|

|

|

|

|

|

|

|

|

|

|

#91

|

||||

|

||||

|

I'm trying to document in as much detail as possible what it takes to do this kind of a swap. Not to say that I'm doing it the "right way", but at least I hope to show that it is possible and provide a map for others to build on. There's a long way to go, but I now believe everything is do-able, and relatively straightforward.

Let me know if I can answer any questions...

__________________

Current Stable

|

|

#92

|

|||

|

|||

|

You are an incredably talented guy and fabricator. You just blew the na-sayers out of the water. wonder where they all are now?

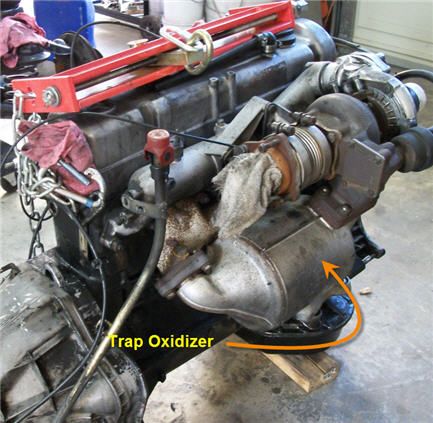

I think you mentioned early on that you were going to use the 85 Cali intake/exhaust with the Turbo sitting up higher for clearance issues. Are you going to eliminate the trap oxidizer and install a by-pass pipe? Using a 78 or 79 W116 300SD intake/ex manifold doesn`t have the EGR, and would clean up things. but it would all sit lower. You are right, looks like it belongs there. I would like this set up in a SLC. Charlie

__________________

there were three HP ratings on the OM616... 1) Not much power 2) Even less power 3) Not nearly enough power!! 240D w/auto Anyone that thinks a 240D is slow drives too fast. 80 240D Naturally Exasperated, 4-Spd 388k DD 150mph spedo 3:58 Diff We are advised to NOT judge ALL Muslims by the actions of a few lunatics, but we are encouraged to judge ALL gun owners by the actions of a few lunatics. Funny how that works |

|

#93

|

||||

|

||||

|

Quote:

Now once I'm inspected and get the title changed from gas to diesel, I can play all the games you other guys play with your setups.  You can see how big that trap-ox is here

__________________

Current Stable

|

|

#94

|

|||

|

|||

|

I hear you loud and clear. forgot about CARB etc....

My 85 300D had all that junk, at higher altitudes, you will have no performance or power. I think my 80 240D could have out performed it, UP HILL.  I kept all the Cali junk, and have a spare cali 85 engine. Charlie

__________________

there were three HP ratings on the OM616... 1) Not much power 2) Even less power 3) Not nearly enough power!! 240D w/auto Anyone that thinks a 240D is slow drives too fast. 80 240D Naturally Exasperated, 4-Spd 388k DD 150mph spedo 3:58 Diff We are advised to NOT judge ALL Muslims by the actions of a few lunatics, but we are encouraged to judge ALL gun owners by the actions of a few lunatics. Funny how that works |

|

#95

|

||||

|

||||

|

That trap ox is like a huge goiter on the side of the lovely 617 motor!

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#96

|

||||

|

||||

|

I finally got confirmation of my valve cover to hood clearance. Up until now, all I knew that it cleared.

I built a little clearance gauge out of some tape and a piece of paper and a tie wrap. The paper allows the tie wrap to slide and not stick to the adhesive on the tape. I set the gauge at about 1.5 inches and then closed the hood and measured. (I was almost afraid to look) But as you can see there is plenty of clearance - enough so I can add a bit of insulation to the hood without any worries. And could shave about a 1/16" off my subframe shims and still be ok.

__________________

Current Stable

|

|

#97

|

||||

|

||||

|

When you get the car all legal, you are invited to go on one of our So. Cal. cruises. We would love to have you along with us. Check out: Home - Mercedes Benz Enthusiasts Group

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#98

|

||||

|

||||

|

This beast is going to have to be re-badged when it's done... would it then become a 300SLD?

__________________

RIP: 80 300SD RIP: 79 450SEL 2002 E430 4matic (212,000km) 2002 ML500 'sport' ____________________________ FACEBOOK: PANZER450 |

|

#99

|

||||

|

||||

|

For the benefit of your British readers

what is a trap-ox and CARB? what is a trap-ox and CARB? Is that the standard fit 617 turbo, it looks huge?

|

|

#100

|

|||

|

|||

|

I have seen a diesel 107 before ...in India .

