|

|

|

|

|

|

|

|

|

|

|

#46

|

|||

|

|||

|

What is your relative humidity ?

My book specifies that after the 3rd cutout of electromagnetic clutch the air outlet temperature should be approx +3 degrees C, and should not be less than 1 degree C....

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/diesel-discussion/10414-help-i-need-check-stretch.html http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#47

|

||||

|

||||

|

What is the low pressure cut out set at? Your low pressure sounds low to me. How much r134 did you charge it with?

__________________

Jim |

|

#48

|

||||

|

||||

|

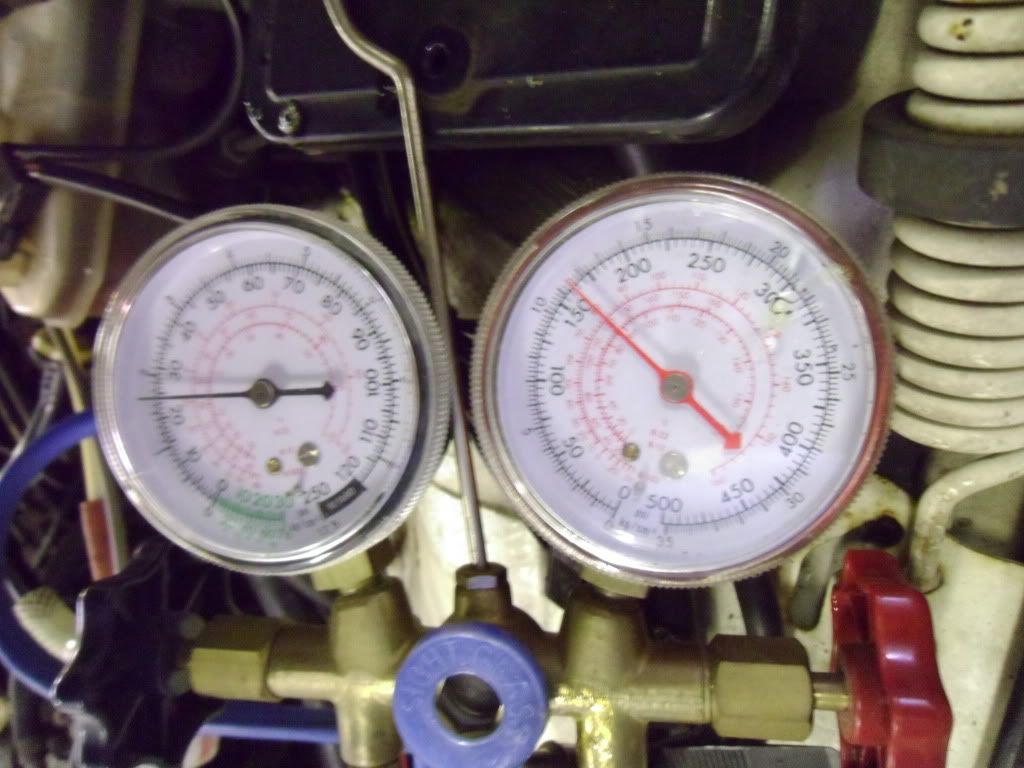

28%

+/- 3/-1 C of what? The temps when the compressor was running? The temperature of the sun? It was charged with 2 lbs of 134a. I'll look up the pressures when it was first charged but I believe it was about the same. This was at 82 F:   Humidity was 34% that day. It sure sounds like the low pressure switch could be switching the compressor...

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD Last edited by 1980sd; 10-03-2011 at 08:00 PM. |

|

#49

|

||||

|

||||

|

Seeing as how it is a home made design I'd suggest trying some different charges - 1.8#, 1.9#, etc.... until up to say 2.5# and document the performance to see where the most ideal charge is.

Your system holds more volume than the original. You are on the cutting edge with this system Jon  . .

__________________

Jim |

|

#50

|

||||

|

||||

|

I just checked the label from the conversion in 2001

"8 oz PAG" "28 oz R134a" Interesting that I put 8 oz of PAG 100 in mine along with the oil the compressor shipped with. I need a vacuum pump so the plan is to evacuate, deal with a small leak, vacuum it well, change the accumulator and recharge like you said Jim. I suspect that I have more oil than I need because the new compressor has a sump. I figure opening the accumulator up will tell more about oil volume. The belt is holding well  I probably have 1000 miles of running on it and it looks fine! I probably could tighten it slightly more but I'm trying to sneak up on it I probably have 1000 miles of running on it and it looks fine! I probably could tighten it slightly more but I'm trying to sneak up on it  Greg must be fixing his AC

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD |

|

#51

|

||||

|

||||

|

Yea, the belt will stretch a little.

__________________

Jim |

|

#52

|

|||

|

|||

|

If I say 75 degrees F.... that is 75 degrees F....

not relative to anything except on the F scale to freezing and boiling of water on a standard barometric day.. If I say between 1 degree C and 3 degrees C... that is just that... and that also is in relation to the boiling and freezing point of water on a standard barometric day....

