Splines. So apparently since then Pinion Gear did not have even the minimum preload on it the Washer was not pushed up against the spline area so there was no way it was sealing in that area. Once the Oil seeped past the splines and washer it was flung to the side and is on the underside of the Car. There was some sort of sealant on the Splines but it was all dried and crumbly and mostly gone.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#3

|

||||

|

||||

|

Well today the job beat Me.

I got the Pinion Gear with new Compression/Spacer Sleeve assemble. I started tightening the Shaft Nut to compress the Spacer Sleeve and found everything came to a halt. No matter how much strength I tried to exert I could not take up any play. It was to the extent that I though I had somehow forgotten to the Spacer Sleeve or it had fallen off. I pulled the Pinion Gear out and the Sleeve was there. The next though was I had forgotten some other Washer or Spacer. I looked in the Manual and I had all the parts that are supposed to be there. So I tried again and found that with the Position that the Van is in I am simply not going to be able to get enough force to turn the Nut. And, there is no room for a longer Cheater Bar or My 3/4" Drive with its longer Handle and it comes with another Handle to act as a cheater Bar. But, there would be no room to move the Handle much. Another thing I noticed is that the original Sleeve/Spacer is pooked out more than the new one. Even considering that the used Sleeve/Spacer is squashed about 1/16" shorter tan the New One it had a much wider pooked out area. Meaning that I think that the New Spacer/Sleeve if much closer to a straight Tube than the Original Spacer/Sleeve was when it was New. Tomorrow I will assemble the Pinion Gear with the Old Sleeve/Spacer and see what I get with that. If I am Lucky I will be able to compress the Old One a bit more and get the proper Preload. If that does not work out I am going to the Auto Parts Store to see if they have another Sleeve/Spacer. If the Auto Part Store one is pooked out more than the New One I have I am going to buy that one and hope it will be easier to compress. If I cannot compress any of the Sleeve/Spacers the way the Van Sits now (on the Grass) I might have to dig a hole under the Van in order to get the longer Handled 3/4" drive to work. I don't have a Torque Multiplier but if there is enough room for it that might be something that will work.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#4

|

|||

|

|||

|

It takes a lot of force to crush a new crush collar. Be careful as it does not take much rotation to go from zero preload to too tight.

If you have a floor jack, put that under the breaker bar and jack it up. |

|

#5

|

|||

|

|||

|

On the side gears, did you see if they fit the axle splines?

Early rear ends were 7.5 with low count of splines, later 7.625 had higher spline count. Perhaps the rear was changed at some point. |

|

#6

|

||||

|

||||

|

Quote:

The First Kit had on the small Spider Gears a 10 thousands clearance on the Shaft and that was greater the already worn gears. So I sent that Back. The Next kit I got fit so tight that you cannot rotate the Gears in the Carrier by hand. They refunded the Money and did not ask for the Kit back. Neither of those problems had to do with the Axle Splines.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#7

|

||||

|

||||

|

Quote:

Even taking into account that the old Tube is compressed it appears that the Old Tube had a larger more well formed pooked/bulged area then the New Aftermarket Tube. The New Tube barely has a pooked/bulged area and is almost a straight tube. I also think the New tube has a slightly thicker wall thickness. I think the shape of the older Tube made it easier to compress than the new Tube. I am going to try the Old Tube Tomorrow if that works I will use that. If it does not work I will go to the Auto Parts store and see if they have another Tube that has a easier to crush shape.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#8

|

||||

|

||||

|

Whist I have no experience of Astro diff crush collars - on the W114/5/6 W123 W126 trailing arm wheel bearings that bugger is an almighty git to get going...

...there was so much grunting in my garden during that job the neighbour poked her head over the hedge to try and get an eye full...

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#9

|

||||

|

||||

|

OK the Pinion Gear Preload is done using the old Sleeve.

The used bearing preload is 8-12 Inch Pounds and the new Bearing Preload is 24-32 Inch Pounds. Since I changed the Small Pinion Bearing on the U-joint Yoke end and reused the Pinion Gear End Bearing and Race I compromised and set it at 20+ Inch Pounds. It is a Beam type Torque wrench so I can't get fine accuracy on it. In order to make it harder to over crush the Sleeve I used a click type Torque Wrench to tighten the Shaft Nut I bumped the torque up 15 or 10 Foot Pounds at a time. It took 135 Foot Pounds to get the preload.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#10

|

|||

|

|||

|

The crush collar keeps pinion bearings seperated and keeps tension on the pinion nut. The new one could use a bit more of a bump. Was it OE GM?

|

|

#11

|

||||

|

||||

|

Quote:

I was able to reuse the Old Crush Collar. When the Pinion Shaft Nut was tightened down as much as I could with a normal sized Ratchet Wrench I was getting a preload of 10 inch pounds. After tightening the Nut more in stages (ended up with 135 Foot Pounds on the Nut) I had 20+ inch pounds of preload. I that is where I stopped.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#12

|

||||

|

||||

|

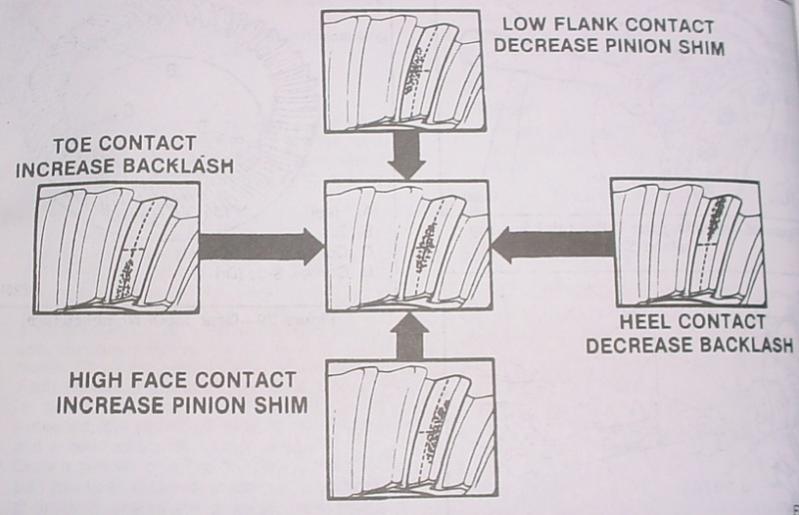

The Differential Carrier bearing preload is OK.

The Gear Back Lash spec is only for New Gears and is 0.13-0.23mm. My actual used Gears Back Lash is 0.20mm so that is within the New Gear Spec; so I am leaving that alone. For the Gear Tooth Contact Area I did not have any Lubriplate so I just used a lumpy coat of Wheel Bearig Grease. From the Pics I believe I am getting very good Gear Contact both coming and going on the Gear Teeth.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#13

|

||||

|

||||

That's a very handy bit of information Where did you find it?

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#14

|

||||

|

||||

|

I have the official Chevrolet Manual for the Van an that chart is in the Manual.

However, I have seen similar charts in other Manuals. The only thing that is different is in the others there is a separate Pic for each wear pattern and you need to change to correct it is not with the pics; you need to find it in the Text of the Manual. I have not searched the Internet but I guess that info could be there also.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#15

|

||||

|

||||

|

Thanks I'll hunt about for it

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

| Bookmarks |

|

|