|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

|

|

#1

|

||||

|

||||

|

Quote:

If the ALDA leaks like a sieve, forget any sort of fuel enrichment. People always fiddle with the ALDA instead of fixing the underlying problem: Leaks. Try pulling a vacuum on it with a mightyvac. It should hold vacuum just like any other vacuum device. It relies on boost pressure collapsing a set of metal bellows to enrich the fuel trim. Leaks reduce the enrichment and shift it much farther up the RPM range than it should be. The difference between the ALDA working properly and leaking is like night and day. It's an anti-smoke device, but it's also a REFINEMENT device. If it's working properly, there's no distinguishable difference with it removed, other than not rolling coal from a takeoff and much smoother and predictable control over the engine power output.

__________________

Current stable: 1995 E320 157K (Nancy) 1983 500SL 125K (SLoL) Gone but not forgotten: 1986 300SDL (RIP) 1991 350SD 1991 560SEL 1990 560SEL 1986 500SEL Euro (Rusted to nothing at 47K!) Gone and wanting to forget: 1985 524TD 167K (TotalDumpster™) [Definitely NOT a Benz] |

|

#2

|

||||

|

||||

|

Just so and one needn't any tools to check for ALDA leaks ~ just un hook the plastic pipe from the valve on the firewall and suck on it, apply your tounge ~ it *must* hold vacuum .

FWIW, the poor photo shows the overboost valve mis connected ~ the ALDA's pipe goes to the upper nipple, the pipe from the intake manifold goes to the downward facing, bottom nipple and yes, it makes a difference . When you blow through this valve there should be zero resistance, easy to clean in the kitchen sink using any strong liquid soap/spray cleaner then flush clear with tap water .

__________________

-Nate 1982 240D 408,XXX miles Ignorance is the mother of suspicion and fear is the father I did then what I knew how to do ~ now that I know better I do better |

|

#3

|

||||

|

||||

|

Nate - I am not sure how to interpret your last post. However I did go out and take a pic of my switchover valve ('81 300SD) and looked in the manual - because I forgot where the ALDA is.

