|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

#106

|

||||

|

||||

|

Quote:

The way the MB fittings are made its all but impossible to reuse the barb to attach a new hose. The ferrule appears to be welded on.

__________________

Current Stable

|

|

#107

|

||||

|

||||

|

Quote:

Quote:

Quote:

I planned to replace the hose regardless because the existing hose is pretty much original. So since I'm doing that, I'll just have them add a couple of inches in length. BTW - I have an extra GH rear plate with a slightly buggard thread (but still holds fine) on the center bolt hole that I can sell for cheap. I can also shape/bend another stock manifold fitted to Rollguy's Gen 1 Sanden bracket and have the a/c shop replace the additional hose since I'm doing mine. If interested, PM me. .

__________________

1983 123.133 California - GreaseCar Veg System Last edited by DeliveryValve; 04-30-2013 at 08:29 PM. |

|

#108

|

||||

|

||||

|

That is exactly how I do it when the fittings and hose size don't match. I was just interested how DeliveryValve was going to do it.

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#109

|

|||

|

|||

|

DeliveryValve,

Thanks for your very helpful post and photos. I had the same plan and thought the factory hoses would just fit. You proved they do with slight bending. I have a QD head (6 bolt), which looks identical to your GH head, except uses O-rings on the "GM Pad". I bought new on ebay for ~$20 plus ~$8 pressure relief valve. The QC head looks the same w/o the PRV hole. It is OK to have a Sanden up to 90 deg off vertical, so this design should work. I have the SD7H13 (shorty) compressor, which is ~1" shorter than your SD7H15 and thus closer to the R4 "pancake". I was waiting for my son to bring his 300D home at Spring Break to install the Sanden, but he ended up flying home. I don't want to put on my 300D since I will use up my Harrisons there and deal with their failures , which he can't. For others, I post a photo of many Sanden heads, though it doesn't show my QD head. Note that some are for 5-bolt (SD5) and some for 6-bolt (SD7) Sandens. The Q head looks like it would work great with a 5-bolt Sanden. |

|

#110

|

|||

|

|||

|

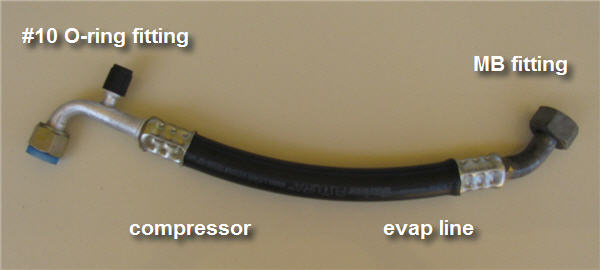

Posting here to keep with DeliveryValve's 4-19-2013 post, since a similar approach. I typed a detailed description of my install, but the website ****'ed me and lost it all when I hit "post" (happened to you?), so I'll just list the highlights w/ photos. Ask questions if you need details.

Sanden SD7H13 "shortie" w/ QD head, connecting to factory A/C tubes. Required spacers and special bolts, better to use an H15 (or 708) as intended. The 0.460" axial length savings wasn't needed. Much bending of tubes required, as DeliveryValve. 2.5"D hole added to plate, not worth the effort for slight weight savings. Disconnected and flushed all lines, new drier, used engine's vac pump then hand pump Duracool (3 cans) & their oil (PAO 68), AC works great, no compressor vibrations. The new bracket bent my damper indicator pin (another post) Simpler to buy Rollguy's full kit w/ new hoses and not muck around like I did. Last edited by BillGrissom; 11-11-2013 at 03:00 PM. |

|

#111

|

||||

|

||||

|

Nice job Bill. I am happy to see it work out for you using the factory hoses. Part of the reason I made the kit NOT using the factory hoses, is the fact that most of them are as old as the car, and need to be replaced anyway. Another is that I was not sure that the factory hose assy. would work wit the adjustable compressor. With the Gen 1, the compressor is fixed, so mounting the factory hose assy. to the compressor somehow would be easy. It appears that you have solved the mounting problem....Rich

