|

|

|

|

|

|

|

|

|

|

|

#16

|

||||

|

||||

|

Quote:

I'd be interested in knowing how you got the stock sensors to work.

__________________

Current Stable

|

|

#17

|

|||

|

|||

|

Quote:

But anyhow - is there no internal governor in the Bosch IP pump? That would be very different from my other Diesel experience but I sure don't claim to know much about these pumps. It would be cool if one of the pump savvy guys would chime in here. Maybe Greazzer? Dan |

|

#18

|

||||

|

||||

|

Here is what I did : EngineSystemsManagement

My video in action. http://youtu.be/yFyMZ4urR9U Tach is not so easy to do, its a VR not a hall effect sensor. My only real concern is overvoltage. I've had the tach plug hanging out of the cluster for a while now wiating for some voltage readings and just haven't had time/interest. Too many house chores. Using the stock boost sensor is def the way to go IMO. Be careful of ground looping your EGT. I spent days cursing because it would work when powered off the laptop but not the engine. Like you I had high hopes of using my android for a display using BT for comm, but at the end of it all an LCD was way easier and more sensible. I still have the BT shield, probably going to use it to make a nest like tstat for the house. I don't think your choice of arduino's is great, not nearly enough pins.

__________________

http://superturbodiesel.com/images/sig.04.10.jpg 1995 E420 Schwarz 1995 E300 Weiss #1987 300D Sturmmachine #1991 300D Nearly Perfect #1994 E320 Cabriolet #1995 E320 Touring #1985 300D Sedan OBK #42 |

|

#19

|

||||

|

||||

|

Quote:

I don't think I'll have any trouble with pins on the Arduino ProMini. Unless I'm missing something (entirely possible) I'll need 2 digital pins for the EGT and one analog each for temps and pressures. The BT takes 2 digital, so that's a total of 4 digital and 5 analog. I've got 12 digital (plus tx and rx) and 8 analog pins on the ProMini. All the same pins as the Uno R3. Edit: Just remembered that the temp sensors use 1-Wire to communicate, so all the temp gauges combined use only one pin. So as currently conceived the system would take 5 digital and 1 analog.  There is some good info on the tach input that should be helpful here - Quick Fix: 1985 w123 Tach & A/C after EGR Failure The logic for using the phone as a display is

__________________

Current Stable

Last edited by mach4; 01-24-2014 at 01:48 PM. Reason: add image and info |

|

#20

|

||||

|

||||

|

What are you going to do the EGT with?

RE LCD vs BT, I had tge BT working but decided I really ddint want to have my phone always on always working etc. What I do need is EGT ALWAYS on, Dunno. Keep us posted!

__________________

http://superturbodiesel.com/images/sig.04.10.jpg 1995 E420 Schwarz 1995 E300 Weiss #1987 300D Sturmmachine #1991 300D Nearly Perfect #1994 E320 Cabriolet #1995 E320 Touring #1985 300D Sedan OBK #42 |

|

#21

|

||||

|

||||

|

Here's a quick update on the project.

One of the big accomplishments was getting the application compiled, uploaded and actually running on the HTC Incredible Android phone. I say big accomplishments because it was one of the most frustrating and tricky things I've done. Just lots and lots of Googling, trial and error and luck. It's actually quite responsive running on the phone. Starting to work on sourcing the sensors and thinking through the mounting issues a little more. I've also made significant progress on the Android app. Here's a screen capture of the current application running in demo mode on the PC. I anticipate having lots of different screens available and this just demonstrates the options and capabilities.  https://www.youtube.com/watch?v=KYmL555em38

__________________

Current Stable

|

|

#22

|

||||

|

||||

|

The EGT will be running on the Android. Remember, the Android is an old one that is no longer used as a phone, so I'll literally be just using it as a Bluetooth receiver and a presentation screen. My iPhone will be providing phone/navigation/Pandora capabilities as always.

__________________

Current Stable

|

|

#23

|

||||

|

||||

|

__________________

Current Stable

|

|

#24

|

||||

|

||||

|

Quote:

__________________

http://superturbodiesel.com/images/sig.04.10.jpg 1995 E420 Schwarz 1995 E300 Weiss #1987 300D Sturmmachine #1991 300D Nearly Perfect #1994 E320 Cabriolet #1995 E320 Touring #1985 300D Sedan OBK #42 |

|

#25

|

||||

|

||||

|

Quote:

__________________

Current Stable

|

|

#26

|

||||

|

||||

|

Here's a quick project update.

