|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

|

|

#1

|

||||

|

||||

|

Another update

For all of you who have purchased a Gen II kit, I have another update. I am planning on making another bracket to help secure the bottom of the compressor mounting plate. It will mount using longer bolts in 3 of the pan bolt holes, and nuts on the top. Another hole (1/2") is drilled in the compressor mounting plate .625 from each edge. Here is a look at the prototype:

Location of drilled hole:  The bracket is needed more for the 616 application, but I have prototypes made for both the 616 & 617 turbo (they are different). I am not sure if the 617 N/A has the same lower pan as the turbo. If it is different, I will need to make a third bracket. From now on, all of the plates will have the hole drilled in them, and the bracket should be available shortly. If you have a plate already installed, it is possible to drill the hole without removing the compressor. I will post here when the brackets are available, and send them to those that have already purchased a kit....Rich

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#2

|

||||

|

||||

|

Quote:

What's the issue you are having with the plate? Vibrations? Plate flexing? Does the Gen 1 have the same issue? .

__________________

1983 123.133 California - GreaseCar Veg System |

|

#3

|

||||

|

||||

|

I have not heard from anyone about any problem, but I found that on my 240 the belt was chirping regardless of how tight it was. There is less support on the lower part of the plate on a 616, so this new bracket fixed the problem. All of the 617 applications I have done have not had any problems. It may be that the piece of the block that sticks out just above the upper pan on a 617 offers more support. I am making brackets for both anyway, and drilling all the plates, not knowing what engine they will go on. I don't think the bracket will work on the Gen 1 plate, as the bolt would be right where the compressor mounting tab is. However, the new bracket could be welded in place for the Gen 1 applications if needed.....Rich

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#4

|

|||

|

|||

|

Rich,

I really appreciate your being pro-active on all these issues. This new bracket concerns me if it could crack the upper oil pan, since steel often wins against cast aluminum. I know M-B hung other things off that lip, like the high-pressure AC hose (seems silly), but it would be a major pain to deal with a crack there (must remove engine). I haven't installed your compressor bracket yet since my son hasn't returned with the car. I may look into welding a stiffener down the front of the plate instead, or maybe adding a rubber snubber that presses against the block to damp vibrations. I would rather risk the compressor plate than my upper oil pan. |

|

#5

|

||||

|

||||

|

Quote:

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#6

|

||||

|

||||

|

Quote:

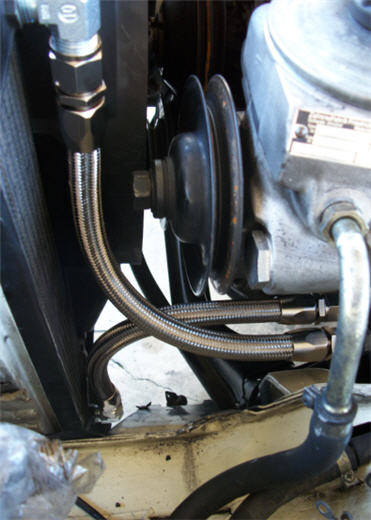

As I analyzed the problem, I was very concerned about the amount of the bracket that was cantilevered and the amount of stress and vibration that was present. I don't have the capability to do finite element analysis or anything other than "back-of-the-napkin" engineering, so I can't speak definitively. I also had a problem in that, I couldn't use the bottom adjusting solution because of space so I had to develop a belt adjusting strategy that could be accomplished from above. In fact I had to cut the bottom two inches of the bracket off. (My 617 is in a 107 chassis, so I have extremely limited space to work with.) My solution is to tie the outboard ear on the Sanden to the lower P/S bolt like this: ( I apologize for the picture - it was taken during mock up with my junk compressor and temp rods for mounting )  The adjusting rod is a 1/2" tube with heim joints on either end. I used a long 1/2" bolt with sleeves to keep the lower heim joint at the proper 90 degree position relative to the compressor. I needed to use a longer bolt on the P/S pump due to the additional width of the heim joint. The adjuster nut in the middle makes adjusting a snap using a crows foot wrench. Also, using this strategy puts the adjustment components in tension rather than compression.  This provides a pretty substantial triangulation which is illustrated in the following  If I were using an unmodified GenII bracket, I'd supplement the support using this strategy. The adjustment procedure would be as follows - double-check the tension on the P/S belt; loosen the bottom adjuster on the GenII bracket; adjust the A/C belt tension with the adjuster rod; snug up the bottom adjuster as backup. I've got over 5k miles on the setup and the only problem has been keeping the belt in adjustment. (I think this is mainly due to belt stretch due to using a cheap belt - my bad!).

__________________

Current Stable

|

|

#7

|

||||

|

||||

|

Quote:

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#8

|

||||

|

||||

|

Quote:

It's been so long since I did the oil cooler line mod, I forget how the original lines ran. And I should also state that I'm using an oil filter and lines off an SD (126) that may put the lines in a different relative position. I think the point I was trying to make is, that if someone wants to try to add some top support, the solution I found is one that works. And if they've got the fab skills to weld up an adjuster rod, moving the cooler lines an inch or two and modifying the support bracket should be within reach.

__________________

Current Stable

|

|

#9

|

||||

|

||||

|

Quote:

When I get them back, I will make up the kits and have them available (I will start a new thread).....Rich

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#10

|

||||

|

||||

|

I went to the fab shop today to pick up the rest of the parts (plates and tabs). I snatched a photo of the last of the plates being cut:

The new design incorporates slots in the plate so the tabs are welded on the back (photo posted when I get one ready). I am calling it Gen 2.1....Rich

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

| Bookmarks |

|

|