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#112

|

|||

|

|||

|

Rich,

I didn't make any changes to the compressor mounting. Using the shorter compressor only moved the rear ports forward 0.46", so the factory hoses would have worked fine with a regular Sanden (DeliveryValve's similar setup). The front of my compressor and V-belt are in the same place. I used a new Goodyear Gatorback 15382 belt (11AV0955) I found in my "V-belt box". It just barely fits (what I wanted). I am ~1/3 on the adjustment bolt (I did tighten jam nut after photos). If I went to full adjustment, the suction tube would probably hit an oil cooler tube, but I could bend that more, as long as it doesn't push the oil cooler hose too close to the power steering belt (been there, not good). |

|

#113

|

||||

|

||||

|

Quote:

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#114

|

|||

|

|||

|

I got you. I was able to get that thin strap on the high-pressure tube under a bolt on the Sanden. I doubt it adds much support, that was just to look finished. That bolt should be in the same place on DeliveryValve's compressor, since also a 6-bolt type. I don't notice any compressor vibration at all, relative to the engine. Not sure why an adjustable bracket makes a difference. Once you bolt it tight, the compressor has a solid 3-pt mount to the plate - 2 upper flange bolts and lower slotted brace bolted tight. I use the adjustment bolt just for tensioning, it isn't relied on once bolted down.

I also wonder about the reliability of my factory hoses. The high-pressure one has swollen outer rubber around the ferrule (from oil drips?), and even got a little torn in working it around the bracket. However, I think it has an inner plastic liner that actually holds the pressure (barrier hose). If I ever need to replace it, I might try cutting off the ferrules and recrimping new hose & ferrules. I have an AC crimper and parts, but I don't know what U.S. sizes might work with these Euro fittings. Wheeler Dealers (British) had an episode recently where they needed a hose for a Lamborghini and the hose shop guy was able to match it, but it took a little research. There is a lot of variety even within Europe. |

|

#115

|

||||

|

||||

|

Quote:

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#116

|

|||

|

|||

|

Quote:

I do have an extra factory hose to play with. It came on my used engine, but they broke off the discharge tube on the passenger side when pulling the engine at PickNPull. If I change to a modern parallel-flow condenser wouldn't matter since need to change somewhere to a U.S. tube w/ O-ring fittings. I mis-stated. My adjuster has only ~1/3 left, so even at max my suction tube probably wouldn't hit the oil cooler tube. Also good I used the shortest V-belt I could get on the pulleys. Re oils, from my recent reading PAO 68 seems like the best oil to use for any refrigerant. Hella makes it, and usually comes w/ uV dye. Unlike PAG, it doesn't absorb moisture. It even absorbs less than mineral oil. It also tends to stay put in the compressor, so doesn't coat the condenser and evaporator as much (lowering heat transfer). You can find on ebay, or buy from Duracool as their "AC Chill" which I did since buying more cans of their HC refrigerant, plus their price was a bit cheaper than ebay. I haven't read that it affects rubber hoses, but shouldn't since you can add it to existing mineral oil or PAG. It is also supposed to improve the efficiency of the compressor. It does cost a bit, but I only needed 6 oz for my Sanden compressor, so can do ~5 retrofits with the bottle. |

|

#117

|

|||

|

|||

|

please how can i get this kit for my w123 300d already i have harisson r4 and i want to change it with sanden

|

|

#118

|

|||

|

|||

|

Nazonad,

There is a more recent thread on Rollguy's Sanden brackets. Search for it. You can also PM him directly.

__________________

1984 & 1985 CA 300D's 1964 & 65 Mopar's - Valiant, Dart, Newport 1996 & 2002 Chrysler minivans |

|

#119

|

|||

|

|||

|

Hi I really like what you did with this sanden. Old can I take one for my w123 300d. Am living in Algeria. Can you send me this system how much and how can I receive it

|

|

#120

|

||||

|

||||

|

I don't think I am able to deal with shipping and payment to/from Algeria, sorry.

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

| Bookmarks |

|

|