In your situation i wouldn't have used a car sump but hunted down a G Wagon sump which is a different shape and in one piece. They have a lot more clearance on the rear where yours is hitting the crossmember. I have also helped a friend install a M100 6.9 into a 107 and the crossmember was dropped as you have done. This caused a major problem ,the crank centerline was out of line with the centerbearing on the drive shaft . Because the shaft must run straight with no bends you have to either keep the crank center line location correct or drop the center bearing and diff to keep everything in line . DO NO TRY TO USE THE FLEX DISCS AS A MEANS OF RUNNING THE SHAFT THROUGH A BEND. You will have to either lower the center bearing to realign the shaft as it comes off the rear of the trans or fit a uni joint to the trans . There is a SAE yoke which bolts into the rear of the merc trans to eliminate the flex disc spider. I wouldn't recommend this approach though because you will have harmonics transferring into the car. I am not sure if mercedes is still selling separate types of engine mounts now as most I buy are the same part ,supplied for all types of engines. The big secret to stop too much engine movement is to substitute one of the engine shocks with a belt tensioner shock from a OM 603 etc. |

|

#101

|

||||

|

||||

|

Quote:

C.A.R.B. is the division of motor vehicles dealing with emissions in California. carb,california air resources board,jobs,employment opportunities,personnel,air pollution,smoke management,mtbe,gasoline,diesel,air quality management,air ...

__________________

John HAUL AWAY, OR CRUSHED CARS!!! HELP ME keep the cars out of the crusher! A/C Thread "as I ride with my a/c on... I have fond memories of sweaty oily saturdays and spewing R12 into the air. THANKS for all you do! My drivers: 1987 190D 2.5Turbo 1987 560SL convertible 1987 190D 2.5-5SPEED!!!  1987 300TD 2005 Dodge Sprinter 2500 158"WB 1994GMC 2500 6.5Turbo truck... I had to put the ladder somewhere! |

|

#102

|

||||

|

||||

|

Quote:

Great work! Great work!

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#103

|

||||

|

||||

|

Quote:

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#104

|

||||

|

||||

|

I would definately do some badging saying diesel just in case someone might be tempted to fill with gasoline in the future.

__________________

[SIGPIC] Diesel loving autocrossing grandpa Architect. 08 Dodge 3/4 ton with Cummins & six speed; I have had about 35 benzes. I have a 39 Studebaker Coupe Express pickup in which I have had installed a 617 turbo and a five speed manual.  [SIGPIC] [SIGPIC]..I also have a 427 Cobra replica with an aluminum chassis. |

|

#105

|

||||

|

||||

|

Quote:

Sump: Finding a G-Wagon sump here would be next to impossible. I'm happy with the current sump as it gives me the clearance I need with minimal adjustments Alignment of engine crank centerline with driveshaft centerline - I have maintained almost perfect alignment because I have made two adjustments each counter to the other. If we consider that our point of reference should be the chassis since both the rear end and the center bearing and the transmission mount are all bolted directly to the chassis (albeit with some rubber dampers in between, but we can pretty safely ignore that) then we have only one variable and that is the position of the front motor mount relative to the chassis. (Parenthetically, since I am using stock MB motor mounts from a vehicle that uses the same 107 sub-frame, and the stock motor mounts, the position of the motor relative to the subframe is not changed) So my adjustments are to move the engine up .5 inches (to gain one-half inch of clearance from the engine sump to the subframe) and down one-half inch (technically .6 inch) to maintain clearance between the rocker arm and the hood. So the net result is that the engine is in the same relative position to the chassis as stock, and by extension the same relative position to the driveshaft, center bearing and rear end. Flex Disks - My understanding is that the flex disks are designed to operate up to 2 degrees out of absolute alignment. So assuming for the moment that I didn't make the countervailing adjustments but just made one adjustment of 1/2 inch, either up or down, we can check to see whether we would still be within spec. The distance between the transmission mount and the motor mount is 36". Applying a little trig, a half inch movement up or down at the engine mount would give us a tangent of .0139 which is .8 degree. A full inch would be 1.6 degrees and we could go all the way to 1.26" and still be within spec. And that makes sense, because there are a lot of people driving around with collapsed motor mounts which is about 1.25 inches (coincidence?? or German engineering) But that's not all, remember that the subframe is also mounted in rubber bushings that can, and do, collapse, maybe even at close to the same rate and amount. So if this happens the engine actually tends to stay in the same relative position as the rubber around it ages. (Which also might be a reason to always change the subframe bushings and engine mounts at the same time) Because I wanted to take engine mount, subframe mount and transmission mount collapsing out of the equation for maintaining clearance, I filled them with urethane. (We'll see how much additional vibration this creates and whether it is acceptable when I get this thing on the road) Tensioner - Your idea of using a belt tensioner as an engine shock absorber is interesting. Can you post pictures?

__________________

Current Stable

|

|

| Bookmarks |

|

|