|

|

|

|

|

|

|

|

|

|

|

#106

|

||||

|

||||

|

Quote:

PeachPartsWiki: Calf. to Fed. Emissions Conversion I'm not sure about bigger, but definitely different...

__________________

Current Stable

|

|

#107

|

||||

|

||||

|

Thanks Mach4 for the info.

I'm in the throes of my own 107 TD conversion right now and don't want to hijack this thread but am interested in what the verdict would be re: this question... On the driveshaft alignment problem I have the option of two different rubber joints (or to go for a constant velocity type but that's another story). Type #1.. this is as fitted to the 107 before any engine mods. It has eccentric centers and the rubber around the bolt sleeve is scalloped out to give quite considerable movement.  Type #2.. this is from a W124 320TE with Getrag 5speed box which is the one being used in the conversion. The steel sleeves in this are solid moulded to the main part.  Now! if the joint is mounted in a vice like this...  Type #1 can be deformed from it's static position by a quite considerable amount and with little effort: suggesting that this is the way it is designed to be. Type #2 is to all intents and purposes immovable and would need to be mounted with the flanges in almost perfect alignment. In fact it is so strong at resisting deflection it suggests to me that if all were not perfect the gearbox rear bearing might suffer. What are the panels thoughts on this? |

|

#108

|

||||

|

||||

|

Quote:

(In case you don't know you can now access the FSM via Mercedes star tek Mercedes Startek have done the right thing - to help you do the right thing! http://www.startekinfo.com/StarTek/outside/11883/PROGRAM/Chassis/41-050.pdf Is the direct link to the PDF you guys need - scroll down to page 3) I guess they were added for comfort - I haven't heard of the cars fitted with the earlier system failing. However - the 107 is shorter than the W124 - perhaps the stiffer flex discs are better for the longer prop shafts? I mean you don't want a long wanga wanging about down there do you?

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#109

|

|||

|

|||

|

happy new years folks..

Anyway,the flex disc is to allow for the unibody to flex and to allow the engine and trans to exit under the car in the event of a headon smash,not for misalignment of the trans  Same reason the engine mounts collapse every 10 years,they are designed to rip away. Same reason the engine mounts collapse every 10 years,they are designed to rip away. Because I own a 6.3 which eats flex discs I can say from experience that they must be well within specs if you want any life from them.  Does the use of the spacers place the crank center l inline with the center bearing ? On the M100 conversion it dropped it 50mm below the centerline which forced the issue and we installed two uni-joints. Very big ones as it happens . The car has been driven to 280KPH on the autobahn without a problem. |

|

#110

|

||||

|

||||

|

Quote:

Quote:

With all the fitment issues solved, I can now focus on getting the engine cleaned up and all the little bits installed and the details in the engine compartment taken care of and ready for a final install. It feels like it's getting close, but I've been around long enough to know that the last 10% of any project takes 90% of the time!

__________________

Current Stable

|

|

#111

|

||||

|

||||

|

the last 10% of any project takes 90% of the time

This is somewhat how it is with a building too. As a building nears completion the details such as installing wires in conduit, finishing off plumbing installation, painting, trim carpentry do not impact the overall picture in big dramatic visual ways so the client always thinks there is nothing happening when we get to this point.

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#112

|

||||

|

||||

|

Today was mostly a junk yard day picking up what bits I could find and doing research on other aspects of the project. There was a 450SL out there that donated one of it's tie rods to the project.

The first thing I noticed when I crawled under the car was the failed control arm bracket on the subframe.  This common failure can be extremely dangerous and was the reason for a major subframe recall on the part of Mercedes. (Strangely it only covered the 450SL and not the 380SL) When I had the subframe out of the car one of the first things I did was to fabricate and install the reinforcing brackets on the mounts. The weight and vibration of the diesel in the vehicle make this a must for anyone doing this kind of a conversion. Cheap insurance!

__________________

Current Stable

|

|

#113

|

||||

|

||||

|

What a great project. Thanks for posting so much detail. Like some other diesel heads this is a dream project for me too. Looking forward to seeing the finished product!