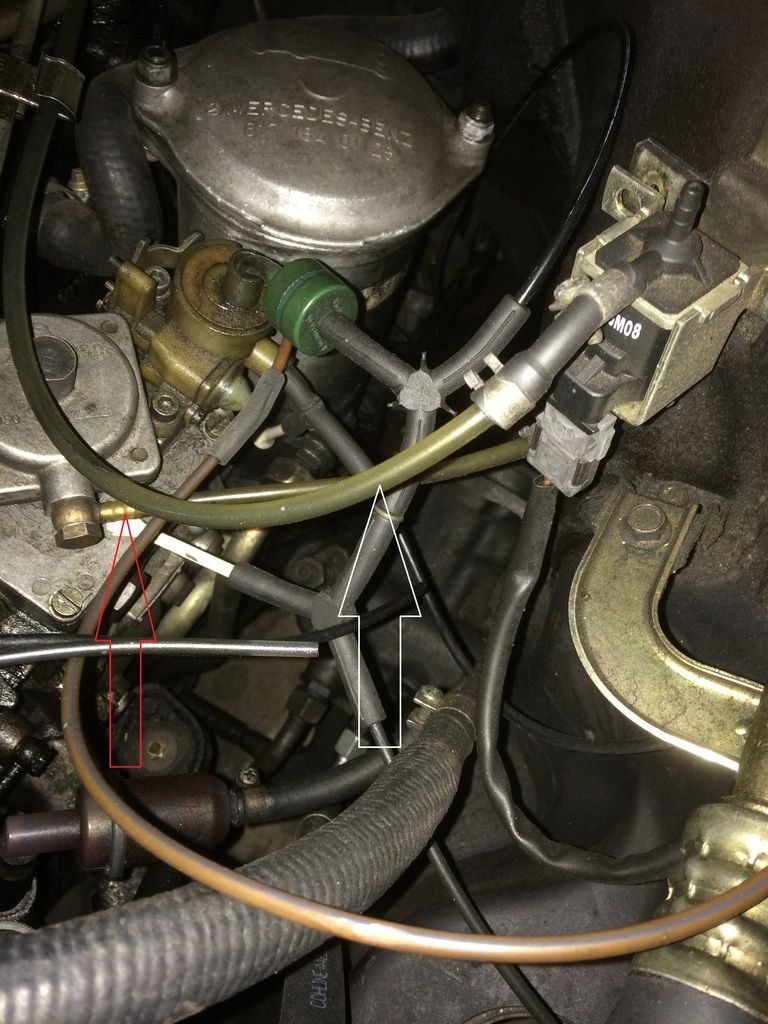

Here is what I found - the vac line on the bottom of the switchover valve definitely goes to the ALDA. The vac line on the top definitely goes over to the back of the valve cover; however the nipple is not on the valve cover as I had remembered - it is actually just to the passenger side of the back of the valve cover. I am not sure exactly what that nipple is attached to. If my FSM were not so difficult to use, I would try to find it. So in picture number one below you can see a red arrow pointing to the vac line going to the ALDA from the bottom of the switchover valve. The white arrow points to the vac line which travels over past the valve cover and attaches to a nipple there. In picture number two you can see where the top vac line attaches. Assume it is the same in the PO's vehicle.

|

|

#4

|

||||

|

||||

|

You have the two boost signal pipes switched .

The bottom one is supposed to connect to the back of the intake manifold's banjo bolt, you think it's the valve cover, it's not . These are NOT VACUUM LINES/PIPES ! . Do the vacuum test to the pipe that goes to the ALDA then blow through the valve and see how much resistance there is, the banjo bolt often clogs up over time and is easy to clean as are the plastic pipes....

__________________

-Nate 1982 240D 408,XXX miles Ignorance is the mother of suspicion and fear is the father I did then what I knew how to do ~ now that I know better I do better |

|

#5

|

||||

|

||||

|

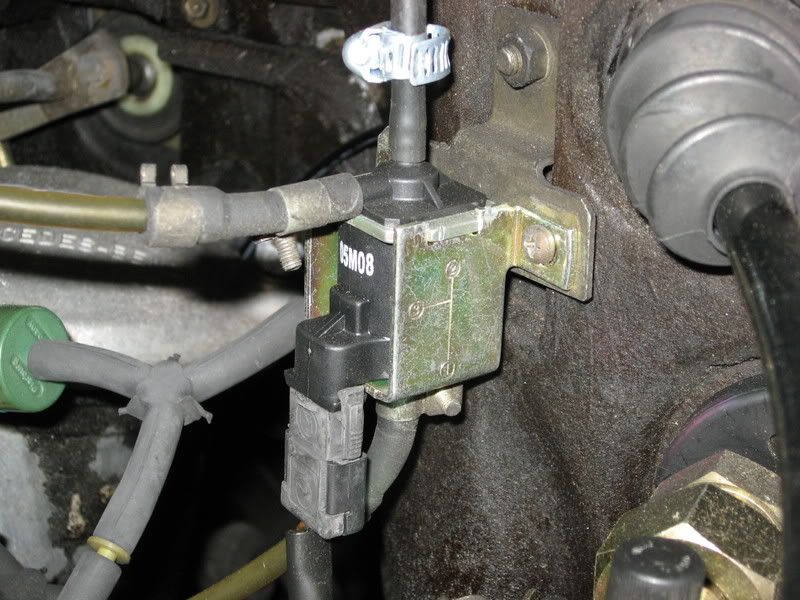

Well, I am confused. Looking at the pic of my original 1981 switchover valve (see below), I see that there are two nipples on the bottom where the elec connection is. The new one is not like that. So I really do not where those fool plastic lines go. I remember that I hooked them up wrong and could not get over 30mph. Then hooked them up like I have them now and got back the original power.

For some reason my FSM CD shows the bottom line going to the ALDA and the top going over to the banjo next to the valve cover and on that nipple. Guess my FSM was printed after they changed the design of the switchover valve. So my interpretation is: top - vertical nipple open; horizontal nipple connected to banjo on passenger side of engine. Bottom - connect elec plug and hook plastic line to ALDA which sits about atop the injection pump. What do you think? Old part in top pic and new replacement in bottom pic. Can't believe I kept pics. Just luck. The bottom pic shows the vertical nipple capped off but I finally removed it and it is now open to atmosphere which I think is right.

Last edited by tyl604; 03-21-2019 at 10:19 AM. |

|

#6

|

||||

|

||||

|

The FSM clearly shows the boost sense line from the manifold coming into the BOTTOM of the 3-port switchover valve and the ALDA being connected to the CENTER port with the TOP vented to atmosphere. The lines get convoluted on the drawing and can be hard to read, but the switchover valve is common to many other sources in later cars, and the port that is being switched is always the middle.

