|

|

|

|

|

|

|

|

|

|

|

|||||||

|

|

|

LinkBack | Thread Tools | Display Modes |

|

#46

|

||||

|

||||

|

Quote:

Did you have a post on the PF condenser install? You'd changed your AC system quite a bit since 2013. I'd be interested in a description of the changes made and performance differences as a result of each change.

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#47

|

||||

|

||||

|

Quote:

12-0437C - PF Condenser (14 X 22.5) At that particular moment, sometime in 2007, AC kits didn't offer any other size that would work in a w123 when I needed one. I posted the entire AC condenser and rebuilt R4 compressor install on the old schumanautomotive forum website. That was before that site went all paranoid and made everything private few years after 2007. At the time, I thought the cooling was adequate with Freeze 12. But ultimately I swapped it out with R12 because I couldn't stand the drag the higher pressure Freeze 12 was putting on the R4 Compressor. As soon as I made the change, I remember the cooling went from low 40's/high 30's F with Freeze 12 down to low 30's with the R12. It froze me out sometimes with temps hovering at 32° out of the vents. But when the car sat awhile in the 100° plus sun, I could feel I had a circulation issue, which brought me to the main topic in this thread. This endeavor was spearheaded by the untimely death from a catastrophic internal destruction of the rebuilt R4 that was installed 5 years earlier. Quote:

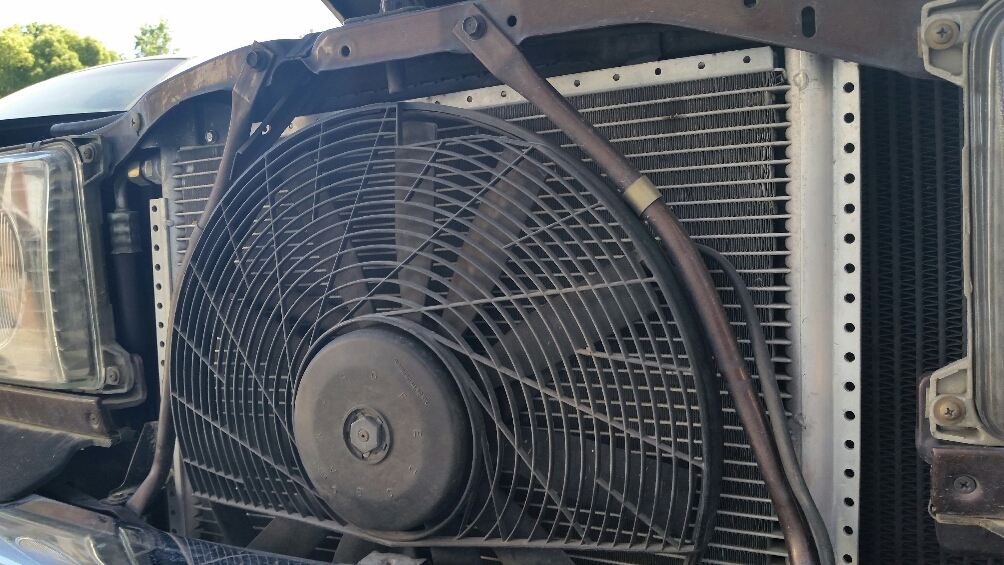

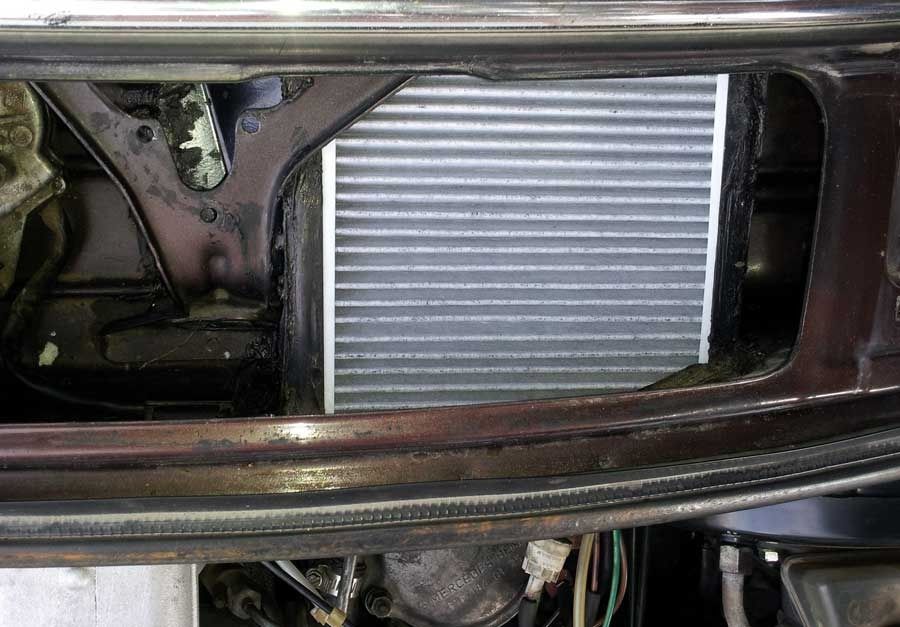

2) As I mentioned earlier, I had a compressor failure which blew up internally. Not a pretty sight, basically sending shrapnel through the lines. I was forced replace the majority of the lines and replacing the condenser as well from the shrapnel contamination. I would end up buying a cheap eBay 16x22 inch condenser. Slightly bigger than the 14x22.5 AC kits condenser I had. I would also end up installing a later 2nd gen w126 electric fan to improve the air flow.  Here is the thread: 86-91 W126 aux fan into W123 300D ?? As of right now, I would say the eBay condenser and 2nd gen w126 fan has done it’s job and cooled very well. I can’t really say if performance has improved upon what I had before, because it is all one system working together. But would guess it has. 3) One of my main concerns was the evaporator getting clogged up with dirt again. So I made a modification to the firewall and installed a fresh air cabin filter.   Here is the thread: w123 Outside Air Cabin Filter addition I have to say this mod has been working out really well. I am using a basic 2005-2014 Mustang cabin filter. I found the charcoal activated filter types restrict the air flow a bit. 4) The other modification I did to the system had to do with the recirculation flaps. I live in an area with some dairy farms. If you know what I am talking about, it can get stinky. Sometimes, my system would draw in fresh air when I want them closed near those farms. I made an override switch. Which also helps with cooling down the cabin quicker occasionally.  Here is the thread: w123 HVAC recirculation modification 5) Since I had a catastrophic compressor failure, I opted to go with a 7 cylinder Sanden 7h15 compressor using R12 refrigerant and Rollguys First Gen bracket kit. Here it is mocked up on my spare motor.  I do feel the Sanden is a smoother operating compressor vs the R4. But performance wise, engine drag maybe the same and I am getting the same 32° F vent temps as before. So I feel I haven’t really upgraded in that aspect. Issues… I do have issues with belt stretch and is trying to find a sweet spot on the Contitech belt size. I also was kind of stubborn and decided to try to make the hoses somewhat factory looking using the original A/C hose manifold to the connect to the compressor. As I type this, the manifold has cracked a second time at the braze repair from the first crack that it suffered previously. I have now lost my second 2.9 lbs charge of R12 to the atmosphere. I will have to determine if the crack was due to a faulty braze repair or was due to the use of a poorly modified R4 manifold. I hope I answered the question you were asking.

__________________

1983 123.133 California - GreaseCar Veg System Last edited by DeliveryValve; 07-19-2016 at 05:09 PM. |

|

#48

|

||||

|

||||

|

Just to let you know, I have a stack of R4 manifolds. They are free for the taking, or you pay for the shipping and you can have as many as you need. If I were using the stock manifold, I would weld on a male fitting like I do for the pipe on top of the engine. That way the rubber hose portion can be disconnected if replacement is needed. Of course I would replace the hose anyway, and crimp on the proper fitting to screw on the manifold. I have everything to do so, it is just that the systems I do, I run a new hose above the engine, and not below.