I've been fighting with the bluetooth connectivity for days. This is one of the most ill documented things, not to mention complex I've ever encountered. One would think that it would be a relatively common thing to do data acquisition on an Arduino and pass the data wirelessly to an Android device, but alas it's not. There are lots of examples of controlling an Arduino from an Android by passing single bytes of data, but almost nothing the other way around, particularly using actual data strings. I've finally got the Arduino passing data strings to the Android relatively reliably. 85 - 90% of the data coming in is good and fortunately I have a way that I can easily recognize the bad data and discard it. If I look at the raw data, it's being received 100% reliably, so there's something with the code that's dropping data. It think it's a timing thing, as what finally got things working was putting in some arbitrary delays. I'm sure that someone out there, will come up with some better code that will make things a lot better. The way things are currently configured, I'm sending 4 readings per second, which is entirely adequate for temperatures and pressures. If I were attempting to read and present rpms for example this would not be adequate. Up until now, I wasn't sure if I would be able to get a bluetooth signal from the engine compartment to the passenger compartment. Today I took my breadboard Arduino and stuck it in the front of the engine compartment where I intend to mount it, turned it on and closed the hood. I booted the Android phone into the skeleton application from the normal position in the cabin and was able to read the data stream coming in. The range is not all that great - moving toward the back of the car, I quickly lost the signal, but moving back to the drivers seat provided a very solid signal. I can now confidently order the rest of the sensors and get the Arduino coded up to supply real data and the Android parsing the incoming data and passing it to the "gauges" part of the program. More to come...

__________________

Current Stable

|

|

#27

|

||||

|

||||

|

While my experience around the lack of documentation was similar, once it was working it was solid as a rock. What baud are you running at? Did you look at the android bluetooth chat samples? Thats really the easiest way to go. I spent a month dicking around with amarino, boy was that a waste of time. I was pushing full throttle on whatever baud I had it running at (which now escapes me, I remember it being part of the puzzle).

Did you write your own protocol? I did this, picked some random chars for a header and then packed all the data in behind it. Why would you put your arduino in the engine compartment? It is far better off in the dash somewhere IMO. How are you going to protect it from the elements?

__________________

http://superturbodiesel.com/images/sig.04.10.jpg 1995 E420 Schwarz 1995 E300 Weiss #1987 300D Sturmmachine #1991 300D Nearly Perfect #1994 E320 Cabriolet #1995 E320 Touring #1985 300D Sedan OBK #42 |

|

#28

|

||||

|

||||

|

Quote:

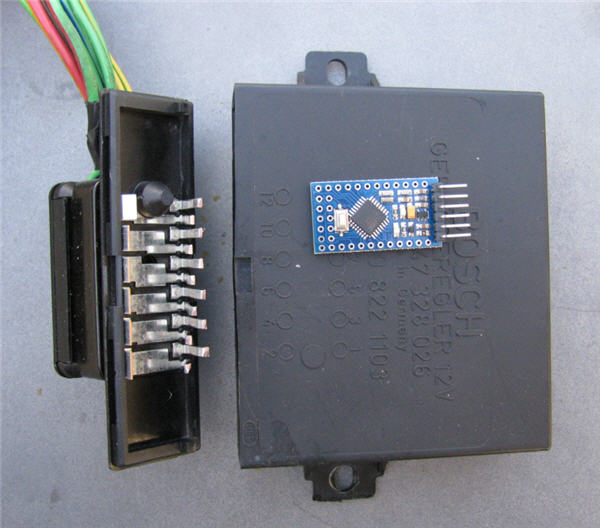

The reason to have the Arduino in the engine compartment is to avoid having to run any wires to the cabin. Also makes wiring up the sensors a whole lot easier. I'll be packaging the Arduino in a sealed relay box (see below) and hook up all the external wires through a standard MB plug. Since the box is plastic the bluetooth module can be mounted inside with the rest of the electronics. The Pro-Mini is shown for scale.  I should only 10 of the 12 plug wires available - 12v power and chassis ground, signal and ground for temp sensors (1-wire interface), two wires for EGT and two signal wires and a shared power and ground for the boost and vacuum sensors - 10 wires.

__________________

Current Stable

|

|

#29

|

||||

|

||||

|

This is an interesting project, so I will be monitoring this thread. Most of the technical jargon is way above my head, but the whole concept is so very interesting, that it should be fun to watch the progress. BTW, I will have the first Trap-Ox bypass pipe finished soon (for those that don't know, I have Paul's fixture). If you need another pipe, let me know. I am also toying with the idea of making everything out of stainless. Sorry for the temporary hijack....Rich

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#30

|

||||

|

||||

|

Quote:

With the max6675 I used you had to let it rest between sensor readings. Another thing I banged my head over. I really like that someone else is running with the BT idea, can't wait to see the final solution. I am also doing water injection as well to keep the EGT's down and will control that my mega. I may end up having to steal some of your ideas  . Wiring is def on of my biggest issues. The cool thing about the android is that you can log stuff, somethin I am sorely missing now. . Wiring is def on of my biggest issues. The cool thing about the android is that you can log stuff, somethin I am sorely missing now.For intance, I was running 1600F at WOT and recently I adjusted my timing and now my EGT's are far lower, but I don't have any logged datapoints to compare with.

__________________

http://superturbodiesel.com/images/sig.04.10.jpg 1995 E420 Schwarz 1995 E300 Weiss #1987 300D Sturmmachine #1991 300D Nearly Perfect #1994 E320 Cabriolet #1995 E320 Touring #1985 300D Sedan OBK #42 |

|

| Bookmarks |

|

|