Because of how it works, the middle port is the one that is switched. If the ALDA is connected to the bottom port as Tyl shows, if the switchover valve is activated, the ALDA will not bleed off to atmosphere, it will just hold whatever pressure it was sent before the switch activated. Essentially rendering the valve pointless.

__________________

Current stable: 1995 E320 157K (Nancy) 1983 500SL 125K (SLoL) Gone but not forgotten: 1986 300SDL (RIP) 1991 350SD 1991 560SEL 1990 560SEL 1986 500SEL Euro (Rusted to nothing at 47K!) Gone and wanting to forget: 1985 524TD 167K (TotalDumpster™) [Definitely NOT a Benz] |

|

#7

|

||||

|

||||

|

Oops, sorry .

__________________

-Nate 1982 240D 408,XXX miles Ignorance is the mother of suspicion and fear is the father I did then what I knew how to do ~ now that I know better I do better |

|

#8

|

|||

|

|||

|

OK, I did just adjust the wastegate and I am now up to about 10 PSI. I know that a bit more would be advantageous. But, the awful retaining spring is something I don't want to have to reinstall again.

With 10psi, I still feel like I don't actually have a turbo. Many have pointed out that boost pressure without a functioning ALDA will not feel like the turbo is giving any power. With slightly only 10 PSI of boost, I'm thinking I should at least try bypassing the switchover valve at least to see if I get more power. I do have a boost gauge so I can watch it and make sure I don't over boost. |

|

#9

|

||||

|

||||

|

This is common practice on all my cars. Unless the banjo on the manifold clogs, I know I will always have a good boost signal.

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#10

|

||||

|

||||

|

As I remember 0-60 mph should be about 12 seconds.

|

|

#11

|

||||

|

||||

|

The wastegate is there to regulate boost pressure. You've already proven that it works because you were able to adjust it. You can't overboost unless the wastegate actuator fails, the sense line to it blows off or breaks, or the wastegate sticks closed.

A quick test to prove out the ALDA is to just remove it and go for a ride. If you slam your foot to the floor from a dead stop, or if you hold the brake and put your foot to the floor, you should see smoke. If you do, and the car still drives the same, that's probably all it's gonna do. These cars aren't rocketships. As has been said before in this thread, time your 0-60 WOT run. A/C off, flat piece of road.

__________________

Current stable: 1995 E320 157K (Nancy) 1983 500SL 125K (SLoL) Gone but not forgotten: 1986 300SDL (RIP) 1991 350SD 1991 560SEL 1990 560SEL 1986 500SEL Euro (Rusted to nothing at 47K!) Gone and wanting to forget: 1985 524TD 167K (TotalDumpster™) [Definitely NOT a Benz] |

|

#12

|

|||

|

|||

|

OK, I went out to switch the hoses to bypass the switchover valve and the plastic hoses are hard as rocks. What is the best way to detach and reattach without cracking them? Gentle heat with a heat gun?

BTW, when measuring 0-60 in my car I find it more appropriate to use the minute hand on my watch rather than the second hand. |

|

#13

|

||||

|

||||

|

If you use a small screwdriver, you can probably push the plastic/rubber hoses off the nipples.

Last edited by tyl604; 03-25-2019 at 08:46 AM. |

|

#14

|

||||

|

||||

|

Those plastic pipes are hard, that's why there are sort rubber bits at the switchover valve, just pull straight away from the valve, gripping the rubber .

originally the rubber bits had clamps to prevent them from blowing off under heavy acceleration . Remember : you need to connect the boost pressure gauge at the ALDA and no where else so you'll get the actual amount of pressure reaching the ALDA.... ? Did you suction test the ALDA yet ? .

__________________

-Nate 1982 240D 408,XXX miles Ignorance is the mother of suspicion and fear is the father I did then what I knew how to do ~ now that I know better I do better |

|

#15

|

||||

|

||||

|

Take an exacto knife and slit the rubber hose first. I broke a nipple on my VCV trying to pull the old rubber off.

__________________

1991 300D 2.5 "Rocinante" 2002 Golf TDI "Teen Spirit" -------------------- 1984 300D 1966 Mustang I6 3sp 1985 Mazda RX-7 GSLSE 1982 Toyota Supra 1977 Datsun 280z 1971 Datsun 240z |

|

| Bookmarks |

|

|