|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

#1

|

|||

|

|||

|

tool needed, cylinder liner removal tool for the 5 cylinder 617 diesel

Anyone have a cylinder liner removal tool for the 5 cylinder 617 diesel for rent/sale?

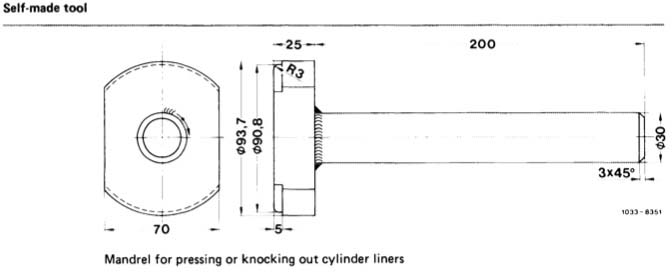

I need to remove the cylinder bore liners and looking for one like in the FSM. Thanks |

|

#2

|

|||

|

|||

|

I haven`t seen that tool, but I remember a thread from the earlier part of the year. the guy used a VW Rabbit CV joint, was the perfect size to fit.

Interesting DIY. post#9 where he mentions it. 616 rebuild options Self made tool http://www.peachparts.com/shopforum/attachments/diesel-discussion/46073d1184807649-sleeve-removal-tool-om617-92-cylinder-liner-tool.jpg Further reading. Remove/Install engine cylinder Sleeve/Liner Charlie

__________________

there were three HP ratings on the OM616... 1) Not much power 2) Even less power 3) Not nearly enough power!! 240D w/auto Anyone that thinks a 240D is slow drives too fast. 80 240D Naturally Exasperated, 4-Spd 388k DD 150mph spedo 3:58 Diff We are advised to NOT judge ALL Muslims by the actions of a few lunatics, but we are encouraged to judge ALL gun owners by the actions of a few lunatics. Funny how that works |

|

#3

|

||||

|

||||

|

Charlie that picture says a thousand words

Great link for the 616 project. I can't believe I missed it when it was a new thread... ...I see there's no update I wonder what happened.

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#4

|

||||

|

||||

|

Answer

__________________

ASE Master Mechanic https://whunter.carrd.co/ Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 2003 Volvo V70 https://www.boldegoist.com/ Last edited by whunter; 04-13-2012 at 03:24 AM. |

|

#5

|

||||

|

||||

|

most just take a mig welder and run a few beads down the sleeve, this shrinks the sleeve, and it falls out... of course it destroys the sleeve in the process...

__________________

John HAUL AWAY, OR CRUSHED CARS!!! HELP ME keep the cars out of the crusher! A/C Thread "as I ride with my a/c on... I have fond memories of sweaty oily saturdays and spewing R12 into the air. THANKS for all you do! My drivers: 1987 190D 2.5Turbo 1987 560SL convertible 1987 190D 2.5-5SPEED!!!  1987 300TD 2005 Dodge Sprinter 2500 158"WB 1994GMC 2500 6.5Turbo truck... I had to put the ladder somewhere! |

|

#6

|

|||

|

|||

|

I just removed a sleeve from my 1985 300D turbo (617.952 engine) that had failed at 330,000 mi. I did just the #1 cyl so far since badly scored. I dreaded this job having read few success stories and talk of special tools, which is probably why I left the car sitting for 3 years after I pulled the head and found the #1 piston cracked and beaten. I am not totally lackadasical, since I did buy a 1984 300D for $400 for its 123,000 mi engine, but ended up fixing its cracked front frame in 1 day's work (one son is driving it). I also bought two 60's Mopars that kept me busy, but finally got back to the Benz.

Of course I removed and stripped the engine to a bare block. I found the piston rings all broken in the #5 cyl. From what I read, the outer cylinders usually go first. I had been considering heating the block over a gas burner and dumping dry ice in the cylinders (w/ pistons to hold it) until I read of the weld bead trick. I ran 5 weld beads down the inside of the #1 liner, as suggested, using my $90 Harbor Freight wire-fed welder. I saw a little puffing from between the liner and block, so it might have helped, but the liner sure wasn't ready to fall on its own. I tried beating on what little lip I could rest a rod on at the bottom end. The liner would move around near the tool, but didn't shift at the far end. Finally, I folded it out a bit to seat a rod better and found it pulled away from the block easily. I then tried peeling it out with a long thin screwdriver driven between the liner and block and that was the trick. It folds away from the block easy with the screwdriver and then cracks since just cast iron. I just kept forcing the screwdriver down the gap and easily tore a slot down one side, then just folded the remainder in. It is just like removing thin ceramic. I will post a photo later. If I do the other 4 liners (still measuring, etc), I will skip the welder and just try the "pry w/ screwdriver" trick. Am I the only one who figured this out in 30 years? It isn't rocket science (my day job). |

|

#7

|

||||

|

||||

|

Quote:

2 things; very few people rebuld their Mrecedes Diesel Engines and I think most people would be worried about dinging up the Block bore; not knowing how easily the Liner Cracks. Let us know If the other 4 liners come out OK using the Screwdriver. I was wondering that if someone has a Welder why they do not Weld a piece of metal acrossed the inside of the Liner bore and use a Long Punch applied on the Piece of metal to beat out the liner?