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/showthread.php?threadid=10414 http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#53

|

||||

|

||||

|

Quote:

I just remembered my lo/hi pressure switch is on the receiver so it wouldn't trigger when the lo pressure on the accumulator drops below 10 psi. I just wanted to add that when I had it charged the pressures were 30 psi low and 200 psi hi. The temps were in the 90's then. Looks like I've lost some refrigerant through a leak and monkeying around with the gauges. Would ambient temps cause the pressures to be THAT different? Someone look it up in a book...

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD Last edited by 1980sd; 10-03-2011 at 09:59 PM. |

|

#54

|

|||

|

|||

|

Your car thinks you are crazy for running the AC below 70 degrees F...

Yes to the first statement... I can not find a graph in this book...I mean the correct one... it is full of graphs.... sure it is there....but my first thought when you mentioned how low your ambient temperature was was whether any graph has cooling for that range.. I do think you are correct in that you have lost refrigerant since your charge.. which looked good to start with... What type system are you calling this ? Other than orifice tube... Are your controls type 2 or 3 ?

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/showthread.php?threadid=10414 http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#55

|

||||

|

||||

|

I found a leak here:

It's where the line leaves the receiver and runs to the OT holder. It's intermittent with temp and seems to only leak when the system is cooled off. It's actually leaking past one of the crimps so I'm going to have to re-do that hose. 1 out of 10 isn't bad plus I changed that elbow from a 90 deg to a 45 deg and back a couple of times when mocking it up so I may have nicked the inside of the hose or something  I've had the gauges on it several times plus I had some trouble connecting the hi side line a couple of times so I'm sure I lost some refrigerant that way as well. The controls are ACC II and I'm running a rebuilt aluminum servo. I think I need a new amp because the big resistors on both of mine are crusty and I've re-soldered them a couple of times. It'll work FINE when testing in the garage but after about an hour of driving I lose system response  After it cools off all seems to be well again so I guess I'll go with a rebuilt amp. You're really supposed to change the amp/servo together but I thought I'd get lucky... After it cools off all seems to be well again so I guess I'll go with a rebuilt amp. You're really supposed to change the amp/servo together but I thought I'd get lucky...I'll let you name it Greg

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD |

|

#56

|

|||

|

|||

|

I will wait till you get the bugs worked out...

I don't want to waste a good name on it and it wind up like ' Edsel ' ... LOL

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/showthread.php?threadid=10414 http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#57

|

||||

|

||||

|

So far I'm REALLY HAPPY with the way it turned out. I haven't done as much high temp testing as I'd like but it's Ga. It'll change

FYI: The shop that I paid to charge it only held vacuum for about 10 minutes. The gauge held "30" (don't remember 30 "whats") and they put 2 lbs in 8 oz at a time until the low side was 30 psi. I think there must still be some moisture in the system so I'm going to vacuum it myself and recharge. They found the leak, then lost it. I drove the car for a few days and the leak was gone but I can see tiny, tiny bubbles at the fitting. Like foam. Just a tiny bit of foam once it cools off and soapy water is sprayed on it. Gotta fix the leak, gotta pull a good vacuum. I think I have about 14 oz of oil in the system  I added 2 oz per component. (Condenser, drier, evaporator and accumulator) The compressor came with oil and warning stickers about draining it. From what I can gather, the 709 holds 6 oz of oil in the sump. So there must be PLENTY of oil in the system. I'll check the accumulator when I break the system down. If it's gooey saturated I don't think I'll add any more to the new one. I added 2 oz per component. (Condenser, drier, evaporator and accumulator) The compressor came with oil and warning stickers about draining it. From what I can gather, the 709 holds 6 oz of oil in the sump. So there must be PLENTY of oil in the system. I'll check the accumulator when I break the system down. If it's gooey saturated I don't think I'll add any more to the new one.Changing the accumulator (which has a filter) and changing the OT (another filter) should leave the system pretty clean. Anything else? I think that once I get these issues resolved it'll be OK. Cools like a mofo now

__________________

My occupational hazard bein' my occupation's just not around... 1980 300SD 1980 300SD |

|

#58

|

|||

|

|||

|

I don't even know what to say....

You totally rebuild your system changing it to exactly what you want it to be. No effort spared in redoing anything you feel is not right... Then you take it to some Rinky Dink shop and allow them to only pull a vacuum for that short a period of time ( clearly too short a time to boil out moisture ) AND Do not insist that they do a Pressure Leak Check before installing refrigerant ? The attention to detail on your fabrication end... then the lack of supervision of the shop is an amazing contrast to me.... I suppose it has value in showing others that AC work takes attention to detail and physics through the whole process ....but brings to mind questions about the preaching I , VStech and many others have done about the moisture removal and the need for pressure testing... Here is the scary part... what if it had worked ' just fine ' ( since you have no MB numbers guide to determine 'fine' ) ... and you just buttoned it up and went on to the next project ? ... Leaving moisture in there to make acid and start the immediate deterioration of the inside of your system ? How sad would that have been ?

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/showthread.php?threadid=10414 http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

#59

|

||||

|

||||

|

Quote:

It is over 2 hours from his house to my place Greg  . .

__________________

Jim |

|

#60

|

|||

|

|||

|

Jim, You are not saying he brought it to you are you ?

You are saying that to get to your place and have it done right is more than a two hour drive ? Greg

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/showthread.php?threadid=10414 http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

| Bookmarks |

|

|