|

|

|

|

|

|

|

|

|

|

|

|

|

#1

|

||||

|

||||

|

380SL Diesel Conversion Project

I'm in the process of putting an OM617 engine in a 380SL. Both the 380 and the 300D donor vehicle are 1985 models.

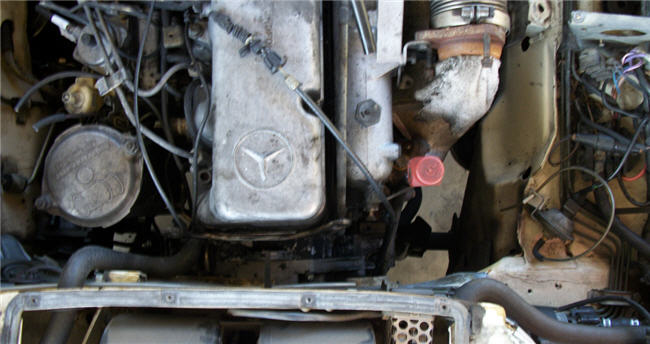

I've been busy doing lots of research and pulling the engines from both vehicles and getting ready for the swap. Everything I've found says the swap should work, but the actual data on existing swaps is not very specific. Opinions vary widely but common conjecture is that some combination of mods to the subframe, motor mounts, adding a hood scoop, fabricating spacers to the subframe, remoting the oil filter, changing A/C compressor etc are required, but nothing concrete. Today I dropped the OM617 into the 380SL for a trial fit and here is what I found. It fits.... with some qualifications.  Looks pretty good too. And yes, the hood closes with clearance.  There is plenty of room in the rear, and the radiator and fan fit really nicely in the front.  There is decent clearance for the front of the pan but some potential problems with the rear.  But there is one significant problem, and that is interference between the steering box and the oil filter housing. I had a hunch this was going to be a problem, but fortunately there is a straightforward solution and there is plenty of room on the left side of the engine bay. The orange arrow shows where the filter is hitting the steering gear and preventing the motor mount from swinging in the direction of the red arrow to allow the engine support arm from dropping into the motor mount.  In this picture the right engine arm is grounded in the motor mount recess, so the net effect is that the engine rear is cocked in the compartment to the left and the transmission is well right in the tunnel. (If you look closely at the first picture, you can see the engine cocked to the left). I'm using motor mounts from a 1975 300D which so happens to use the same subframe as the R107. The next step is to jack the engine slightly, pull the oil filter housing and actually secure the left mount in position and bolt up the transmission mount to get final clearances on the pan. Preliminary assessment shows that the drive shaft appears to be the right length. I don't yet know if the flex disc is the same, but with any luck it will be a simple bolt up. I'm guessing that there will likely be some minor notching of the rear subframe cross member that will be prudent. (I think the upper oil pan is different between the '75 and my '85 and that is the difference, but won't know until everything is in final position) When I mocked up the engine on the subframe out of the car, it was obvious that the R4 compressor wouldn't clear the upper control arm mount, so I was already planning on using a Sanden compressor for A/C. One other thing that doesn't quite fit is the radiator overflow. I'm also planning on filling the engine and transmission mounts with urethane to make sure there will be no adverse movement of the engine as the mounts age and sag. This should eliminate any clearance issues developing as the mounts age and also eliminate the need for engine shocks at the expense of a little harsher ride. (Fabricating engine shock mounts would be tricky) Last edited by vstech; 12-06-2011 at 09:30 PM. |

|

#2

|

||||

|

||||

|

I once swapped a euro intake manifold into a 73 BMW which took a four barrell carb. The intake was used in Europe without a brake booster so there was interference. I eventually ground some material off the manifold corner and put three or four washers between the motor mount and the engine arm. That tilted the whole motor over a bit and gave enough clearance. You might be able to do something similar. I know you can do a remote filter but those always make me nervous.

Great idea!

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#3

|

||||

|

||||

|

Quote:

I'm resigned to doing a remote oil filter. Thanks for the idea. |

|

#4

|

||||

|

||||

|

Would there be a different steering box that would be narrower and bolt up with little to no modification?

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#5

|

||||

|

||||

|

Subframe needs to be notched

Today I used the cherry picker to lift the engine to be able to get at the oil filter housing and removed it. I then dropped the engine into position to check for clearance on the sub frame. Both engine support arms are positioned properly in the motor mounts and I was able to bolt up the transmission mount into position (albeit with the help of a lever to move the transmission into a centered position to be able to start the bolts)

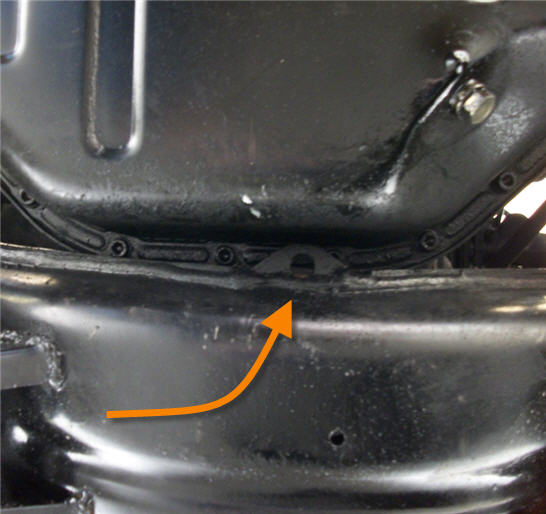

It should have centered right up and the fact that it didn't pointed to something hitting and indeed I found that the oil pan is hitting against the subframe as shown here.  Here's another view from a different angle.  A little clearanceing here might be beneficial but probably not necessary.  And I'll need to trim off this little tab to keep from puncturing the lower pan.  All in all, some fairly minor subframe mods to get the clearance needed. Last edited by vstech; 12-06-2011 at 09:34 PM. |

|

#6

|

||||

|

||||

|

That all looks very good.