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#8

|

|||

|

|||

|

Here is the promised photo of my removed cylinder liner and 2 tools. I will probably remove the other 4 the same way. I don't think the welder is required. The bore in the block is fine. That cheap steel screwdriver can't scratch cast iron. Note the groove at the top of the cylinder that locks the liner in place (per factory manual). I read that 86+ 300D engines (alum block) don't have a locking groove.

My current issue is deciding to keep or change the liners in cyl 2-5. I measure bores between 90.830 to 90.907 mm (crosswise & axial), whereas factory limit is 90.919 to 90.928 mm for cyl 2-5. Not only are they in spec, but some are even "too small". The main thing is machining the liners to match the pistons (~1.5 mil gap), so maybe the factory did that (no record of re-sleeve by prior owner). "Out of round" is 1 mil or less for cyl 2,3,4 (good) but 4 mil for cyl 5 (bad). I don't fully trust my measurements using a telescoping transfer gage and vernier micrometer (+/- 1 mil), since it is easy to get the gage cocked or for it to slip. I will try judging by the end gap of the new rings and gap of the pistons once I get them clean. |

|

#9

|

|||

|

|||

|

Updating, for those interested. I left my 1985 engine at the point above (1 liner out) since I hit a road-block on pistons. I now see turbo pistons for $135 ea on ebay, but will wait for a more reasonable price. I can wait years since I found an 1984 engine for $300 on craigslist and installed it. Ran it on the ground first, and no blow-by at all from the valve cover and the cam looks new w/ bright paint stripe (looking in oil filler hole). That is a better deal, since I now have many spare parts (starter, turbo, ...). Not driving yet since I need a regular air filter housing and tubing (1985 is unique) and busy rebuilding a 64 Valiant & 65 Dart.

|

|

#10

|

||||

|

||||

|

Quote:

__________________

85 300D turbo pristine w 157k when purchased 161K now 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#11

|

||||

|

||||

|

Quote:

You see a similar instruction on some large Engines as a way to remove Valve Seats inserts by running a welding bead on the Valve Seat Face. When the Metal solidifies the OD of the Valve Seat Insert shrinks and loosens it.

__________________

84 300D, 82 Volvo 244Gl Diesel |

|

#12

|

||||

|

||||

|

Wouldn't it be easier to do this this a stick / arc welder?

I mean how on earth are you going to get a MIG torch down the length of a liner?

__________________

1992 W201 190E 1.8 171,000 km - Daily driver 1981 W123 300D ~ 100,000 miles / 160,000 km - project car stripped to the bone 1965 Land Rover Series 2a Station Wagon CIS recovery therapy! 1961 Volvo PV544 Bare metal rat rod-ish thing I'm here to chat about cars and to help others - I'm not here "to always be right" like an internet warrior Don't leave that there - I'll take it to bits! |

|

#13

|

|||

|

|||

|

You might already have one. It's called a welder. Simply lay a bead bottom to top or top to bottom and the liner will come right out.

Putting in the new liner is a job for a competent automotive machinest, if you're not one with access to a boring bar. A stick is the easiest. Doesn't really matter what rod you choose as long as you can run a bead with it.

__________________

2001 SLK 320 six speed manual 2014 Porsche Cayenne six speed manual Annoy a Liberal, Read the Constitution |

|

#14

|

||||

|

||||

|

Recycled

for new members

__________________

ASE Master Mechanic https://whunter.carrd.co/ Prototype R&D/testing: Thermal & Aerodynamic System Engineering (TASE) Senior vehicle instrumentation technician. Noise Vibration and Harshness (NVH). Dynamometer. Heat exchanger durability. HV-A/C Climate Control. Vehicle build. Fleet Durability Technical Quality Auditor. Automotive Technical Writer 1985 300SD 1983 300D 2003 Volvo V70 https://www.boldegoist.com/ |

|

#15

|

|||

|

|||

|

Some of you are suggesting ' iffy ' procedures.... and it seriously looks like you have not clicked on Whunter's url reference.... OR read the actual FSM on this procedure...

If you have the correct size mandrel...... use DRY ICE to cool the sleeve well just prior to using the factory recommended tool.... this is not a complicated or hard procedure. Some people do not believe that ' simple ' can be the most effective ... and safer... method... There are many posts in the archives by people who have used the standard procedures with predictable success.

__________________

1980 240d , chain elongation, cam marks reference: http://www.peachparts.com/shopforum/diesel-discussion/10414-help-i-need-check-stretch.html http://www.peachparts.com/shopforum/diesel-discussion/305365-9-degrees-chain-stretch.html evap fin cleaning: http://www.peachparts.com/shopforum/diesel-discussion/156207-photo-step-step-post-showing-w123-evaporator-removal-1983-240d-1982-300td.html?highlight=evaporator A/C thread http://www.peachparts.com/shopforum/diesel-discussion/297462-c-recommendations-mb-vehicles.html |

|

| Bookmarks |

|

|