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#49

|

||||

|

||||

|

Another thought, your manifold cracking could be because of the lack of brackets holding the manifold to the engine and/or compressor. Vibration is a major contributor to all the component failures of this system, so I can't imagine the stock manifold lasting without being tightly bolted to something. That is also the reason I use steel fittings on everything. There may be one exception, it is an inline charge port fitting for r12 that never sees vibration (I can't find them in steel).

__________________

All Diesel Fleet 1985 R107 300SLD TURBODIESEL 2005 E320 CDI (daily) LOTS of parts for sale! EGR block kit http://www.peachparts.com/shopforum/diesel-discussion/355250-sale-egr-delete-block-off-plate-kit.html 1985 CA emissions 617 owners- You Need This! Sanden style A/C Compressor Mounting Kit for your 616/ 617 For Sale + Install Inst. Sanden Instalation Guide (post 11): http://www.peachparts.com/shopforum/diesel-discussion/367883-sanden-retrofit-installation-guide.html |

|

#50

|

|||

|

|||

|

How much room between your w126 aux fan and your parallel flow condenser do you have? I just swapped to a parallel flow but my stock fan shroud is about an inch from the condenser. I am thinking about switching to the oversized fan next time one shows up at the junkyard

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#51

|

||||

|

||||

|

Quote:

Your choice to not use the manifolds was the correct choice, I was just stubborn. But I do think I will continue to be stubborn and make this work. In this thread, I posted about the crack and using Envirosafe. Enviro-Safe r12a users, Q's on moisture.. I was thinking I may end up with another crack and I would rather leak something more environmental friendly into the atmosphere. Oh well I guess I should of followed my gut. Anyways, vibration is an issue. I did make a bracket to hold the manifold line down. That was not shown in the mock up picture. But I think my fabricated sheet metal bracket is not strong enough.  I do have another idea for another bracket, just got to fabricate it. .

__________________

1983 123.133 California - GreaseCar Veg System |

|

#52

|

||||

|

||||

|

Quote:

Here is some discussion about it. 86-91 W126 aux fan into W123 300D ?? .

__________________

1983 123.133 California - GreaseCar Veg System |

|

#53

|

||||

|

||||

|

It seems a good idea to reduce the mass of the current manifold (which looks huge in the pic) by making a custom one. Why be stubborn?

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#54

|

||||

|

||||

|

It was basically a challenge I had to myself to make the current parts I have work. You start by buying a rear compressor head plate, then replace the hose on the manifold and next you think your all in on that design. At this point, I can say I tried it. I will evaluate my next move.

__________________

1983 123.133 California - GreaseCar Veg System |

|

#55

|

||||

|

||||

|

OK, I see. I would have done the same in the same situation.

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#56

|

|||

|

|||

|

Quote:

__________________

'85 300D - federal spec, built in late 84. 85 300D Complete AC System Rebuild |

|

#57

|

||||

|

||||

|

Thanks.

__________________

1983 123.133 California - GreaseCar Veg System |

|

#58

|

||||

|

||||

|

Quote:

.

__________________

1983 123.133 California - GreaseCar Veg System |

|

#59

|

||||

|

||||

|

Hey deliveryvalve, what does it take to remove the stock condenser in my 85? I have just about everything removed: aux fan out, driver head light out, radiator and oil cooler unmounted and pushed back. The condenser is locked in place by the top core support, bottom supports and head light brackets left and right, and won't come out the front or back. Does the bumper and the lower cross members have to come out? The FSM is no use, instructions for condenser removal is only in ACC I and it simply does not work.

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

#60

|

||||

|

||||

|

Quote:

"For the record, the condenser does NOT like to come out the front. If you want to keep your condenser in good shape after you remove it, don't try pulling it out the front. I had to do a little bending and scraping to get mine out that way (fortunately for me, I'm tossing it anyway)."

__________________

85 300D turbo pristine w 157k when purchased 167,870 July 2025 83 300 D turbo 297K runs great. SOLD! 83 240D 4 spd manual- parted out then junked |

|

| Bookmarks |

|

|