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#7

|

||||

|

||||

|

I would be seriously clearancing that sub-frame, leaving at LEAST a half inch at rest, you know how these engines move around when under load or in reverse..how is the clearance between the turbocharger and the car? still room for exhaust?

__________________

RIP: 80 300SD RIP: 79 450SEL 2002 E430 4matic (212,000km) 2002 ML500 'sport' ____________________________ FACEBOOK: PANZER450 |

|

#8

|

||||

|

||||

|

Quote:

I plan on getting as much clearance as possible - as you point out, shaking and normal movement can be significant, and collapsing motor mounts over time can easily eat up 1/2" or more of clearance. (Which is why I plan to fill my motor/transmission mounts with urethane... as well as the subframe mounts as well) Quote:

But in the top view you can see how much room there really is for the exhaust. (That's a rag stuffed in the turbo outlet)  The radiator overflow tank may be another story though. The tentative plan is to use a different one and move it forward into the slot previously occupied by the windshield washer reservoir both for clearance and to get it away from the turbo heat. I was at the junk yard today and kind of kept my eye open for a metal overflow tank to avoid the heat issue, but, no joy. I guess those haven't been used in forever. Last edited by vstech; 12-06-2011 at 09:35 PM. |

|

#9

|

||||

|

||||

|

Progress

Spent a lot of time over the last couple days trying to figure out the best solution to remoting the oil filter to address the clearance problem with the steering gear.

My first thought was to go with a third party remote, but decided that that route was just too much trouble. I'd have to engineer not only a decent adapter, but figure out a set of filters that would do as good as the stock dual purpose full flow and bypass filter on one. And then there is of course the issue of setting up a thermostatically controlled oil cooler solution and a clogged filter bypass function as well. There aren't a lot of choices for mounting either. My solution is to use the stock filter and move it up about 4 inches and outboard to the fender above the steering gear mount. There is no good attach points on the engine, so I'll mount it on the fender well. I've already fabbed the filter mounting plate and the fender bracket but got shut out from making the engine remote plate because the metal store was closed for the holiday. I'll then use AN10 aircraft fittings and steel braided high pressure line to connect the two (and probably AN6 fittings for the bypass filter outlet to the engine pan. I bought an extra filter housing top in case I decide I need to tap it for a stud for an extra support bracket (or possibly weld one on) to stabilize the top of the filter housing (that housing is big!) No pictures yet, but I will as soon as things get welded up. This weekend was half price at the JY so I got a starter solenoid (for manual glow plugs) and a vacuum solenoid (for manual shutdown). Also scored an instrument cluster with a mechanical oil pressure and a mechanical speedo, so that only leaves the tach as a potential problem. Also got some extra oil cooler line fittings that I'll need to fab up the new oil lines. The plan here is to braze on AN10 fittings to the hard line as transition to steel braid high pressure line. It's interesting, as this project takes form you start to notice things. For example, in this forum photo of another project, there is no oil filter in evidence, so obviously the builder had the same clearance issue, but apparently elected to go with a non-Mercedes solution for oil filtration and mounted it down out of sight somewhere.

Last edited by vstech; 12-06-2011 at 09:37 PM. |

|

#10

|

||||

|

||||

|

could you heat the area and beat it in a bit? or would that weaken it?

__________________

RIP: 80 300SD RIP: 79 450SEL 2002 E430 4matic (212,000km) 2002 ML500 'sport' ____________________________ FACEBOOK: PANZER450 |

|

#11

|

||||

|

||||

|

Quote:

|

|

#12

|

||||

|

||||

|

Just a general comment.

Mind you I have never done a 617 into 107 swap. The 107 was offered in Europe with the 110 engine. I have always said if a 110 fits a 617 should fit (in a general sense). Of course the 110 is not turbocharged and it has a different oil filter arrangement. As offseting facts, the 110 is a cross flow head so it has a pretty bulky intake manifold setup on the drivers side of the engine. The oil filter on the 617 when it was installed in the 115 chassis was a down loader like the 110 so it might be possible to use one of those on your 617. Just a thought. It looks like you are making some really good progress!

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#13

|

||||

|

||||

|

Maybe a solution

Quote:

In that same vein, is it possible that the oil pan from that same engine would work on the later OM617.952? If so, that would solve the subframe clearance problem as well? I'm already using the engine support brackets from a 115 and the other bits should still be there. It would be nice to keep things as stock as possible. |

|

#14

|

|||

|

|||

|

Quote:

__________________

Strelnik Invest in America: Buy a Congressman! 1950 170SD 1951 Citroen 11BN 1953 Citroen 11BNF limo 1953 220a project 1959 180D 1960 190D 1960 Borgward Isabella TS 2dr 1983 240D daily driver 1983 380SL 1990 350SDL daily driver alt 3 x Citroen DS21M, down from 5 3 x Citroen 2CV, down from 6 |

|

#15

|

||||

|

||||

|

The oil pan from a non-turbo engine will not work on a turbo engine. I received numerous reasons why when I asked the question. Turbo drain lines etc... I can't remember why else it wouldn't work but it was clear.

__________________

1981 300TD "The Green Lantern" 1980 300TD 1983 300D Euro "China Cat" |

|

| Bookmarks |

|

|