__________________

H.D.B. OBK #45 ----------------------- '75 W115 240D, wife's dd, 197K ........'75 W115 300D, my dd, 245K .. .. ..........'82 W126 300SD, the 'someday' project |

|

#114

|

||||

|

||||

|

Quote:

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#115

|

||||

|

||||

|

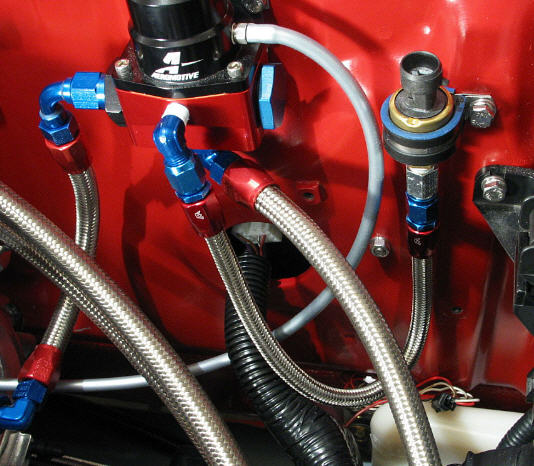

The main focus for today was the proof of concept of the idea of brazing on AN hose fittings on the Mercedes metric pipe as a way of transitioning to mil-spec hoses for oil and fuel. I went down to the hangar today to get checked out on the clubs oxy-acetylene equipment. Here is the result of the test. My oil cooler fittings are in great shape so I just cut the hose off and will braze on the fittings. (Eventually, I hope to pick up an oil cooler at the PNP and test cutting off the metric fitting and drilling and tapping the cooler to be able to go direct, eliminating one connection.) I'm using the same exact fittings on the other end of the hose to connect to the remote oil filter.

These are the kinds of hoses I intend to use - mil-spec AN fittings with high pressure stainless braided hose.  The other project was to get the throttle firewall bracket installed. First step was to cut off the existing bracket.  Then I needed to open up the existing hole. I used the largest step drill I could find (1-3/8") and still needed to clearance the back of the bracket slightly.  This was where I needed to be based on the trial fit...  And this is where it ended up.  I may need to extend the throttle linkage a bit, but it's close. There may be enough adjustment at the other end.

__________________

Current Stable

|

|

#116

|

||||

|

||||

|

Great looking work!

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#117

|

||||

|

||||

|

question

I was reflecting on this concept yesterday after seeing an SL drive by. I realize this is a bit off topic but how will the gross weight contrast before and after between car platforms?

I wonder if the diesel engine will be significantly heavier and also how that compares to the gross vehicle weight of a 300D compared to the SL body/chassis. If the latter is lighter, would you be expecting higher gas mileage than the W123 platform?

__________________

1979 300D 220 K miles 1995 C280 109 K miles 1992 Cadillac Eldorado Touring Coupe 57K miles SOLD ******************** 1979 240D 140Kmiles (bought for parents)  *SOLD. *SOLD.SAN FRANCISCO/(*San Diego) 1989 300SE 148 K miles *SOLD |

|

#118

|

||||

|

||||

|

The weight difference will depend on which 107 you use. The earlier cars had iron blocks so the weight will probably be very similar to a diesel. the 380s and up had all alloy engines which I will guess are lighter than a diesel.

The factory weight of an sl is very similar to a sedan with the same motor.

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#119

|

||||

|

||||

|

Quote:

My Corvette gets 33MPG on the open road, so I'm hoping that the SL will get 30 or so under the same conditions considering the factors of weight (a negative), diesel power (a positive), transmission (a negative) and aerodynamics (close). We'll just have to see.

__________________

Current Stable

|

|

#120

|

|||

|

|||

|

the oil filter housing on the om617 from a W123 is different than the housing from a W126. its possible that using the other housing may work for you. I remember having clearance problems with the oil filter housing when switching an engine from a 300d into a 300sd and I had to change the housings.

|

|

| Bookmarks |

|

|