|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

If I posted on weldingweb they would have seizures from overexposure to AWESOME!

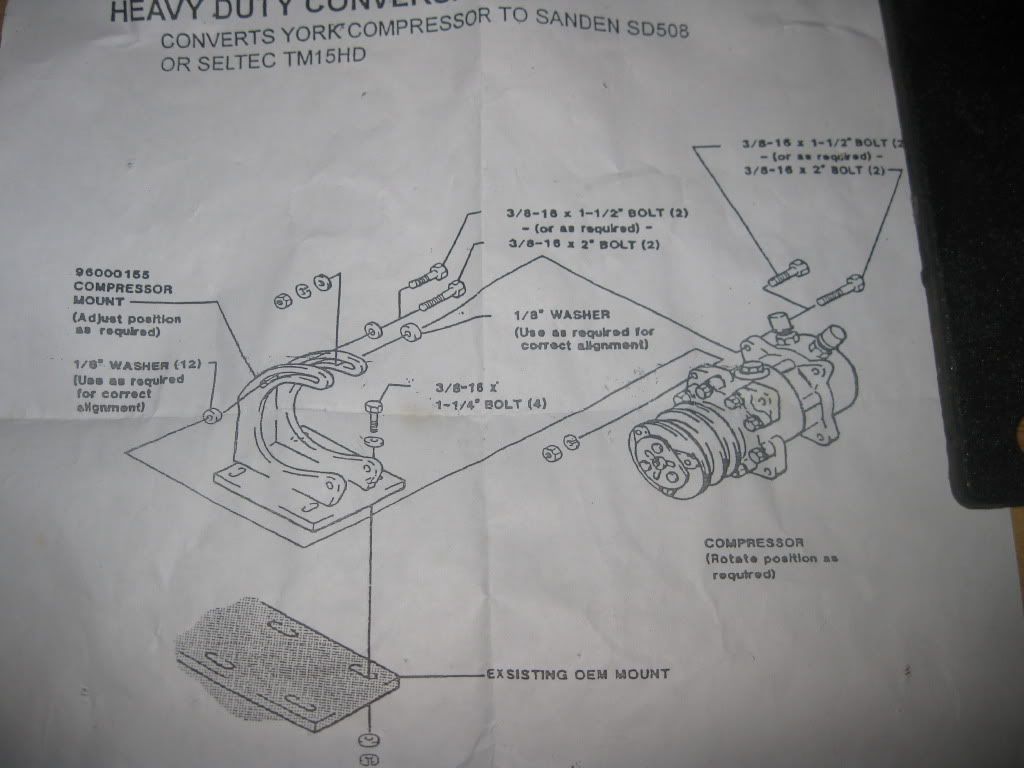

Yea, I almost took it some where to be welded but I was worried about warpage. Believe it or not it did shift from the position of the tack welds  I had to move around to avoid too much distortion and you have to get it HOT to get decent penetration. The job really calls for a bigger machine than mine and better skill than I possess. This is how the bracket is supposed to be used:  I just figured the single bolt would be stronger but I may look at using some welded nuts or threaded rod. A slightly shorter bolt may work as well... Some pics: This is it with the manifold tubes and the power steering pump in place.  I think I would be wasting my time even trying to fit the oil cooler lines  Without power steering pump:  Bench shot:  Those fittings are supposed to be everything I need to rig this stuff up. You can see how much clearance you lose with the 90 deg fittings off the compressor. I rechecked and it looks like the oil cooler lines WILL clear. Thank God...

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD Last edited by 1980sd; 07-06-2011 at 02:06 AM. |

|

#2

|

||||

|

||||

|

Fooled with it a little tonight:

I got an FK head because I hoped the service valves would be accessible but I decided to put 134a manifolds on it as well. Everything clears the oil lines but plain 90 deg manifolds would allow the lines to point either direction with plenty of room. The way it is now the 134a ports prevent them from being positioned the right way. (Hi to the front/lo to the rear.) There is still room to turn them around but it would put the hi port directly under the power steering pump and I don't think I could access that port with a gauge manifold. It's tight in there but not as tight as the pic makes it look. I mainly did it like this so it would be easier to try out both refrigerants if I want too. Anyway... So far so good. I need to rig up an oil cooler line bracket on one of the compressor arms that will allow enough clearance to get to the tensioning bolts. Front view:

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD Last edited by 1980sd; 07-06-2011 at 11:41 PM. |

|

#3

|

||||

|

||||

|

So far so good! I drove 410 miles and checked it and the belt tension is holding. Today I drove about 30 miles with the compressor engaged and all looks fine.

Thanks again for the help Jim! I never would have thought of that!

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD |

|

#4

|

||||

|

||||

|

Anytime Jon.

Did it maintain the under 40dF vent temps at highway speed?

__________________

Jim |

|

#5

|

||||

|

||||

|

Quote:

The belt looks fine but I'm wondering if it got glazed from slipping? The belt looks fine but I'm wondering if it got glazed from slipping?The tension is holding fine though. I'm also going to put the flat washers on the adjustment bolt like you suggested.

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD |

|

#6

|

||||

|

||||

|

Post the gauge pressures at 1500 rpm and idle. I'm wondering if the compressor is cutting out on low pressure while at speed.

How much freon did you put in it?

__________________

Jim |

|

#7

|

||||

|

||||

|

2 lbs of 134a. I have an LED light that is illuminated when power is applied to the clutch. It has never gone off... No cycling, nothing. I have a binary switch (more for safety than any CCOT stuff) that is 10psi and 375psi. I'm relying on the evaporator switch for cycling.

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD |

|

#8

|

|||

|

|||

|

Any thoughts ? Yes, worthless information coming from a halfway test..

Put the fan in front of the radiator like the test calls for and tell us what happens...

