|

|

|

|

|

|

|

|

|

|

|

#1

|

|||

|

|||

|

Question about changing a vac pump

As soon as I get my new vac pump, I want to get it on my car. After looking at the old one, it looks as if I may have trouble getting one of the bolts out. There is some kind of shock/spring that is preventing me from getting full access to this bolt (it's the one on the far passenger side of the pump). I couldn't figure out how that shock comes out, does anyone have experience with this?

__________________

87 300D - Running on Veggie oil; 260,000 plus miles; Original #14 head

|

|

#2

|

||||

|

||||

|

You should remove the belt for better access. Also detatch the top mount of the tensioner damper (shock absorber). This will allow you to pivot the tensioner arm and puller out of the way of the pump. Good time to check for smooth click free pivoting of the tensioner arm and smooth quiet spinning of the tensioner pulley.

I read that if the driving cam is pitted or has wear marks, it should be replaced. I don't recall if the driving cam is part of the timer and if so does the timer have to come off to replace the driving cam. It's best to loosen the pump bolts a little at a time since the pump lever is pushing against the driving cam, pushing the pump forward. There might be a sweet spot where the lever is against a low in the driving cam but I don't know how that relates to a crank pulley position. Sixto 93 300SD |

|

#3

|

||||

|

||||

|

To do this job, yank the fan & clutch, remove the serpentine belt & shock, and pull the upper radiator hose. That will give easy access. Leaving that stuff in place will make the job at least unpleasant, if not impossible. The cam is an integral part of the timer, so if the cam is worn, the timer needs to be replaced (not likely though). Clean the surfaces very well and install the new gasket dry (no RTV needed). Turn the crank as needed so the pump wheel is at the lowest point on the cam when re-installing, and tighten the bolts evenly in a criss-cross pattern. DO NOT overtighten the bolts!

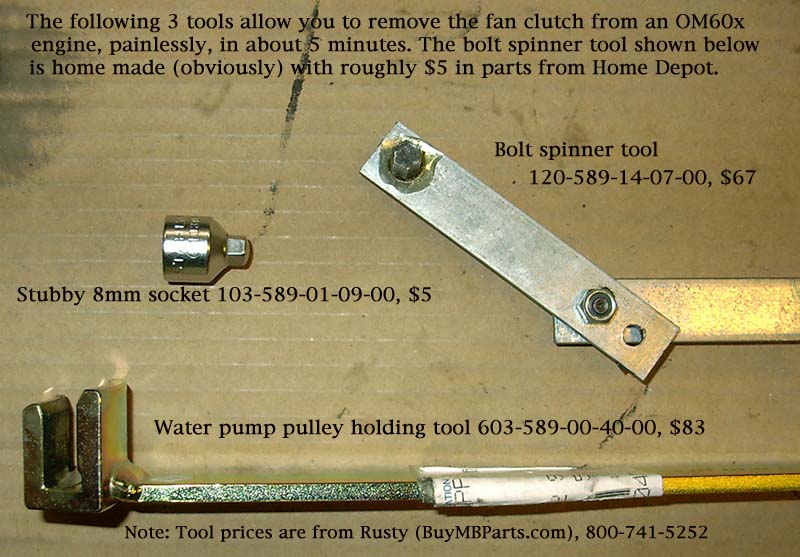

If you don't have the tools to pull the fan clutch quickly, I'd strongly recommend buying and/or fabricating them, as shown in the photos below. These allow removal of the fan & clutch in literally 2 minutes:

__________________

Check out my website photos, documents, and movies! |

|

#4

|

|||

|

|||

|

I've found a way to get the fan off without any expensive tools. I just took an allen wrench and cut about 3/4 of an inch off the end to allow enough clearance between the fan and radiator. Then I took my channel locks to hold the pully in place and put a breaker bar on the allen wrench, got the bolt loose, then took some tie straps and tied the allen wrench to one of the fan blades. Then it's a simple matter of rotating the fan till it comes out. Installation works the same way.

__________________

87 300D - Running on Veggie oil; 260,000 plus miles; Original #14 head

|

|

#5

|

|||

|

|||

|

Quote:

|

|

#6

|

|||

|

|||

|

I didn't have a whole lot of pressure on it, there is a certain way to put the channel lock on the pulley, and you don't have to squeeze too hard. I have heard of people using C clamps, and I would imagine if you crank one of those too tight it would deform the pulley.

__________________

87 300D - Running on Veggie oil; 260,000 plus miles; Original #14 head

|

|

| Bookmarks |

|

|