|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

|

|

#1

|

|||

|

|||

|

Quote:

|

|

#2

|

|||

|

|||

|

Sounds like a fairly promising method, I shall try it in a month and report back with results!

|

|

#3

|

||||

|

||||

|

I am too scared to try it this way, and I have valve adjusting down to about 30 minutes total anyway. I would also need to get the big wrench if I was to try it. I have never needed more than 2- 14mm wrenches (one custom bent, and one straight) to do this job. After doing a few, you get to be faster at it. I do one cyl at a time in the firing order. I only need to turn the crank 36 degrees each time, then adjust the next one in the firing order.

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#4

|

||||

|

||||

|

Valves will have a degree of runout, if only a thousandth or two. As you rotate the valve, you will feel a tight spot where you lose some clearance. This is where you want to adjust the clearances; at the tightest point. Otherwise, as the valve rotates, it will reduce clearance in the area that has the most runout.

All I have ever done on a 617 is point the lobe at the spray tube and adjust...

__________________

1978 300SD 'Phil' - 1,315,853 Miles And Counting - 1, 317,885 as of 12/27/2012 - 1,333,000 as of 05/10/2013, 1,337,850 as of July 15, 2013, 1,339,000 as of August 13, 2013 100,000 miles since June 2005 Overhaul - Sold January 25th, 2014 After 1,344,246 Miles & 20 Years of Ownership

|

|

#5

|

|||

|

|||

|

I forgot to try this method, though I want to and will soon.

-Unless anybody has discovered any negatives. No stripped valve stems, or anything to report?

__________________

1982 300CD Petrol/Black Leather |

|

#6

|

||||

|

||||

|

My first time adjusting valves. 2.5hrs taking my time to adjust and recheck. Used the regular way due to the fact I didn't have a wrench to hold the large nut. All 8 valves were tight. I did have a issue re-installing the valve cover. then found out the cam was in the wrong position not allowing the cover to slide by. once i rotated the motor it went right on.

Seems to start and run smoother.

__________________

2006 Jetta TDI DSG 320k miles 1997 Ford F150 325k miles 4.2L V6 "Work Truck" 2008 Tundra 225k miles 5.7L 1982 240D.....sold 1984 300D...Totaled OUCH! 1985 300D Turbo 222k miles "Dos" sold to 79Mercy 1986 300SDL 98K miles "The Beater"....sold 1987 190E 2.3 16v Euro spec 115K miles....sold |

|

#7

|

||||

|

||||

|

Quote:

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#8

|

||||

|

||||

|

I dunno about this. It would seem to me that jam nuts are designed to be tightened to prevent movement. And then loosened to allow movement. It's not that big of a deal really. Just adjust each valve as the lobe points to the oil rail and move on. Keep it simple. That's why the valve adjusting wrenches come in a set of 3. Use them

__________________

'70 F100 shortbed '82 Diesel Westy '83 Euro 300TD Curtlo Viper Yeti ARC Surly long haul trucker |

|

#9

|

|||

|

|||

|

I would have to agree. Any time saved will be long gone after you strip the threads on one of the valves.

__________________

'83 300D, 126K miles. |

|

#10

|

|||

|

|||

|

This is complete nonsense. It's been a few years, so hopefully you found another mechanic... Let's simplify:

Look at the design of the valve. Effectively, you have a threaded rod (valve stem) going through a hole in a cap that can spin (the part over the spring with the hex flats). You can rotate the cap infinitely, which rotates the entire valve as well. The only way to affect the position of the valve stem relative to the cap and the rocker is to turn the lower nut, which requires loosening of the upper one. If you rotate the locked valve nuts relative to the cap, spinning the entire valve, you are doing nothing. At best you are grinding the valve against the valve seat, which might knock some debris loose. Take a look at the design drawing. |

|

#11

|

|||

|

|||

|

Worked for me. The large spring retaining "cap" as you call it prevents the valve from rotating while you adjust the nuts. What else would the function of that third wrench be? Or am I misreading your protest?