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/diesel-discussion/10414-help-i-need-check-stretch.html http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#9

|

||||

|

||||

|

OK. Big fan in front of mein auto. Simulate autobahn speeds...

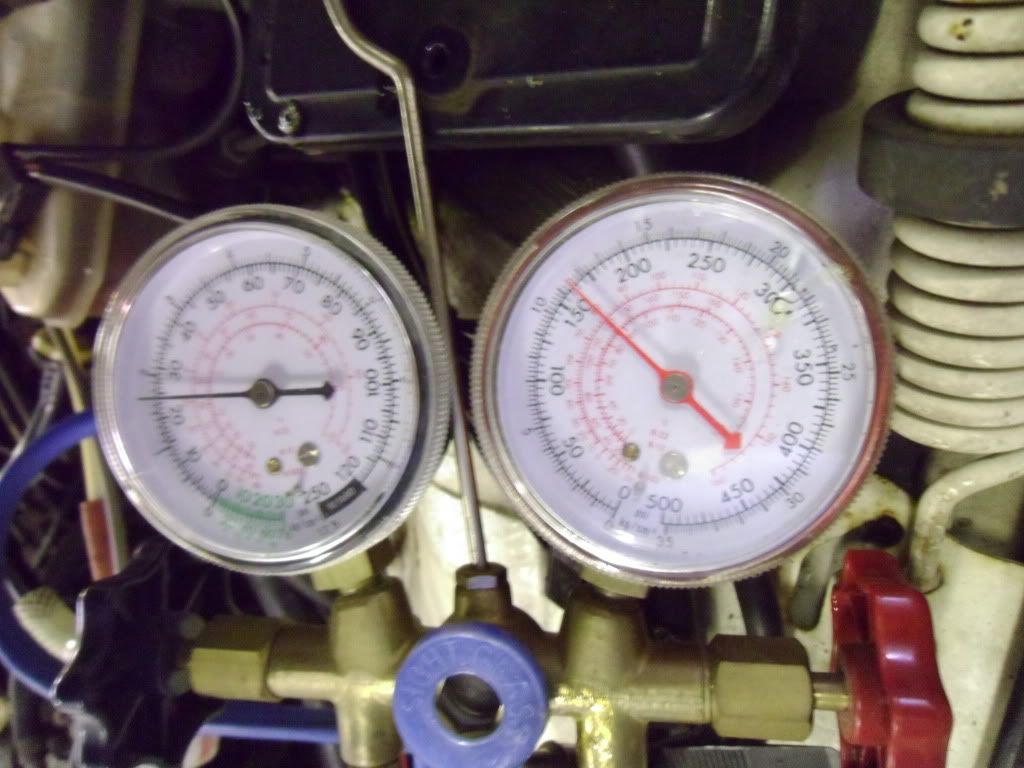

Ambient 72F I got 72 psi when the gauges were hooked up. Compressor ON fan on high, doors open... lo 15 psi high 130 psi. It rose to 17/140 after 5 minutes of running. Temp at center vent 39 F. 1500 RPM: Lo dropped to 10 psi and hi rose to 150 psi. After it returned to idle the pressures stabilized at 15/140. Vent temp was 37 F. The low pressure is getting pretty close to the low pressure shut off but it hasn't cycled that I can tell. Better than being close to trippin' the hi pressure switch!

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD |

|

#10

|

|||

|

|||

|

What is your relative humidity ?

My book specifies that after the 3rd cutout of electromagnetic clutch the air outlet temperature should be approx +3 degrees C, and should not be less than 1 degree C....

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/showthread.php?threadid=10414 http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#11

|

||||

|

||||

|

28%

+/- 3/-1 C of what? The temps when the compressor was running? The temperature of the sun? It was charged with 2 lbs of 134a. I'll look up the pressures when it was first charged but I believe it was about the same. This was at 82 F:   Humidity was 34% that day. It sure sounds like the low pressure switch could be switching the compressor...

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD Last edited by 1980sd; 10-03-2011 at 08:00 PM. |

|

#12

|

||||

|

||||

|

Seeing as how it is a home made design I'd suggest trying some different charges - 1.8#, 1.9#, etc.... until up to say 2.5# and document the performance to see where the most ideal charge is.

Your system holds more volume than the original. You are on the cutting edge with this system Jon  . .

__________________

Jim |

|

#13

|

||||

|

||||

|

I just checked the label from the conversion in 2001

"8 oz PAG" "28 oz R134a" Interesting that I put 8 oz of PAG 100 in mine along with the oil the compressor shipped with. I need a vacuum pump so the plan is to evacuate, deal with a small leak, vacuum it well, change the accumulator and recharge like you said Jim. I suspect that I have more oil than I need because the new compressor has a sump. I figure opening the accumulator up will tell more about oil volume. The belt is holding well  I probably have 1000 miles of running on it and it looks fine! I probably could tighten it slightly more but I'm trying to sneak up on it I probably have 1000 miles of running on it and it looks fine! I probably could tighten it slightly more but I'm trying to sneak up on it  Greg must be fixing his AC

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD |

|

#14

|

||||

|

||||

|

Yea, the belt will stretch a little.

__________________

Jim |

|

#15

|

||||

|

||||

|

Quote:

I just remembered my lo/hi pressure switch is on the receiver so it wouldn't trigger when the lo pressure on the accumulator drops below 10 psi. I just wanted to add that when I had it charged the pressures were 30 psi low and 200 psi hi. The temps were in the 90's then. Looks like I've lost some refrigerant through a leak and monkeying around with the gauges. Would ambient temps cause the pressures to be THAT different? Someone look it up in a book...

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD Last edited by 1980sd; 10-03-2011 at 09:59 PM. |

|

| Bookmarks |

|

|