__________________

1982 300CD Petrol/Black Leather |

|

#12

|

||||

|

||||

|

Quote:

Here are some pics and diagrams to help visualize. There is a key in the valve spring retainer and a key way in the valve stem and the two parts are locked together.

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#13

|

|||

|

|||

|

I kind of follow that approach, but only at the final tightening. If the gap is on the tight side, I swing the top wrench more (moves top nut down), or if slightly loose I swing the wrench on the lower jam nut more. I check the gap when done and sometimes loosen and repeat. The way the OP describes it sounds like the jam nut isn't tight when starting the process. Probably takes 20 min to adjust all valves, after the valve cover is off. I have done it ~5 times.

I wonder why so much fuss in many posts about special bent wrenches and such. I have always used regular open-ended wrenches, though the lower one is short enough to swing between the injector tubes as I recall. It is from a cheap HF kit of all open w/ say 15 mm & 16 mm on one wrench. On the few occasions when I had the injector tubes off, that is a great time to adjust valves, but I sure wouldn't remove them for that task.

__________________

1984 & 1985 CA 300D's 1964 & 65 Mopar's - Valiant, Dart, Newport 1996 & 2002 Chrysler minivans |

|

#14

|

|||

|

|||

|

....total confusion

I realize this is a fairly old thread. About to do my valves, thought I'd review, now confused.

Not so sure about this procedure per the original post...a couple inconsistencies I found: (please keep in mind, I may be having a "senior" moment) The poster states if the clearance is too "tight", turn the nut "counterclockwise". Unless these are reverse thread (never heard mention of that here), counterclockwise would move the adjuster closer to the rocker, thereby making the clearance smaller or the tolerance tighter, by closing the gap.....right? He then states if the clearance is too wide, or loose, turn the nut "clockwise" to close the gap and make the clearance tighter. Again, clockwise would open the gap even further, making the clearance bigger or more loose. I guess my confusion is with which way to turn the adjusting nuts? Logic tells me "CCW" will close the gap and "CW" will open the gap. Am I missing something here? Used to adjust valves "all the time" on my and my buddies VW's "back in the 70's"...we had a bunch of em. I realize this is a little different, but the principle and end result are the same. (guess I'm showing my age...  ) )

|

|

#15

|

||||

|

||||

|

Quote:

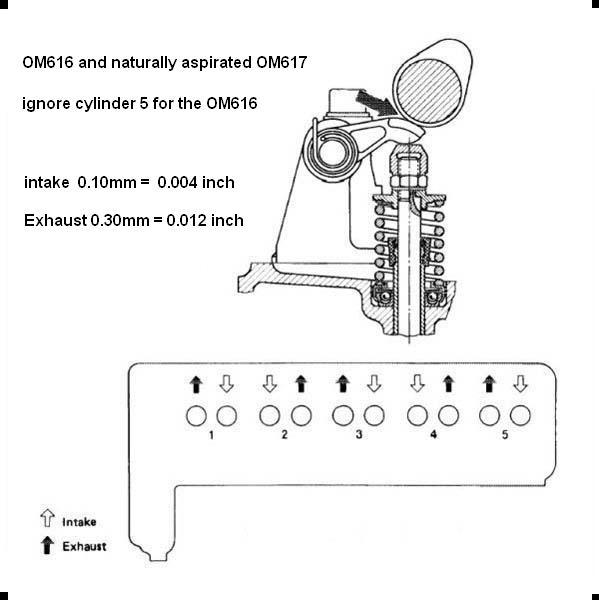

In this case the adjusting Nut and Lock Nut are threaded onto the Valve Stem and the Rocker Arm which has no adjustment and the Camshaft are above the Adjusting Nut and Valve. You will quickly understand when you see it. The first pic is just to show the relationship of the parts. The pic on the right is to show the Valve Spring Retainer that you may need to hold to keep from rotating until the Nuts are loosened. The original Valve Adjusting Wrench set has a 3rd Wrench for that. However, there is alternative methods for holding it but don't put too much force on it. Once the Nuts are loose it is not an issue. When I did my first valve adjustment I had to use the 3rd wrench on 2 of them.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

| Bookmarks |

| Thread Tools | |

| Display Modes | |

|

|